Polysilicon typically exhibits a tensile strength in the range of 100 to 500 MPa

Production Process of Polysilicon

The production process of polysilicon is crucial as it determines the purity and quality of the end product, directly impacting its strength and functionality. Various methods exist to produce polysilicon, each with its unique steps, efficiencies, and purities.

Tongwei Process

The Tongwei process is one of the most common methods used for producing high-purity polysilicon. It begins with metallurgical-grade silicon, and through a series of chemical reactions, transforms it into high-purity polysilicon.

- Trichlorosilane Formation: The process starts with the conversion of metallurgical-grade silicon into trichlorosilane (TCS) by reacting with hydrogen chloride. It then undergoes purification to remove impurities.

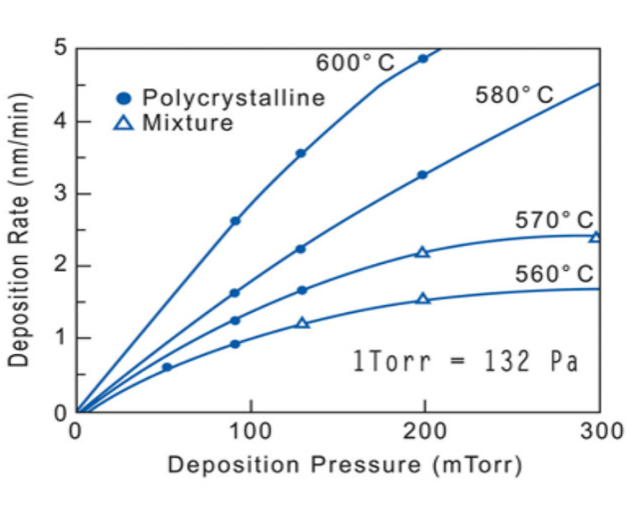

- Chemical Vapor Deposition: The purified TCS is then deposited in a chemical vapor deposition (CVD) reactor, where it decomposes at high temperatures to deposit elemental silicon onto a silicon rod.

- Rod Extraction: After the deposition, polysilicon rods are extracted, broken down, and then refined to attain the desired level of purity. The final product serves a plethora of applications such as in solar cells and semiconductor devices.

Fluidized Bed Reactor Process

- Silane Gas Introduction: In this method, silane gas is introduced into a fluidized bed reactor containing silicon seed particles.

- Silicon Deposition: The silicon deposits on the seed particles until the particles grow to a specified size.

- Final Purification: The harvested polysilicon undergoes further purification processes to meet the quality standards required for applications like MEMS devices and electronics.

Upgraded Metallurgical-Grade Silicon Process

- Direct Carbothermic Reduction: Metallurgical-grade silicon undergoes direct carbothermic reduction to remove impurities and increase silicon purity.

- Refinement: The refined silicon then undergoes additional processes to achieve the desired purity level suitable for photovoltaic applications, leading to the development of photovoltaic cells.

- Applications: The polysilicon produced through this process mainly finds its use in the production of solar cells, serving as a critical component in harnessing renewable energy from the sun.

Structural Properties of Polysilicon

Polysilicon, with its unique structural properties, plays a pivotal role in many modern technologies, especially in solar cells and semiconductors. The structural properties, particularly the crystal structure and grain boundaries, significantly impact its electrical and mechanical characteristics.

Crystal Structure

The crystal structure of polysilicon is one of its defining structural properties, impacting its strength and electronic properties. Polysilicon, unlike monocrystalline silicon, consists of multiple small, differently oriented crystal grains.

- Formation and Characteristics: During the formation of polysilicon, numerous crystals begin to grow independently and eventually merge, forming grain boundaries. These boundaries can impact the movement of charge carriers, influencing the electrical properties of polysilicon.

- Impact on Properties: The crystal structure, due to its granular nature, can introduce sites of weakness, influencing the mechanical strength and reliability of the material in various applications such as in semiconductor devices.

Grain Structure and Boundaries

Grain structure and boundaries in polysilicon are crucial aspects that dictate its behavior and compatibility with different applications.

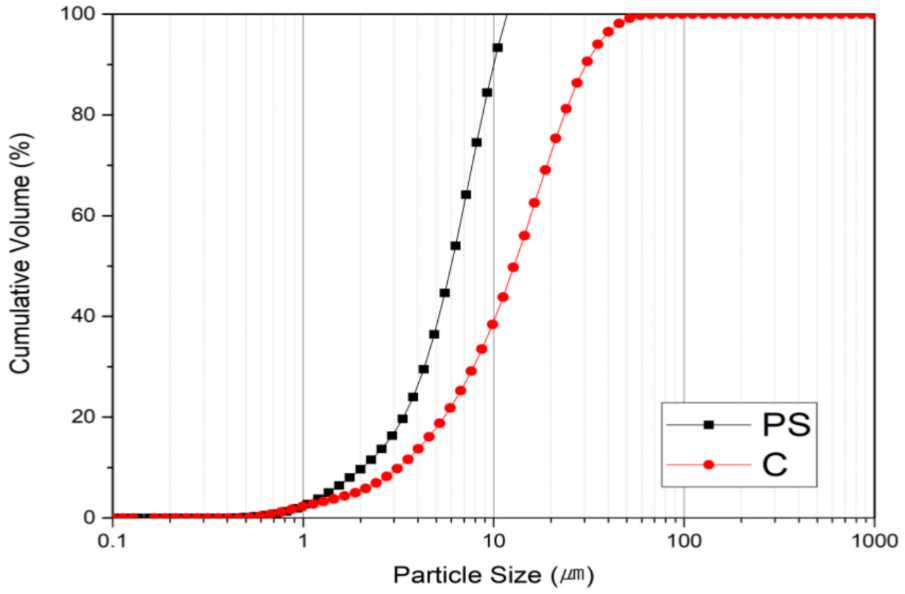

- Grain Size and Distribution: The grain size and its distribution in polysilicon can vary widely, affecting its performance in electronic applications. Larger grains usually result in better material properties due to fewer grain boundaries, reducing electron scattering.

- Boundary Properties: Grain boundaries act as barriers to electron movement, impacting the electrical conductivity of the material. Managing and controlling grain boundaries is thus vital in optimizing polysilicon for applications in photovoltaic cells.

- Optimization: Developing methodologies to control and optimize the grain structure and boundaries is essential for enhancing the performance of polysilicon in various domains like solar energy and microelectronics, allowing for advancements in sustainable energy solutions and technological innovations.

Mechanical Properties of Polysilicon

The mechanical properties of polysilicon, such as tensile strength, compressive strength, and fracture toughness, are vital in determining its suitability and performance in various applications, like in semiconductors and solar cells.

Tensile Strength

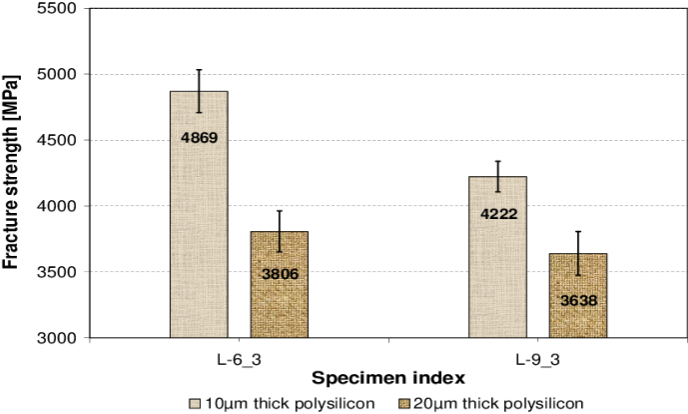

- Measurement and Importance: Scientists assess the tensile strength of polysilicon through standard test methods, determining its ability to withstand loads without failing. This property is crucial for ensuring the durability and reliability of polysilicon in applications like Microelectromechanical Systems (MEMS).

- Factors Influencing Tensile Strength: Grain size and orientation in polysilicon significantly impact its tensile strength.

Compressive Strength

Compressive strength refers to the capacity of a material to resist forces or loads that tend to reduce size.

- Testing and Relevance: Through meticulous testing, the compressive strength of polysilicon is evaluated, defining its ability to resist deformation under compression. High compressive strength is essential in maintaining structural integrity in devices like solar panels and integrated circuits.

- Role in Device Performance: Understanding and optimizing compressive strength are crucial in enhancing the performance and lifespan of polysilicon-based devices, ensuring stability and resilience against mechanical stresses in operational environments.

Fracture Toughness

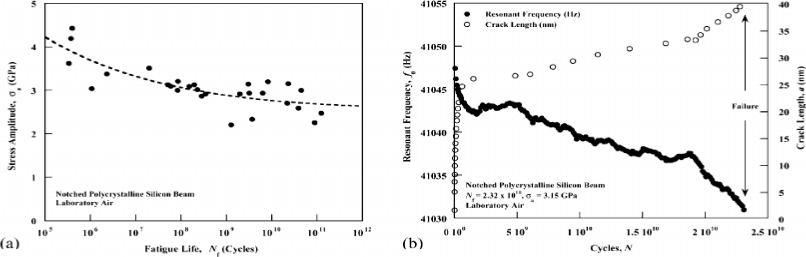

Fracture toughness is a critical property that describes the ability of a material containing a crack to resist fracture.

- Evaluation and Significance: The fracture toughness of polysilicon is critically analyzed to assess its resistance to the propagation of cracks. High fracture toughness is pivotal in preventing failure in applications such as photovoltaic cells.

- Influence of Microstructure: The microstructure of polysilicon, particularly grain boundaries, plays a significant role in determining its fracture toughness.

Electrical Properties of Polysilicon

The electrical properties of polysilicon, including electrical conductivity, charge carrier mobility, and the impact of dopants, are critical in defining its behavior and efficiency in electronic applications such as semiconductors and solar cells.

Electrical Conductivity

Electrical conductivity measures how easily electricity can pass through a material, and it’s one of the key properties for polysilicon when used in electronic applications.

- Measurement and Relevance: Scientists conduct precise tests to determine the electrical conductivity of polysilicon, which is crucial for its effective use in electronic devices. Higher electrical conductivity ensures better performance in devices like transistors and solar panels.

- Factors Influencing Conductivity: The grain structure and the presence of impurities can significantly affect the conductivity of polysilicon.

Charge Carrier Mobility

Charge carrier mobility is crucial as it represents how quickly carriers can move through a semiconductor material under the influence of an electric field.

- Evaluation and Importance: Careful assessment of charge carrier mobility in polysilicon is essential to understand its efficiency in conducting electric charge, which directly impacts the speed and reliability of electronic devices such as integrated circuits.

- Role in Device Efficiency: Optimizing charge carrier mobility is fundamental in enhancing the efficiency of polysilicon-based devices, allowing for faster and more reliable electronic components.

Impact of Dopants on Electrical Properties

- Doping Process and Outcomes: By introducing specific elements as dopants into polysilicon, its electrical properties like conductivity and charge carrier concentration can be manipulated, allowing for the creation of tailored electronic components.

- Applications and Developments: Understanding the impact of dopants is pivotal for developing advanced polysilicon applications, contributing to innovations in microelectronics and renewable energy technologies.

Applications of Polysilicon

Polysilicon serves as a fundamental material in a multitude of applications, facilitating advancements in various fields such as renewable energy and technology. Its distinct properties make it a material of choice for solar cells, semiconductor devices, and Microelectromechanical Systems (MEMS).

Solar Cells

- Production and Efficiency: Polysilicon solar cells are fabricated through intricate processes, and their efficiency in converting sunlight to electricity is paramount for the proliferation of solar energy.

- Advancements and Sustainability: The continual development of polysilicon solar cells is crucial in promoting sustainable energy solutions. These advancements are pivotal for reducing dependency on fossil fuels and mitigating climate change impacts.

Semiconductor Devices

Polysilicon is indispensable in the creation of semiconductor devices, serving as a primary material in the development of various electronic components.

- Integration and Performance: Polysilicon is integrated into semiconductor devices such as transistors and integrated circuits, where its electrical properties are vital for the optimal performance of these components. Enhancements in polysilicon can lead to the development of more advanced and reliable semiconductor devices.

- Innovation and Technology Development: The use of polysilicon in semiconductor devices is integral for technological innovations, enabling the development of more sophisticated electronics and contributing to progress in fields like communication and computing.

Microelectromechanical Systems (MEMS)

Microelectromechanical Systems, or MEMS, utilize polysilicon in constructing miniature mechanical and electro-mechanical elements.

- Fabrication and Applications: Polysilicon is crucial in the fabrication of MEMS due to its mechanical and electrical properties, allowing the production of components like sensors and actuators. The applications of MEMS are vast, spanning across sectors like healthcare, automotive, and consumer electronics.

- Advancements and Potential: The advancements in MEMS technology, fueled by the properties of polysilicon, hold immense potential for creating more efficient and versatile microsystems, opening doors to new possibilities and solutions across different domains.

Comparison with Other Materials

When comparing polysilicon to other materials like monocrystalline silicon, amorphous silicon, and silicon carbide, it’s crucial to examine their unique properties and applications to understand the advantages and disadvantages of each material.

Monocrystalline Silicon

Monocrystalline silicon is a single-crystal form of silicon that is characterized by its high purity and efficiency.

Amorphous Silicon

Amorphous silicon lacks a defined crystal structure, making it versatile for certain applications like thin-film solar cells.

Silicon Carbide

Silicon carbide is a compound of silicon and carbon, known for its hardness and high thermal conductivity, making it ideal for high-power, high-frequency, and high-temperature applications.

Comparison Table

| Property | Polysilicon | Monocrystalline Silicon | Amorphous Silicon | Silicon Carbide |

|---|---|---|---|---|

| Crystal Structure | Polycrystalline | Single-crystal | Amorphous | Covalently Bonded Network |

| Electrical Conductivity | Moderate | High | Low | High |

| Thermal Conductivity | Moderate | High | Low | Very High |

| Hardness | Moderate | Moderate | Low | Extremely High |

| Cost | Low to Moderate | High | Low | Moderate to High |

| Main Applications | Solar Cells, Semiconductor Devices, MEMS | High-Efficiency Solar Cells, Semiconductor Devices | Thin-Film Solar Cells, Displays | Power Electronics, LEDs, Heating Elements |

Evaluation and Implications

Understanding the distinct properties and applications of polysilicon, monocrystalline silicon, amorphous silicon, and silicon carbide is pivotal for selecting the appropriate material for specific needs and applications.