How accurate is a CNC plasma cutter?

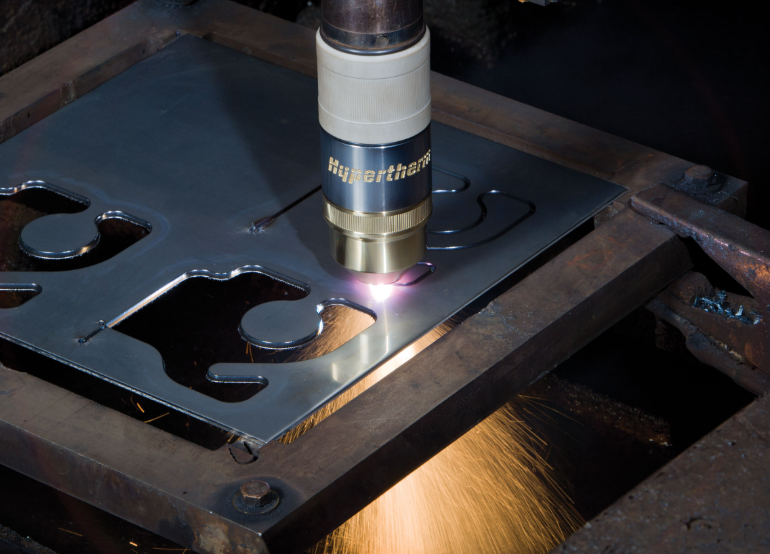

Understanding CNC Plasma Cutting CNC plasma cutting stands as a pivotal technology in modern fabrication, revolutionizing how industries handle metal cutting tasks. This process involves directing a plasma torch under computer control to cut through various types of materials. The key advantage of CNC plasma cutting lies in its ability to cut through diverse metals […]