A Hydraulic pump is a vital component in numerous systems and industries. It is a mechanical device that converts mechanical power into hydraulic energy, thus creating a force that drives various types of machinery.

Introduction

Definition of a Hydraulic Pump

A Hydraulic Pump is a mechanical device that converts mechanical energy into hydraulic energy or fluid power. It functions by creating a vacuum at the pump inlet, forcing fluid from the reservoir into the inlet line, and then pushing the fluid to the pump outlet, delivering it to the hydraulic system.

Brief History of Hydraulic Pumps

The basic concept of the hydraulic pump dates back to ancient times, but the actual use of hydraulic power became widespread in the late 19th and early 20th centuries, with the advent of the industrial revolution. Hydraulic pumps have since evolved and become more efficient and reliable, finding wide-ranging applications in many industries.

Types of Hydraulic Pumps

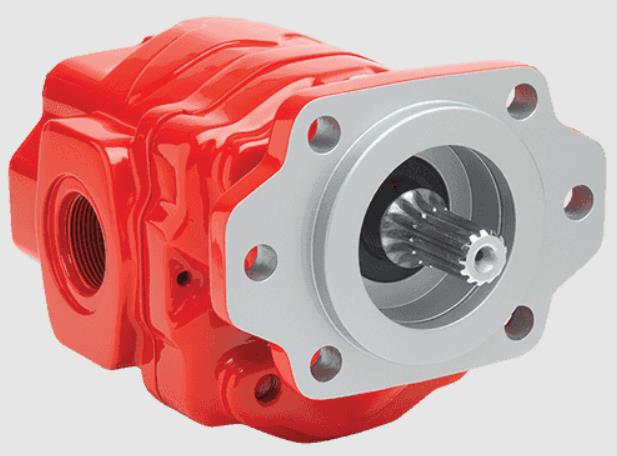

Gear Pumps

Gear Pumps, a type of hydraulic pump, stand out with their simple design and operation. These pumps have two meshing gears. The drive shaft powers one of these gears. When the gears rotate, they create a vacuum that pulls fluid into the pump. The gears trap this fluid in the spaces between their teeth and then push it out on the other side of the pump.

Piston Pumps

Piston Pumps are another type of hydraulic pump. They operate via multiple piston cylinders arranged in a circular configuration within the pump housing. As the drive shaft rotates, it causes the pistons to move back and forth. This movement draws in and expels the hydraulic fluid, creating fluid power. Piston pumps are known for their excellent performance under high pressure.

Vane Pumps

Vane Pumps are a type of hydraulic pump that utilizes the back-and-forth movement of rectangle-shaped vanes inside slots to generate hydraulic power. These pumps are known for their quiet operation, making them suitable for environments where noise reduction is important.

The Working Principle of Hydraulic Pumps

Basic Mechanism of Operation

The basic operation of a Hydraulic Pump revolves around the principle of displacement. It creates a vacuum at the pump inlet using mechanical action, drawing fluid from the reservoir. The pump then transports this fluid to the outlet and into the hydraulic system, thus converting mechanical power into hydraulic power.

How Different Types of Pumps Work

- Gear Pumps work by utilizing two interlocking gears. One gear is driven by the power source, and it interlocks with the other gear to transport fluid.

- Piston Pumps operate using multiple pistons in a circular array within the pump housing. The pistons move back and forth due to the rotation of the drive shaft, causing the intake and discharge of fluid.

- Vane Pumps feature rectangular vanes in slots that move back and forth, pushing the fluid out of the pump.

Applications of Hydraulic Pumps

Industrial Applications

Hydraulic pumps find wide use in various industrial applications. They are essential in machinery used for production, assembly, and lifting heavy loads.

| Industrial Area | Use of Hydraulic Pumps |

|---|---|

| Manufacturing | For operating heavy machinery |

| Material Handling | In forklifts, stackers |

| Power Generation | Control systems in wind turbines, hydroelectric stations |

Automotive Applications

In the automotive industry, hydraulic pumps are integral to many systems including power steering, transmission, and brake systems. They facilitate the smooth operation of these critical systems.

Construction Equipment Applications

Construction machinery such as excavators, loaders, and cranes heavily rely on hydraulic pumps. They offer the required power to operate these heavy-duty machines efficiently.

Agricultural Applications

Agricultural machinery like tractors, harvesters, and loaders also utilize hydraulic pumps. They are integral to the operation of attachments like loaders and cultivators, providing the necessary hydraulic power for efficient functioning.

Advantages and Disadvantages of Hydraulic Pumps

Advantages

Hydraulic pumps, such as those produced by Rotontek, offer several advantages:

- Powerful Performance: Hydraulic pumps can generate a significant amount of power, relative to their size.

- Versatility: They can be used in a wide range of applications, from automotive systems to heavy-duty industrial machinery.

- Control Flexibility: The power output of a hydraulic pump can be easily adjusted by controlling the amount of fluid that it moves.

Disadvantages

However, there are also some disadvantages associated with hydraulic pumps:

- Maintenance Requirements: Hydraulic pumps require regular maintenance to ensure their optimal operation.

- Potential for Leaks: If the system’s seals or valves are compromised, hydraulic fluid can leak, leading to loss of power and possible damage to the environment.

- Noise and Heat Generation: Hydraulic pumps may produce a significant amount of noise and heat. Proper management of these factors is crucial for safe and comfortable operation.

Maintenance and Troubleshooting of Hydraulic Pumps

Common Issues and Solutions

Hydraulic pumps can encounter several common issues. These include fluid contamination, air and water ingress, and issues related to overheating. Companies like Rotontek often provide guidelines for troubleshooting these common problems.

Maintenance Best Practices

Proper maintenance of hydraulic pumps is crucial to ensure their longevity and optimal performance. This includes regular checks for leaks, monitoring the temperature and noise levels, ensuring proper fluid levels, and periodically replacing the hydraulic fluid. Rotontek, for instance, provides comprehensive maintenance guides for their hydraulic pumps, helping users to maximize their performance and lifespan.

Innovations and Future Trends in Hydraulic Pump Technology

Latest Innovations

Over the years, hydraulic pump technology has seen several advancements. For instance, companies like Rotontek are developing more energy-efficient hydraulic pumps that also reduce noise levels. Smart pump technology, which includes sensors and advanced monitoring capabilities, is also becoming more prevalent, enabling predictive maintenance and enhancing system reliability.

Future Trends

Looking towards the future, we can expect to see further integration of digital technologies within hydraulic pump systems. The rise of the Internet of Things (IoT) and AI could potentially lead to more intelligent and self-regulating hydraulic systems. Additionally, improvements in the materials and designs used for hydraulic pumps are likely to further enhance their efficiency and longevity.

Conclusion

Summary of Key Points

In this article, we’ve delved into the topic of hydraulic pumps, examined how they work, discussed their different types, and outlined their various applications. We’ve also examined the advantages and disadvantages of hydraulic pumps, how to maintain and troubleshoot them, as well as the latest innovations and future trends in hydraulic pump technology.

The Importance of Hydraulic Pumps in Modern Society

Hydraulic pumps play a crucial role in our modern society. They power a wide array of machinery and systems, from cars to industrial machinery, and even power generation plants. As technology advances, it’s clear that hydraulic pumps will continue to evolve, enhancing efficiency and sustainability while expanding their range of applications.