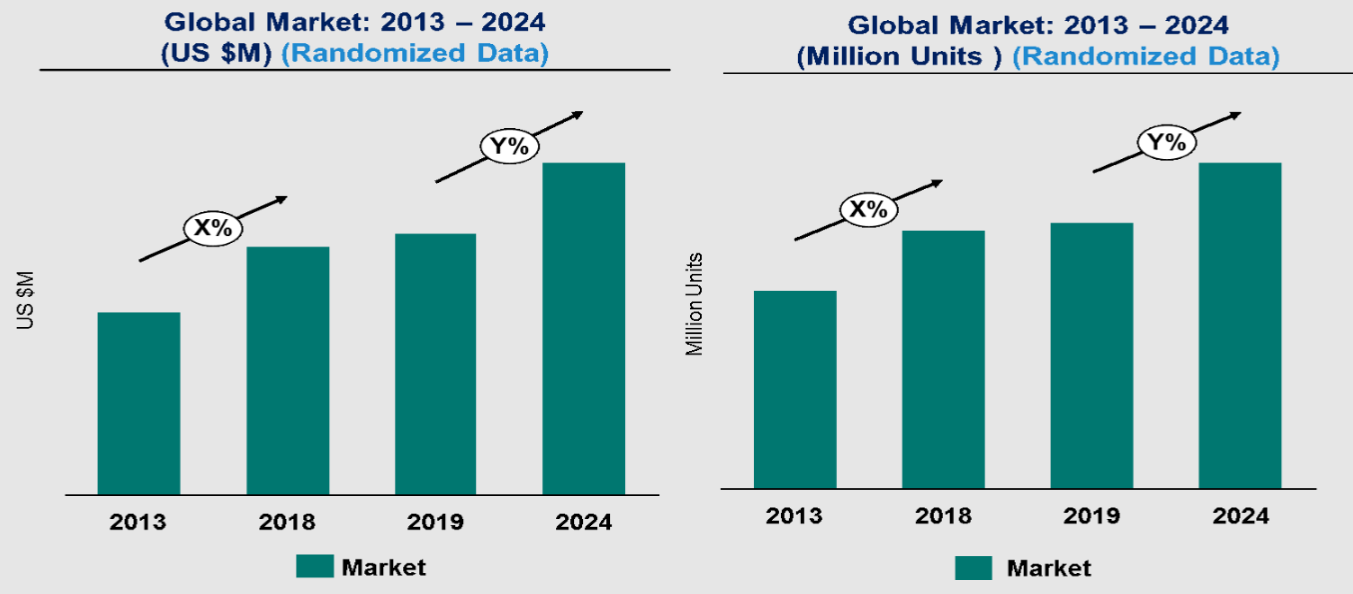

The market trend in polysilicon showcases a growing demand due to solar energy expansion and semiconductor industry growth.

Historical Market Overview

Evolution of the Polysilicon Market

Polysilicon’s Initial Introduction

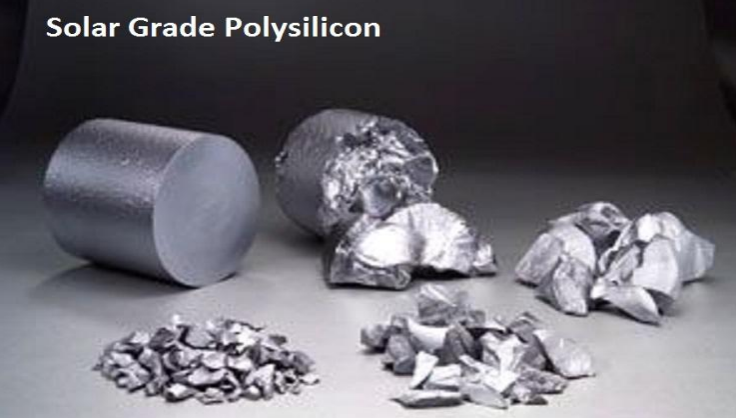

Polysilicon, also known as polycrystalline silicon, was first introduced in the early 1950s as a primary material for the burgeoning semiconductor industry. By the 1980s, its importance had skyrocketed, mainly driven by the rapid growth of the electronics sector.

The Shift to Renewable Energy

In the 1990s and 2000s, the demand for polysilicon took another leap with the rise of the solar photovoltaic (PV) industry. As solar panels became more popular and countries started investing in renewable energy, the need for high-quality polysilicon surged. By 2008, solar applications consumed approximately 90% of the global polysilicon supply.

Technological Advancements in Production

Advanced manufacturing methods, such as the Siemens process and fluidized bed reactor, were developed in the 1970s and 1980s. These methods substantially reduced the cost of polysilicon production from $200/kg in the 1980s to below $20/kg in the 2010s.

Key Milestones in Polysilicon Development

First Polysilicon Semiconductor

The late 1950s witnessed the development of the first semiconductor devices using polysilicon. The material’s excellent electrical properties, particularly its charge carrier mobility, made it ideal for transistors and diodes.

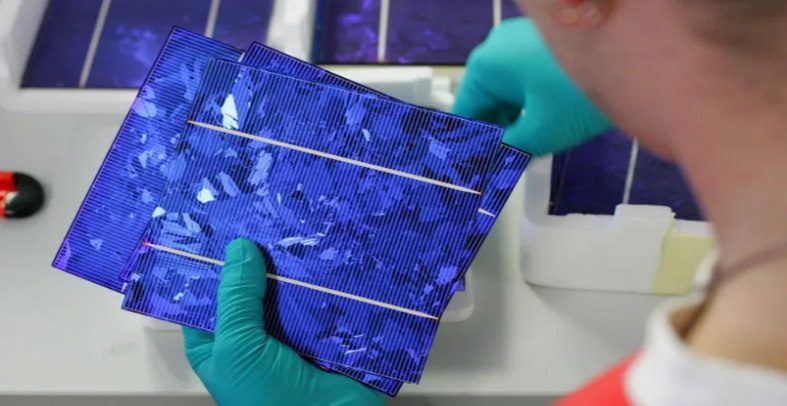

Polysilicon in Solar Cells

In 1981, the first solar cells utilizing polysilicon were introduced to the market. These cells boasted an efficiency of around 12%, a significant improvement over the previous generation’s 8%. This technological leap was a result of improvements in polysilicon’s quality and purity.

The Advent of Granular Polysilicon

The 2000s saw the development of granular polysilicon. This new form allowed for a more streamlined manufacturing process, cutting production time by up to 50% and reducing costs by 30%. Granular polysilicon also improved the efficiency of solar cells by minimizing material wastage.

The Efficiency Race

The race for higher efficiency in solar cells intensified in the 2010s. New techniques were continually developed to improve the quality and purity of polysilicon. As a result, by 2020, top-tier solar panels using monocrystalline silicon reached efficiencies close to 24%.

Market Dynamics and Pricing

The demand-supply dynamics of the polysilicon market has been a roller-coaster ride. In 2008, a shortage in polysilicon led to prices skyrocketing to over $400/kg. However, massive investments in production capacities, especially in China, led to an oversupply by 2012, causing prices to plummet to as low as $15/kg.

In this historical context, understanding the evolution of the polysilicon market offers valuable insights into its future potential and the challenges it might face.

Historical Market Overview

Evolution of the Polysilicon Market

Polysilicon’s Initial Introduction

Polysilicon, also known as polycrystalline silicon, was first introduced in the early 1950s as a primary material for the burgeoning semiconductor industry. By the 1980s, its importance had skyrocketed, mainly driven by the rapid growth of the electronics sector.

The Shift to Renewable Energy

Tongwei thinks,In the 1990s and 2000s, the demand for polysilicon took another leap with the rise of the solar photovoltaic (PV) industry. As solar panels became more popular and countries started investing in renewable energy, the need for high-quality polysilicon surged. By 2008, solar applications consumed approximately 90% of the global polysilicon supply.

Technological Advancements in Production

Advanced manufacturing methods, such as the Siemens process and fluidized bed reactor, were developed in the 1970s and 1980s. These methods substantially reduced the cost of polysilicon production from $200/kg in the 1980s to below $20/kg in the 2010s.

Key Milestones in Polysilicon Development

First Polysilicon Semiconductor

The late 1950s witnessed the development of the first semiconductor devices using polysilicon. The material’s excellent electrical properties, particularly its charge carrier mobility, made it ideal for transistors and diodes.

Polysilicon in Solar Cells

In 1981, the first solar cells utilizing polysilicon were introduced to the market. These cells boasted an efficiency of around 12%, a significant improvement over the previous generation’s 8%. This technological leap was a result of improvements in polysilicon’s quality and purity.

The Advent of Granular Polysilicon

The 2000s saw the development of granular polysilicon. This new form allowed for a more streamlined manufacturing process, cutting production time by up to 50% and reducing costs by 30%. Granular polysilicon also improved the efficiency of solar cells by minimizing material wastage.

The Efficiency Race

The race for higher efficiency in solar cells intensified in the 2010s. New techniques were continually developed to improve the quality and purity of polysilicon. As a result, by 2020, top-tier solar panels using monocrystalline silicon reached efficiencies close to 24%.

Market Dynamics and Pricing

The demand-supply dynamics of the polysilicon market has been a roller-coaster ride. In 2008, a shortage in polysilicon led to prices skyrocketing to over $400/kg. However, massive investments in production capacities, especially in China, led to an oversupply by 2012, causing prices to plummet to as low as $15/kg.

In this historical context, understanding the evolution of the polysilicon market offers valuable insights into its future potential and the challenges it might face.

Demand Drivers

Growth in the Solar Energy Sector

The Rise of Solar Installations

The past two decades have seen an exponential rise in solar installations worldwide. In 2020 alone, over 130 gigawatts (GW) of solar capacity got added globally, marking a 12% increase from the previous year. This surge in installations directly correlates with the escalating demand for polysilicon, given its critical role in solar panel manufacturing.

Cost Competitiveness of Solar Power

Solar power has reached grid parity in many regions, making it as cheap, if not cheaper, than conventional electricity sources. The average global cost for solar power stood at $0.04 per kilowatt-hour (kWh) in 2022, down from $0.15 per kWh in 2010. This cost competitiveness has spurred governments and private entities to ramp up their solar investments, driving demand for polysilicon even further.

Technological Advancements

Innovations in solar technology have led to panels with improved efficiency rates. The latest solar panels, with efficiencies hovering around 24%, rely heavily on high-quality polysilicon to achieve these numbers.

Expansion of the Semiconductor Industry

Growth in Electronics Consumption

The global consumption of electronic goods, from smartphones to laptops, has seen a steady rise. With over 1.5 billion smartphones sold annually as of 2022, the semiconductor industry, and by extension, the demand for polysilicon, is booming.

The Internet of Things (IoT) Revolution

The IoT market, which encompasses connected devices from smart refrigerators to wearable tech, is expected to reach 30 billion devices by 2025. Each of these devices requires semiconductors, further propelling the demand for polysilicon.

Emerging Applications of Polysilicon

Polysilicon in Batteries

With the electric vehicle (EV) market set to grow at an annual rate of 21% until 2030, there’s a push for more efficient batteries. Recent research has shown that polysilicon anodes in lithium-ion batteries can increase their capacity and lifespan, creating a new demand avenue for polysilicon.

Medical and Health Applications

Polysilicon has found novel applications in the medical sector, especially in sensors and diagnostic equipment. These devices, which ensure precision and accuracy, rely on the unique electrical properties of polysilicon.

Aerospace and Defense

The aerospace and defense sectors are continually looking for materials that are lightweight, durable, and efficient. Polysilicon, with its combination of these properties, has been finding increased applications in these sectors, from satellite components to advanced communication systems.

In conclusion, the demand drivers for polysilicon are vast and varied, spanning from the ubiquitous solar panels to niche aerospace applications. With technology’s relentless march forward, the relevance and demand for polysilicon are set to only increase.

Challenges in the Polysilicon Market

Environmental Concerns

Water Usage in Production

The production of polysilicon is water-intensive. A single ton of polysilicon can require up to 2,000 tons of water during its production process. In areas facing water scarcity, this level of consumption can strain local resources and raise sustainability concerns.

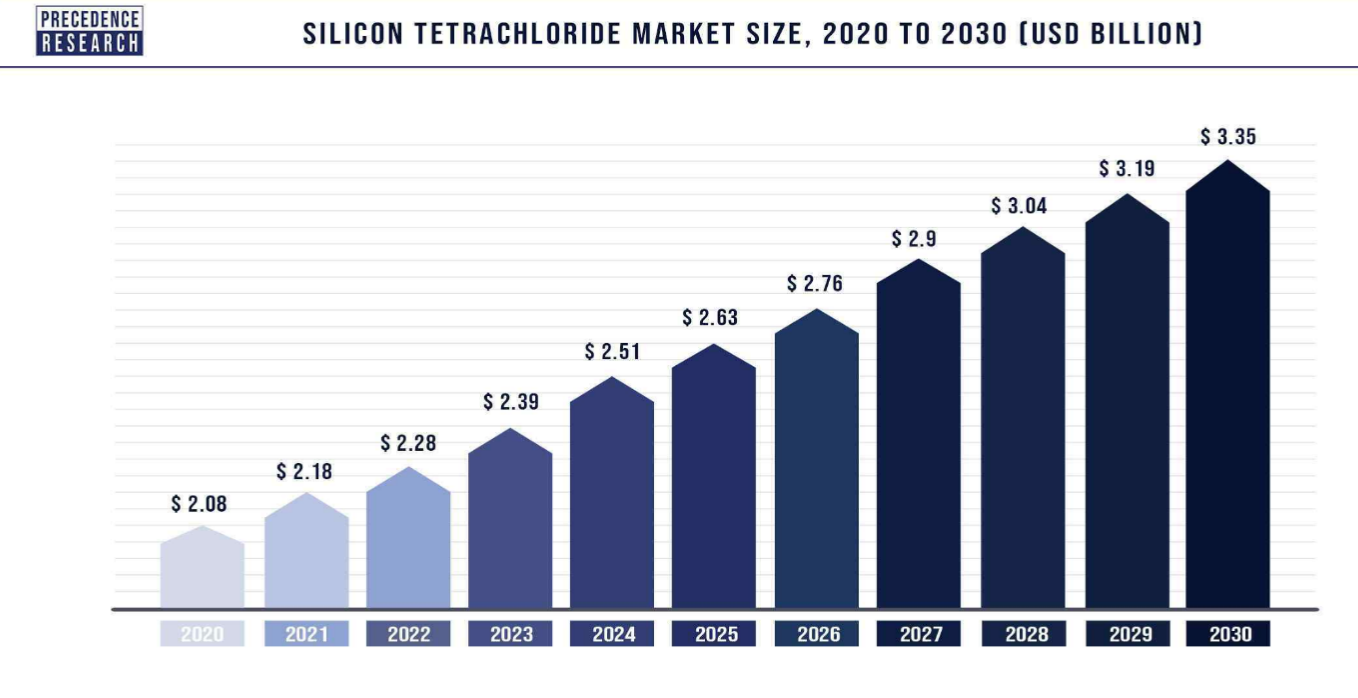

Waste and By-products

The production of polysilicon generates several by-products, including silicon tetrachloride. If not properly managed, this by-product can pose environmental risks. For instance, when exposed to moisture, silicon tetrachloride releases hydrochloric acid, which can harm aquatic life and the wider environment.

Energy Consumption

Polysilicon manufacturing is an energy-intensive process. The Siemens method, a popular technique for producing polysilicon, can consume up to 100 kWh of electricity for every kilogram of polysilicon produced. As a comparison, this is the average amount of energy an American household uses in three days. Given the increasing pressure to reduce carbon footprints, this high energy consumption becomes a significant concern.

Technological Barriers

Purity Standards

Achieving the high purity levels required for semiconductor applications — often 99.9999% pure or even higher — remains a technological challenge. Any slight impurity can affect the efficiency of solar cells or the performance of semiconductors.

Production Limitations

While there are advanced production techniques like the Siemens process, they come with their own set of challenges, from high costs to scalability issues. Meeting the increasing demand without compromising on quality becomes a significant hurdle.

Research and Development Lag

The time and investment required for research and development in the polysilicon industry can be considerable. With the rapid evolution of technologies in the solar and semiconductor sectors, staying ahead or even just keeping up becomes a challenge.

Market Competition and Consolidation

Intense Price Wars

The polysilicon market has seen fierce price wars, especially with the entry of several producers from China. This intense competition has, at times, led to a significant drop in prices, sometimes even below production costs, threatening the sustainability of producers.

Consolidation of Producers

As a response to the competitive pressures, there’s been a trend of consolidation in the market. Larger players with deeper pockets are acquiring or merging with smaller entities, leading to reduced diversity in the market. This consolidation can stifle innovation and reduce choices for consumers.

Dependency on Few Regions

While Asia, particularly China, dominates polysilicon production, this geographic concentration can pose risks. Any policy changes, environmental issues, or other disruptions in these regions can have a global ripple effect on polysilicon availability and prices.

In wrapping up, while the polysilicon market holds immense potential, navigating its challenges requires foresight, innovation, and adaptability. Balancing environmental concerns, technological advancements, and market dynamics will be crucial for stakeholders in the coming years.

Future Outlook and Predictions

Projected Demand and Supply Dynamics

Skyrocketing Demand in Solar and Tech Industries

With global initiatives pushing for greener energy solutions, the solar industry is projected to grow by 15% annually over the next decade. By 2035, the demand for polysilicon from the solar sector alone is expected to reach 700,000 metric tons per annum, a jump from the current 450,000 metric tons. This increase in demand might strain the existing supply chain.

Production Capacity Expansion

Given the anticipated demand surge, several major producers, particularly in Asia, are ramping up their production capacities. It’s projected that by 2030, the global polysilicon production capacity will reach 1 million metric tons, up from the 600,000 metric tons in 2022. This expansion, however, will require significant investments and time, leading to potential short-term supply crunches.

Price Fluctuations

The interplay of increasing demand and challenges in rapidly scaling up production will likely result in price fluctuations. While the long-term trend might be towards price stabilization due to economies of scale, short-term spikes are anticipated, especially around 2025 when demand is set to outpace supply significantly.

Potential Breakthroughs in Polysilicon Technology

Greener Production Methods

With increasing scrutiny on the environmental footprint of industries, research is ongoing to find more sustainable methods of polysilicon production. Breakthroughs in this area can reduce the energy and water footprint of the current processes, driving down both costs and environmental impacts.

Enhanced Purity Levels

R&D efforts are aiming to achieve even higher purity levels without a proportional rise in production costs. Success in this domain will mean more efficient solar cells and advanced semiconductors, unlocking new applications and markets.

Modular and Scalable Production Units

The future might see the rise of modular polysilicon production units that are more scalable and adaptable than the current mega-factories. This flexibility can allow producers to quickly ramp up or scale down production based on demand, leading to more stable prices and supply.

Geopolitical Factors Affecting the Market

Trade Wars and Tariffs

Recent years have witnessed trade tensions, particularly between the US and China. Any escalation or introduction of tariffs on polysilicon or its end products can disrupt the global supply chain, leading to price volatilities.

Regional Production Dominance

Asia’s dominance in polysilicon production, especially China, means any significant policy shift, environmental regulation, or geopolitical event in the region has global repercussions. Diversifying production bases across continents can be a strategic move to mitigate these risks.

Sustainability and Regulatory Pressures

Countries are increasingly focusing on sustainable production methods. Any stringent regulations on water use, waste disposal, or energy consumption can push producers to adopt new technologies faster, potentially leading to short-term supply disruptions but long-term industry benefits.

In essence, the future of the polysilicon market is bright but not without its set of challenges. Strategic foresight, adaptability, and a keen understanding of the geopolitical landscape will be essential for stakeholders to navigate this dynamic market.

Impact of External Factors

Influence of Global Economic Trends

Economic Booms and Busts

Historically, periods of robust global economic growth have directly influenced increased demand for electronics and energy, both of which rely on polysilicon. For example, during the tech boom of the early 2000s, there was a surge in demand for semiconductors, driving polysilicon prices upward. Conversely, during economic downturns, reduced consumer spending can lead to diminished demand for electronics, putting downward pressure on polysilicon prices.

Emerging Markets

As emerging economies like India, Brazil, and several African nations continue to industrialize and urbanize, their demand for electronics and renewable energy solutions is set to rise. This growth will indirectly boost the polysilicon market. For instance, India’s ambitious goal to achieve 450 GW of renewable energy capacity by 2030 implies a direct surge in demand for solar panels and, subsequently, polysilicon.

Currency Fluctuations

Exchange rate dynamics, particularly involving the US dollar, Euro, and Chinese Yuan, can influence the global trade of polysilicon. A stronger dollar can make imports cheaper for countries, potentially boosting demand, while a weaker dollar can make exports more competitive, benefitting US-based polysilicon producers.

Regulatory and Policy Changes

Environmental Legislations

Stringent environmental regulations can force polysilicon manufacturers to adopt cleaner, but potentially more expensive, production methods. For instance, in the European Union, regulations like the REACH directive might influence how polysilicon is produced and traded.

Import-Export Tariffs

Policies that impose tariffs on imported polysilicon, like the ones previously implemented between the US and China, can drastically affect trade dynamics, leading to shifts in production bases and potential price hikes for end consumers.

Subsidies and Incentives

Government incentives promoting the solar industry, like tax breaks or subsidies, can accelerate the adoption of solar panels, creating a direct spike in polysilicon demand. For example, Germany’s Erneuerbare-Energien-Gesetz (EEG) policy in the early 2000s led to a rapid expansion of the country’s solar industry, driving up global polysilicon demand.

Impact of Renewable Energy Goals on Polysilicon Demand

Global Climate Agreements

Major global agreements, like the Paris Agreement, aim to limit global warming by reducing carbon emissions. Such initiatives indirectly boost the demand for renewable energy sources like solar power, subsequently pushing the demand for polysilicon higher.

National Renewable Targets

Several countries have set explicit renewable energy targets. For instance, China aims to achieve 50% renewable energy consumption by 2050. Achieving these targets will require significant expansions in solar infrastructure, leading to a consistent rise in polysilicon demand.

Technological Advancements in Solar Efficiency

As research continues to improve the efficiency of solar cells, newer generations of solar panels might require lesser quantities of polysilicon without compromising on power output. This evolution, while beneficial for solar adoption, can influence the quantity dynamics of polysilicon demand.

In conclusion, while the intrinsic properties and applications of polysilicon play a significant role in its market dynamics, a myriad of external economic, regulatory, and industry-specific factors equally influence its global demand and supply scenarios.