The clutch is a mechanical device in cars that engages and disengages power transmission, especially between driving shafts.

Introduction

In the realm of automobiles, understanding the intricacies of how they function can offer valuable insights for both drivers and enthusiasts. Central to the drivetrain’s performance is a crucial component known as the clutch. While often overlooked, the clutch plays a significant role in ensuring smooth transitions between gears, ultimately optimizing power transfer and fuel efficiency. This section provides an in-depth look at the clutch, from its basic definition to its primary function within a car’s drivetrain.

Basic Definition of a Clutch

The clutch, at its core, is a mechanical device used to engage and disengage the power transmission, especially from a driving shaft to a driven shaft. In cars, it specifically connects the engine to the transmission, allowing the vehicle to smoothly change gears. Clutches are essential in vehicles with manual transmissions but are also present in various forms in many automatic transmission vehicles. For a deep dive into the intricacies of clutches, Wikipedia provides a comprehensive overview.

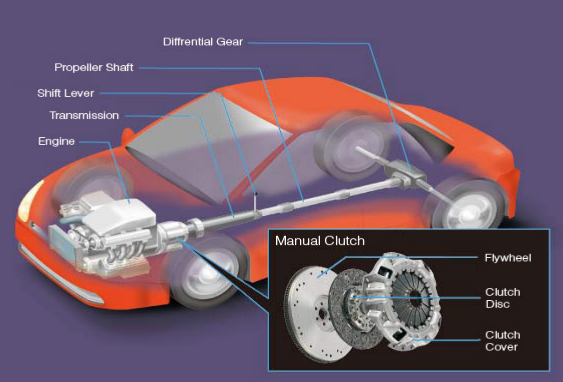

The Role of the Clutch in a Car’s Drivetrain

A car’s drivetrain, also known as the powertrain, includes the engine, transmission, driveshafts, axles, and wheels. The clutch’s primary role within this system is to transmit torque from the engine to the transmission, allowing for changes in gear ratios. Without a clutch, the car would jerk or stall when changing gears.

- Power Transfer: The clutch ensures that there’s a seamless transfer of power from the engine to the wheels. For instance, when a car accelerates from 0 to 60 mph in 6 seconds, the clutch manages power delivery during each gear change, ensuring consistent acceleration.

- Protection: By allowing for a controlled slippage, the clutch prevents potential damage to the engine and gearbox. For instance, if a car’s engine operates at an average speed of 2,000 RPM, and a sudden change in gears happens, the clutch aids in ensuring the engine doesn’t get damaged due to a drastic change in rotational speeds.

- Fuel Efficiency: The clutch plays a vital role in ensuring fuel efficiency. Imagine a car that achieves an average of 30 miles per gallon. Without an efficient clutch system, this mileage could drop by as much as 10% due to the inefficient transfer of power.

To further understand the value, efficiency, and cost implications of a clutch, one must consider these roles in tandem with other drivetrain components. Knowing the specific parameters and specifications of a clutch can help in assessing its quality, potential lifespan, and overall efficiency in a car’s operation.

Components of a Clutch System

Understanding the clutch system involves breaking it down to its fundamental components. Each part is crucial and works in harmony to ensure a seamless and efficient operation. Let’s delve into the main components that make up a clutch system and understand their role, specifications, and significance in the operation.

The Clutch Disc

The clutch disc is the heart of the clutch system. Sandwiched between the engine’s flywheel and the transmission’s pressure plate, it ensures power transfer from the engine to the transmission. Made of a high-friction material, it grips onto the flywheel and pressure plate to enable power transfer.

- Material: The clutch disc is typically made of organic or ceramic materials, known for their durability and high-coefficient of friction. Ceramic materials can handle higher temperatures, but organic materials are known for smoother engagement.

- Size: The diameter of a typical clutch disc can range from 8.5 inches to 11 inches, depending on the vehicle type and purpose.

- Life Span: With regular usage and proper driving habits, a clutch disc can last anywhere between 50,000 to 100,000 miles. Aggressive driving can significantly reduce this lifespan.

- Cost: A replacement clutch disc can range from $50 to $300, depending on the brand and material. Here is a comprehensive overview of different clutch discs.

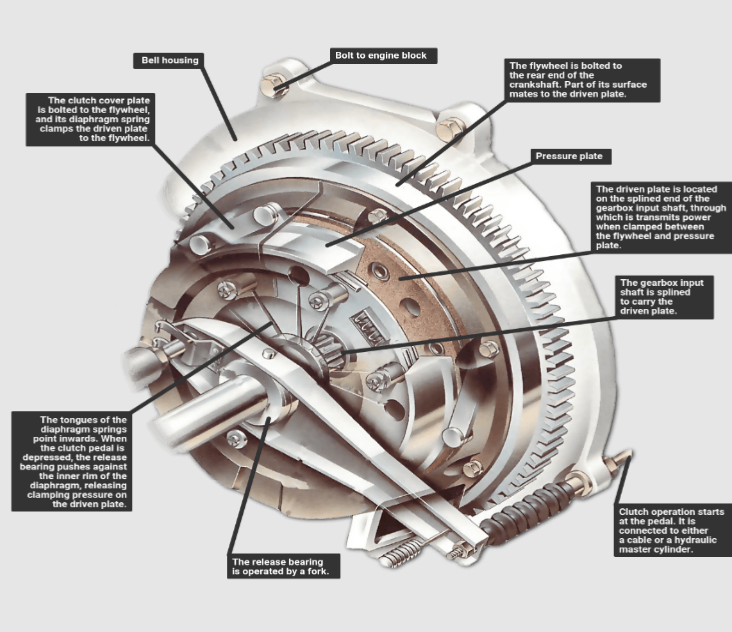

The Pressure Plate

The pressure plate is responsible for engaging and disengaging the clutch disc from the flywheel. It applies force on the clutch disc, pressing it against the flywheel.

- Mechanism: A spring mechanism is used to apply pressure, with a diaphragm-style being the most common.

- Material: Typically made of durable metal to withstand the pressures and heat associated with regular use.

- Life Span: The pressure plate’s lifespan is comparable to that of the clutch disc, ranging from 50,000 to 100,000 miles, based on driving habits.

The Flywheel

The flywheel connects directly to the engine and helps in maintaining engine speed by storing rotational energy. It provides a smooth surface for the clutch disc to grip onto.

- Material: Made of either cast iron or steel, known for their durability and ability to dissipate heat.

- Weight: A typical flywheel can weigh between 15 to 30 pounds, with performance variants being on the lighter end for faster engine response.

- Life Span: With proper maintenance, a flywheel can last upwards of 150,000 miles, though it might need resurfacing after every clutch replacement.

Release (Throw-out) Bearing

This component plays the role of disengaging the clutch when the pedal is pressed. It pushes against the pressure plate’s diaphragm fingers, releasing the clutch disc from the flywheel.

- Material: Typically made of high-quality steel, ensuring a long service life.

- Life Span: The release bearing can last anywhere between 40,000 to 70,000 miles, though it’s recommended to replace it with every clutch replacement.

Clutch Master and Slave Cylinders

These hydraulic components work in tandem to transfer the force from the clutch pedal to the release bearing.

- Operation: When the clutch pedal is pressed, the master cylinder pushes hydraulic fluid to the slave cylinder, which in turn pushes the release bearing.

- Material: Both cylinders are generally made of durable metals like aluminum or steel.

- Life Span: With proper maintenance, these cylinders can last up to 100,000 miles. However, any signs of fluid leakage or a spongy clutch pedal might indicate a problem.

For those interested in a deeper understanding of the clutch’s components, especially regarding their quality and materials used, the Wikipedia page on clutches is a valuable resource.

How a Clutch Works

The clutch is an ingenious mechanism that lies at the intersection of a vehicle’s engine and its transmission. While its components might seem complex at first glance, its primary function revolves around the concepts of engagement and disengagement, heavily relying on friction. To grasp the workings of a clutch, one needs to comprehend these foundational concepts.

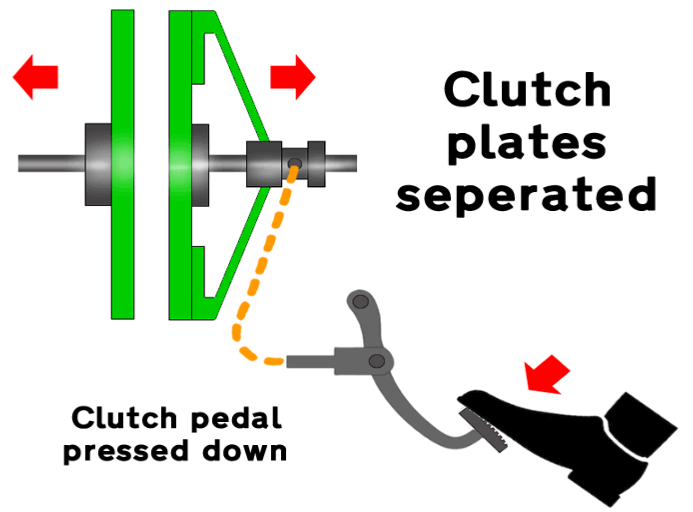

Engaging and Disengaging Process

When you press the clutch pedal, you initiate a sequence of events leading to the disconnection of the engine from the transmission. Conversely, releasing the pedal leads to their reconnection. Let’s break down this process:

- Pedal Pressed (Disengaging):

- As the pedal is pressed, hydraulic fluid is pushed from the clutch master cylinder to the slave cylinder. This movement activates the release bearing, pressing it against the diaphragm spring of the pressure plate.

- With this pressure exerted on the diaphragm, the pressure plate is pulled away from the clutch disc. This action disconnects the engine’s rotational force from the transmission, allowing the driver to change gears.

- Pedal Released (Engaging):

- Releasing the pedal does the opposite. The release bearing moves away from the diaphragm spring, causing the spring to push the pressure plate against the clutch disc.

- This action binds the clutch disc between the flywheel and the pressure plate, linking the engine’s power to the transmission. The vehicle can then transmit power to the wheels and move.

The entire process relies heavily on precision, and even a delay of a few milliseconds can make the difference between a smooth gear shift and a jarring one.

Role of Friction in Clutch Operation

Friction is the unsung hero in the clutch system. Without it, the transfer of power from the engine to the transmission would be impossible. Here’s how friction plays its role:

- Gripping Power:

- The clutch disc, made of high-friction materials, is sandwiched between the flywheel and the pressure plate. As the pressure plate pushes against the clutch disc, it binds the disc to the spinning flywheel. This grip, thanks to friction, allows power to be transmitted to the transmission.

- Smooth Transition:

- The quality of the materials in the clutch disc can impact the smoothness of gear transitions. High-quality materials provide consistent friction levels, even under varying temperatures and conditions. For instance, a clutch disc with a diameter of 10 inches, using premium organic materials, might offer smoother transitions and last longer than a lower-quality counterpart.

- Wear and Tear:

- Over time, the friction material on the clutch disc wears down due to continuous engagement and disengagement. This wear can affect the efficiency and grip of the clutch system. For example, a clutch that used to engage smoothly at a pedal height of 5 inches might start to engage only at 3 inches after 60,000 miles due to wear.

- Heat Dissipation:

- Friction produces heat, and managing this heat is crucial. The flywheel, typically made of cast iron or steel, acts as a heat sink, absorbing and dissipating the heat generated during clutch operation. If not managed properly, excessive heat can reduce the lifespan of the clutch system.

To delve deeper into the physics behind friction and its pivotal role in various mechanisms, including the clutch, one can refer to the Wikipedia page on Friction. Knowing the intricacies of friction can provide insights into the efficiency, lifespan, and overall quality of a clutch system.

Types of Clutches

In the vast world of automobiles and machinery, the clutch serves as a pivotal component in power transfer. While the foundational principle remains consistent, various applications and requirements have given rise to diverse types of clutches. From the basic single plate clutch in everyday cars to the centrifugal clutch found in some mopeds and chainsaws, each type serves a distinct purpose based on its design, advantages, and operation.

Single Plate Clutch

As the name suggests, the single plate clutch utilizes one clutch disc sandwiched between the engine’s flywheel and the pressure plate.

- Construction: A singular disc, often made of organic material, which provides the necessary friction to engage and disengage the clutch.

- Usage: Commonly found in most passenger cars due to its simplicity and cost-effectiveness.

- Advantages: Simple design, easy maintenance, and cost-effective. A quality single plate clutch might cost between $70 to $200 depending on the vehicle and brand.

- Drawbacks: May not handle very high torques as efficiently as multi-plate clutches.

For more insights on the single plate clutch, here’s a detailed Wikipedia article.

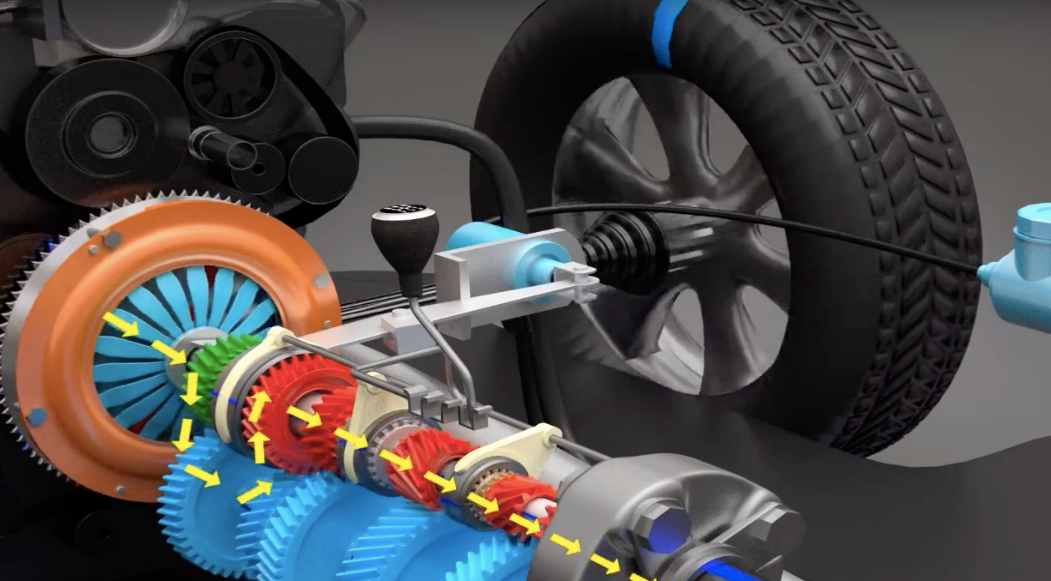

Multi-Plate Clutch

This type utilizes multiple discs to engage and disengage the clutch, providing a greater surface area without increasing the clutch’s overall size.

- Construction: Multiple clutch discs stacked together. This design allows for more frictional surface area in a compact space.

- Usage: Often seen in racing cars, motorcycles, and heavy-duty vehicles where high torque handling is essential.

- Advantages: Can handle higher torques, provides smoother transitions due to multiple friction surfaces, and offers a compact design. Depending on the application, these clutches might be priced from $250 to $1000.

- Drawbacks: More complex than single plate variants and might require more frequent maintenance due to multiple components.

Cone Clutch

The cone clutch has a conical shape and utilizes the friction between two conical surfaces to engage and disengage.

- Construction: One conical-shaped disc that fits into a conical housing. The frictional engagement happens on the conical surfaces.

- Usage: Less common in modern vehicles but can be found in some older cars or specific industrial applications.

- Advantages: Offers smooth engagement due to the increased surface contact as the conical surfaces mesh.

- Drawbacks: Wear can lead to decreased efficiency over time, and it might be harder to find replacements due to its less frequent usage today. A cone clutch might be priced around $300 to $600 based on rarity and application.

Centrifugal Clutch

This clutch operates on the principle of centrifugal force. As the engine speed increases, centrifugal forces push the clutch plates outward, engaging the clutch.

- Construction: Comprises of clutch shoes that are thrown outward by centrifugal force as RPM increases.

- Usage: Common in mopeds, go-karts, chainsaws, and some small motorcycles.

- Advantages: Automatic engagement and disengagement based on engine speed, making it simpler for users as no clutch operation is required. These clutches might cost anywhere between $40 to $150 depending on size and application.

- Drawbacks: Not suitable for applications requiring precise clutch control, as engagement is purely based on RPM.

The Wikipedia page on clutches provides a broader overview of these types and others, helping one understand their unique applications and intricacies.

Common Clutch Problems and Maintenance

The clutch, being a pivotal component in the powertrain, undergoes significant wear and tear. As with all machinery, wear, and repeated use can lead to issues. Recognizing common clutch problems early on and ensuring proper maintenance can save significant time and money in the long run, ensuring a longer lifespan and efficient performance.

Slipping Clutch

One of the most common issues faced by drivers is a slipping clutch.

- Symptoms: The engine revs increase, but there’s no proportional increase in the vehicle’s speed. In severe cases, there might be a burning smell due to excessive friction.

- Causes: Over time, the friction material on the clutch disc can wear out, reducing its grip. Oil contamination, a warped pressure plate, or damaged clutch springs can also lead to slippage.

- Solution: In most cases, replacing the worn-out clutch components can resolve the issue. The average cost for clutch replacement can range from $500 to $1200, including parts and labor.

Hard Clutch

A hard clutch requires excessive force to depress, making gear shifts strenuous.

- Symptoms: The clutch pedal feels stiff and harder to press down than usual.

- Causes: This can be due to a problem with the clutch cable, hydraulic issues, or a malfunction in the linkage.

- Solution: Lubricating the clutch cable or replacing it, addressing any hydraulic system leaks, or adjusting the linkage can rectify the problem. Maintenance for such issues typically costs between $150 to $400 based on the specific problem and region.

Noisy Clutch

Noises are usually indicative of underlying problems, and the clutch is no exception.

- Symptoms: Unusual noises when the clutch engages or disengages.

- Causes: A worn-out release bearing, pilot bearing, or damaged input shaft can cause these noises.

- Solution: Replacing the noisy component is the best solution. Depending on the part and vehicle model, repairs might range from $300 to $800.

Maintenance Tips and Best Practices

Proper maintenance and practices can extend the lifespan of your clutch and ensure efficient operation.

- Regular Inspection: Regularly inspect the clutch system for wear, especially if you notice any symptoms of slipping or unusual noises.

- Avoid Riding the Clutch: Resting your foot on the clutch pedal, even lightly, can cause unnecessary wear. Always remove your foot from the pedal unless you’re actively using it.

- Use Quality Components: When replacing parts, always opt for high-quality components. A premium clutch disc might cost around $100 to $250 but offers better longevity and performance.

- Address Issues Promptly: If you notice any clutch problems, address them immediately. Delaying can lead to more extensive damages and higher repair costs.

- Professional Servicing: It’s always wise to have your clutch system checked by professionals during regular service intervals. They can spot issues that might escape the untrained eye.

For a comprehensive overview of clutch problems, diagnosis, and maintenance, consider visiting the Wikipedia page on clutches. Proper care and understanding of the clutch system can significantly extend its lifespan and ensure smooth vehicle operation.

Differences Between Manual and Automatic Transmission Clutches

The transmission in a vehicle is fundamental to its ability to move. Clutches play an essential role in both manual and automatic transmissions, though they function and appear differently. Understanding the distinctions between the two can provide better insights into their efficiencies, potential issues, and overall operations.

Torque Converter in Automatics

A torque converter is unique to automatic transmissions. It serves a purpose similar to a clutch but operates on a different principle.

- Functionality: Instead of directly linking the engine to the transmission with physical components, the torque converter uses fluid dynamics to transmit power. It allows the vehicle to stop in gear without stalling the engine.

- Components: A torque converter consists of an impeller (connected to the engine), a turbine (connected to the transmission), and a stator. Fluid circulates within this system, transferring power through fluid motion.

- Efficiency: Torque converters can multiply torque when the difference in rotation speed between the impeller and turbine is significant, improving off-the-line acceleration. However, at higher speeds, some torque converters can lock to improve fuel efficiency.

- Cost and Maintenance: Torque converters are generally more expensive than traditional clutches due to their complexity. The average cost for a torque converter replacement can range from $600 to $1000. Regular fluid checks and replacements are crucial for longevity. Refer to the Wikipedia page on torque converters for an in-depth exploration of their mechanics.

Traditional Clutches in Manuals

Manual transmissions rely on traditional clutches that offer a direct mechanical link between the engine and transmission.

- Functionality: The clutch in a manual transmission physically connects and disconnects the engine from the transmission. It requires driver input for gear changes.

- Components: This system primarily comprises a clutch disc, pressure plate, and flywheel. When the clutch pedal is pressed, it disengages the clutch disc from the flywheel, breaking the link between the engine and transmission.

- Efficiency: Manual transmissions tend to be more fuel-efficient at constant speeds due to the direct connection and lesser energy loss. However, their efficiency can vary based on the driver’s skill level.

- Cost and Maintenance: Traditional clutches are generally less expensive to replace than torque converters, with prices ranging from $500 to $1200, including parts and labor. The life span of a manual clutch is largely influenced by driving habits.

For a more exhaustive understanding of manual transmissions and clutches, the Wikipedia page on manual transmissions is a recommended resource.

In conclusion, while both systems aim to manage power delivery from the engine to the wheels, the mechanics behind manual and automatic transmission clutches differ significantly. Understanding these distinctions can aid in making informed decisions regarding vehicle selection, driving habits, and maintenance needs.

The Evolution of Clutches in Modern Cars

As automobiles evolved over time, the clutch system, a pivotal component in cars, also underwent significant advancements. Modern vehicles today benefit from technological enhancements and innovative designs that have optimized performance, driving comfort, and efficiency. These adaptations cater to the demands of the present-day driver, marrying the best of both manual and automatic transmission worlds.

Dual-Clutch Systems

Dual-clutch systems, often referred to as dual-clutch transmissions (DCT), are a revolutionary step in the evolution of car clutches.

- Functionality: Dual-clutch systems essentially have two separate clutches—one for odd-numbered gears and another for even-numbered ones. This setup ensures rapid gear shifts, eliminating the power loss usually associated with traditional manual gear changes.

- Components: Dual-clutch systems consist of two separate shafts: one for the main set of gears and another for the odd ones. These shafts allow for a preselected gear to be on standby, waiting for engagement.

- Efficiency: Dual-clutch systems combine the efficiency of manual transmissions with the convenience of automatic ones. The rapid gear shifts contribute to smoother acceleration and better fuel efficiency, with up to a 10% improvement compared to conventional systems.

- Cost and Maintenance: The average replacement cost for a DCT can range from $3,000 to $5,000, depending on the make and model. Regular fluid checks and replacements remain vital for longevity. For more in-depth knowledge, visit the Wikipedia page on dual-clutch transmissions.

Electronic and Automated Clutch Systems

The integration of electronics in clutch systems has paved the way for more intuitive, efficient, and responsive driving experiences.

- Functionality: Electronic and automated clutch systems remove the need for a clutch pedal altogether. Sensors and actuators manage the engagement and disengagement processes based on engine speed, throttle position, and other parameters.

- Components: These systems heavily rely on sensors, electronic control units (ECU), and actuators to manage the clutch operation. An electronic interface replaces the traditional manual link between the driver and the clutch.

- Efficiency: By automating the clutch operation, these systems ensure optimal gear engagement, thereby maximizing fuel efficiency and performance. Automated clutch systems can increase fuel efficiency by up to 12% compared to traditional setups.

- Cost and Maintenance: Electronic and automated clutch systems can be pricey due to their sophisticated components. Average costs for replacements can be upwards of $4,500. Maintenance typically involves software updates, sensor checks, and periodic actuator inspections. For a more comprehensive understanding, the Wikipedia page on automated manual transmission is an excellent resource.

In summary, modern cars benefit significantly from the advancements in clutch technology. Whether through dual-clutch systems or electronic interfaces, these improvements have made driving more efficient, comfortable, and enjoyable for the contemporary motorist.

Conclusion

The clutch system stands as a cornerstone in the domain of automotive engineering. From the early stages of the automobile era to today’s technologically advanced vehicles, the clutch’s role remains paramount. Its evolution mirrors the journey of innovation in the automobile industry, consistently improving in efficiency, reliability, and convenience.

The Importance of Understanding Your Car’s Clutch

Gaining insights into the clutch system of your vehicle isn’t just for mechanics or car enthusiasts. It’s for every driver who seeks to ensure their vehicle’s optimum performance and longevity.

- Safety: Recognizing the signs of a malfunctioning clutch can prevent potential accidents on the road. By being proactive in addressing clutch issues, drivers can ensure safer rides for themselves and others.

- Cost-Efficiency: Being in tune with the state of your clutch helps in anticipating possible replacements or repairs. Early detection of issues can save considerable costs, with average clutch replacement expenses ranging between $1,200 to $1,400.

- Optimal Performance: A well-maintained clutch translates to smoother gear transitions, better fuel efficiency, and an overall enhanced driving experience. By understanding the nuances of their car’s clutch, drivers can reap these benefits more consistently.

For those eager to delve deeper, the Wikipedia page on clutches offers extensive information on the topic.

The Future of Clutch Technology

As with many aspects of automotive technology, the clutch system is on the cusp of even more groundbreaking innovations.

- Integration with AI: Future clutches might seamlessly integrate with artificial intelligence systems. These AI-driven clutches would autonomously adjust to driving conditions, offering unmatched efficiency and performance.

- Material Advancements: Clutch components could soon utilize more advanced materials, increasing durability and reducing wear. Materials such as carbon composites promise a potential lifespan increase of 15% for clutches.

- Green Evolution: As the world gravitates towards eco-friendly solutions, clutches will play a role in enhancing the fuel efficiency and eco-friendliness of vehicles. Potential improvements could lead to a 10% reduction in carbon emissions from vehicles.

To glimpse what’s on the horizon for clutch systems, the Wikipedia page on future automotive technologies can be an insightful read.

In wrapping up, the clutch remains an intricate and essential part of any vehicle. Understanding its nuances and keeping abreast of technological advancements not only augments the driving experience but also showcases the fascinating journey of innovation in the automotive world.