CVT Transmission is a continuous variable transmission offering seamless gear ratios for smoother acceleration.

Introduction

The transmission, an essential component in vehicles, serves as the gateway to understand the efficiency, speed, and overall performance of automobiles. Often, people overlook the importance of a transmission, focusing more on the engine’s power or the aesthetics of the vehicle. However, without an efficient transmission, even a powerful engine might not translate to an optimal driving experience.

Brief Overview of Transmissions

A transmission is a mechanism that transmits power from the engine to the wheels, allowing the vehicle to move. A manual transmission requires drivers to shift gears manually using a clutch. On the other hand, an automatic transmission, which includes the CVT, does this shifting automatically, based on specific parameters such as vehicle speed and engine load.

Key aspects to consider when looking at transmissions:

- Power: Transmissions handle varying amounts of power. For example, a sedan might have a transmission that handles around 150 to 250 horsepower, while a sports car’s transmission can manage over 700 horsepower.

- Size and Specifications: A transmission’s size is often influenced by its design and the vehicle it serves. An average passenger car transmission is considerably smaller and lighter than those used in heavy-duty trucks.

- Efficiency: An efficient transmission can lead to better fuel economy. For instance, a well-designed automatic transmission might offer a 5-10% improvement in fuel efficiency compared to a manual variant.

- Cost: Depending on the type, complexity, and vehicle fit, transmissions can range in cost. A standard manual transmission might cost around $1,000 to $2,000, while high-end automatic transmissions can reach upwards of $4,000.

- Lifespan: A typical transmission’s lifespan is about 7-10 years, but this can vary based on maintenance, usage, and the quality of the materials used.

The Role of a Transmission in Vehicles

At its core, a transmission’s role is to ensure that the engine’s power is efficiently transmitted to the wheels, giving the vehicle its desired speed and torque. The transmission does this by shifting gears, which changes the ratio of engine speed to wheel speed.

Considerations regarding the role of transmissions:

- Advantages: A well-maintained transmission ensures smooth acceleration, better fuel efficiency, and a comfortable driving experience.

- Materials: Transmissions are typically made of sturdy materials like steel and aluminum to handle the stress and strains of driving.

- Speed and Efficiency: Modern automatic transmissions can shift gears in milliseconds, ensuring quick responses and efficient driving, especially in city conditions.

- Drawbacks: Without proper maintenance, transmissions can develop issues like slipping gears or overheating, leading to reduced performance and potentially hefty repair bills.

In conclusion, understanding the intricacies of transmissions, particularly the CVT, can provide insights into the vehicle’s performance, cost, and longevity.

History of CVT Transmission

The CVT (Continuously Variable Transmission) is not a modern marvel, as some might believe.

Early Beginnings

Leonardo da Vinci, a Renaissance polymath, is credited with sketching the first known designs of a continuously variable transmission in the late 15th century. While his concepts did not immediately lead to a working prototype, they laid the groundwork for future inventors to explore this innovative transmission mechanism.

In the late 19th century, several inventors and engineers began creating working models of CVT systems. One notable example from this time is Daimler’s “steel belt” CVT design from the 1880s.

Key highlights of early CVTs:

- Materials: Early CVTs primarily utilized materials like leather and basic metals, quite different from the advanced alloys and composites used today.

- Efficiency: These early designs weren’t particularly efficient, with substantial power losses. However, they demonstrated the potential of a transmission that could change ratios seamlessly.

- Cost: The lack of advanced machinery and refined techniques made the production of these early CVTs considerably expensive, often restricting their use to niche applications.

Evolution Over the Years

The 20th century saw significant advancements in CVT technology. Companies like Subaru in the 1980s popularized the CVT in their cars. The Subaru Justy was one of the first mass-produced vehicles to utilize a CVT, showcasing its potential in improving fuel efficiency and driving comfort.

As we moved into the 21st century, more and more manufacturers started incorporating CVTs into their vehicles due to their efficiency and the smooth driving experience they offer.

Key points from this era:

- Speed: Modern CVTs can handle a wide range of speeds, from city driving at 20 mph to highway speeds exceeding 80 mph.

- Efficiency: Thanks to advancements in materials and design, modern CVTs can achieve fuel efficiency improvements of up to 15% compared to traditional automatic transmissions.

- Lifespan: With proper maintenance, today’s CVTs can last up to 200,000 miles, a testament to their quality and reliability.

- Price: The cost of manufacturing CVTs has decreased over time.

In essence, the journey of the CVT from da Vinci’s sketches to today’s advanced vehicles is a testament to human ingenuity and the relentless pursuit of efficiency and innovation in the automotive sector.

Working Principle of CVT

The Continuously Variable Transmission (CVT) represents a marked departure from traditional transmission systems. Renowned for its unique operation and benefits, understanding its working principle can give insights into its growing popularity in today’s automotive landscape.

Basic Mechanics

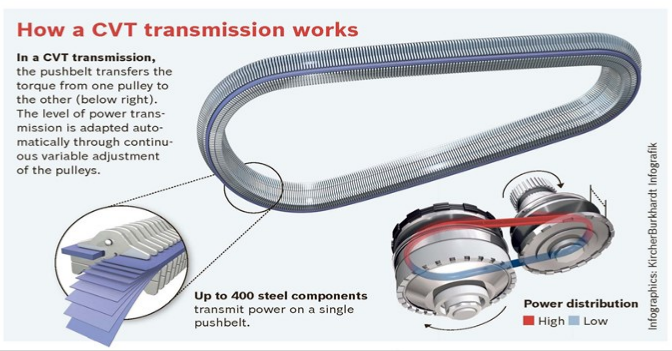

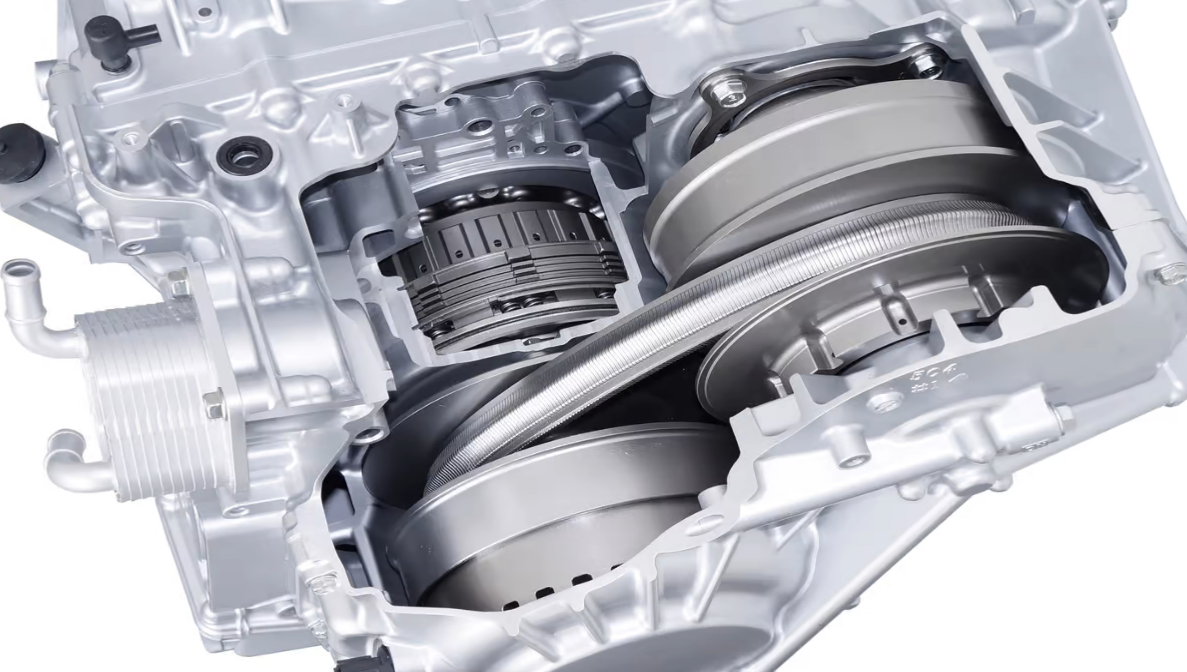

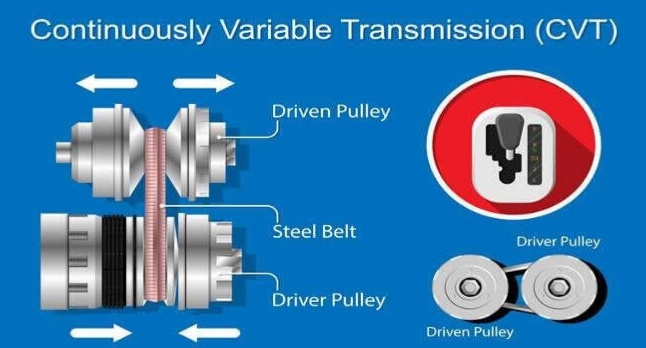

The core of a CVT system consists of two pulleys connected by a belt or chain. These aren’t just any pulleys; they are variable-diameter pulleys, meaning their effective diameter can change. As the engine operates, these pulleys can move closer together or further apart, effectively changing the diameter and thereby the gear ratio.

Key mechanics involved:

- Power Transfer: The engine generates power, usually measured in horsepower.

- Variable Pulley System: By adjusting the diameter of the pulleys, the CVT can change the gear ratio without the need for traditional gears. This variability can range from high torque at low speeds for rapid acceleration to low torque at high speeds for efficient cruising.

- Belt or Chain: Modern CVTs often use a metal belt or chain to connect the pulleys.

- Efficiency: CVTs can maintain the engine in its optimal power range, ensuring maximum fuel efficiency. For a given car, this might result in an improvement of 3-5 mpg compared to traditional transmissions.

- Cost: Manufacturing a CVT involves precision machinery and high-quality materials, potentially raising the price. However, the cost savings from fuel efficiency and reduced wear and tear often justify the initial investment.

How CVT Differs from Traditional Transmissions

Traditional transmissions, whether manual or automatic, use a fixed set of gears to achieve various speed-to-torque ratios. When you shift gears, you’re engaging a different set of gear sizes, leading to a momentary disconnection between the engine and the wheels.

Key differences:

- Seamless Transition: While traditional transmissions shift gears, leading to noticeable jerks or “gear hunting”, CVTs provide a smooth transition across all speeds.

- Number of Ratios: Traditional transmissions have a fixed number of ratios (e.g., 5-speed, 6-speed). In contrast, a CVT has, theoretically, an infinite number of ratios within its range, ensuring the engine always operates at peak efficiency.

- Materials and Construction: Traditional transmissions are built using a set of gears, which can add weight and complexity. CVTs, on the other hand, rely on their pulley system, often resulting in a simpler and more compact design.

- Maintenance: CVTs typically have fewer moving parts, leading to potentially lower maintenance costs over time. However, they do require specific transmission fluids and periodic checks to ensure the belt or chain remains in good condition.

In essence, the CVT stands out as an innovative solution in the automotive world, offering a combination of smooth performance and efficiency that’s hard to match with traditional transmission systems.

Types of CVTs

Continuously Variable Transmissions (CVTs) have seen multiple iterations and designs since their inception. Here’s a deep dive into the different types of CVTs.

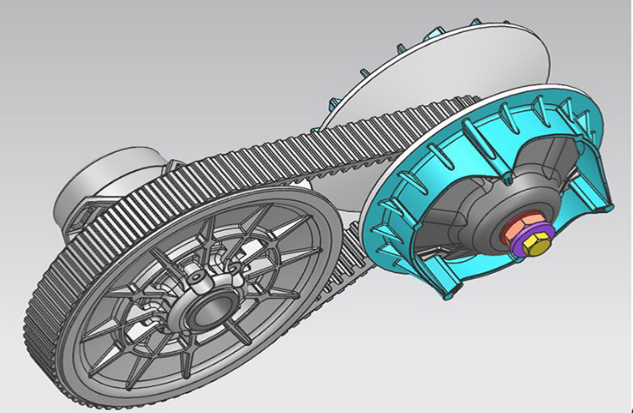

Pulley-Based CVTs

This is perhaps the most common type of CVT found in many of today’s vehicles. Pulley-based CVTs operate using two cone-shaped pulleys with a metal belt or chain running between them.

- How It Works: One pulley is attached to the engine, while the other connects to the wheels. These pulleys can change their diameter, enabling a wide range of gear ratios.

- Advantages: They offer smooth acceleration and can improve fuel efficiency by keeping the engine in its optimal power range. They’re also relatively compact and lightweight.

- Materials: Typically, these CVTs use a metal belt or chain, often made from high-quality steel or composite materials, ensuring durability.

- Cost: While manufacturing costs can be higher than traditional manual transmissions, the improved fuel efficiency and longevity often balance out the initial expense.

Toroidal CVTs

Toroidal CVTs differ from pulley-based systems. Instead of belts and pulleys, they utilize a set of rotating discs and power rollers.

- How It Works: The power transfer occurs between two rotating discs and rollers in between. By tilting the rollers, the contact diameter changes, varying the gear ratio.

- Advantages: They can handle higher torque loads compared to pulley-based systems, making them suitable for powerful vehicles.

- Materials: These CVTs are primarily made of hardened steel components to withstand the forces exerted by the discs and rollers.

- Drawbacks: They can be bulkier and often have a higher manufacturing cost due to the precision required in creating the components.

Hydrostatic CVTs

Hydrostatic transmissions, often used in heavy machinery and some agricultural vehicles, rely on fluid dynamics to transfer power.

- How It Works: This CVT uses a hydraulic pump and motor system. By varying the fluid flow between the pump and motor, the gear ratio changes.

- Advantages: They’re robust and can handle substantial loads, making them ideal for machinery that requires significant torque.

- Materials: Constructed using high-grade metals and specialized hydraulic fluids to ensure optimal performance and longevity.

- Cost: Given their complexity and the specialized materials used, hydrostatic CVTs can be quite expensive.

Adaptive CVTs

An emerging technology, adaptive CVTs can change their operation based on external conditions and driving requirements.

- How It Works: Using sensors and advanced algorithms, these CVTs adjust in real-time to driving conditions, ensuring optimal power delivery and efficiency.

- Advantages: They offer improved performance, fuel efficiency, and can adapt to various driving styles and conditions.

- Materials: A mix of traditional CVT components combined with advanced sensors and electronic modules.

- Price: Being a newer technology, they might come with a premium price tag, but offer significant improvements in adaptability and efficiency.

In summary, the world of CVTs is vast and diverse. The type of CVT chosen for a vehicle or machinery often depends on the specific requirements, be it torque, efficiency, or adaptability. The evolution of CVTs showcases the constant quest for better and more efficient transmission systems in the automotive and machinery sectors.

Advantages of CVT Transmission

The Continuously Variable Transmission (CVT) has rapidly gained traction in the automotive world, especially in passenger vehicles.

Efficiency Improvements

The design of the CVT ensures the engine operates in its most efficient range, regardless of the driving condition.

- Performance: Unlike traditional transmissions with a set number of gears, a CVT can adjust to any engine speed, ensuring optimal power delivery. This can translate to quicker acceleration when needed.

- Optimal RPM: The CVT keeps the engine’s revolutions per minute (RPM) in the ideal range. For instance, while a conventional transmission might shift through gears at specific RPM thresholds, a CVT can adjust continuously, ensuring the engine always operates near its peak efficiency.

- Reduced Wear and Tear: With fewer jerks and gear shifts, CVTs can reduce the strain on the engine and transmission system, potentially extending the lifespan of these components.

Smooth Driving Experience

One of the most noticeable benefits for drivers and passengers alike is the seamless driving experience provided by CVTs.

- No Gear Shifts: Drivers won’t experience the traditional jolts or pauses associated with gear changes. For example, during a 0-60 mph acceleration, a traditional transmission might shift gears five times, while a CVT provides a continuous, smooth acceleration.

- Consistent Power Delivery: Regardless of the driving situation – whether climbing a steep hill or overtaking on a highway – the CVT ensures consistent power delivery without the need to wait for the transmission to find the right gear.

- Quiet Operation: Without distinct gear shifts, the overall noise during acceleration is often reduced, contributing to a quieter cabin experience.

Enhanced Fuel Economy

Perhaps one of the most significant selling points of CVTs is their potential for improved fuel efficiency.

- Optimal Engine Operation: As mentioned, the CVT’s ability to keep the engine in its most efficient RPM range can lead to fuel savings. On average, vehicles equipped with CVTs might see an improvement of 3-7 mpg compared to their counterparts with conventional transmissions.

- Cost Savings: With today’s fuel prices, even a modest improvement in fuel economy can lead to substantial savings over the lifespan of a vehicle. For instance, a 5 mpg improvement, given a fuel cost of $3.50 per gallon and an average driving distance of 12,000 miles annually, could result in savings of over $200 per year.

In conclusion, the advantages of the CVT system span from tangible benefits like fuel savings to the intangible, such as a smoother driving experience. As technology progresses and further refinements are made to the CVT, its adoption rate in the automotive sector is set to grow even more.

Limitations and Challenges

While Continuously Variable Transmissions (CVTs) offer many benefits, they aren’t without their challenges and limitations. Understanding these can provide a more comprehensive view of the CVT landscape, helping users and manufacturers make informed decisions.

Performance Considerations

CVTs are designed primarily for smoothness and fuel efficiency, but this sometimes comes at the cost of raw performance.

- Power Loss: Some CVTs, especially early designs, may not transfer power as efficiently as traditional manual or automatic transmissions. This can sometimes lead to perceived sluggishness, especially during hard acceleration.

- High RPM Operation: Under hard acceleration, a CVT might keep the engine at very high RPMs to maximize power. While this is efficient, it can be disconcerting to drivers who are used to the RPM changes associated with gear shifts.

- Tuning Limitations: Performance enthusiasts who like to tune or modify their vehicles might find CVTs less accommodating than traditional transmissions. Adjusting parameters for better performance might be more challenging or even restricted in some CVTs.

Durability Concerns

There have been concerns about the long-term reliability and durability of CVTs, especially in high-torque applications.

- Belt and Chain Wear: CVTs using belts or chains might experience faster wear compared to gear systems in traditional transmissions. Regular maintenance and checks are essential to prevent unexpected failures.

- Heat Dissipation: CVTs can generate significant heat, especially under heavy load conditions. Inadequate cooling can lead to reduced lifespan and potential failures.

- Repair Costs: While CVTs have fewer moving parts, repairing or replacing a damaged CVT can be costly. Some components might be more expensive than those in traditional transmissions.

Driver’s Perception and Feedback

A significant challenge with CVTs lies in the realm of driver perception and feedback.

- Missing the “Feel”: Many drivers enjoy the tangible feedback of gear shifts. With CVTs offering a seamless experience, some drivers might feel disconnected from the driving process.

- Engine Noise: As mentioned earlier, the constant high RPMs during acceleration can lead to sustained engine noise, which might be off-putting for some drivers.

- Learning Curve: Drivers transitioning from traditional transmissions to CVTs might require time to adjust. The absence of noticeable gear shifts and the distinct behavior of CVTs can take getting used to.

In summary, while CVTs offer many advantages, they come with their set of challenges. As with any technology, continuous refinement and understanding user feedback are essential to address these challenges and push the boundaries of what CVTs can offer.

Modern Applications of CVT

Continuously Variable Transmissions (CVTs) have evolved significantly since their inception, proving their worth in various applications. From everyday vehicles to specialized machinery, CVTs have carved out a niche thanks to their distinct operational advantages.

In Passenger Cars

The automotive sector remains the most prominent user of CVTs, leveraging its benefits for a smoother and more efficient driving experience.

- Mainstream Acceptance: Major automotive brands like Nissan, Subaru, and Honda have integrated CVTs into many of their popular models, making them a common sight on roads today.

- Fuel Efficiency: Cars with CVTs, on average, can achieve a fuel efficiency improvement of 5% to 10%, translating to noticeable savings at the gas pump for consumers.

- Compact Design: Modern CVTs have become increasingly compact, making them ideal for smaller cars where space optimization is critical.

- Versatility: Whether it’s city driving with frequent stops or highway cruising, the adaptive nature of CVTs ensures optimal engine performance.

In Industrial Machinery

Beyond cars, CVTs have made their mark in various industrial applications.

- Agricultural Equipment: In farming machinery like tractors, CVTs provide the advantage of maintaining constant engine speed, ensuring consistent power delivery, essential for tasks like plowing or seeding.

- Power Tools: Some high-end power tools employ CVTs to allow users to adjust the tool’s speed without altering the engine’s RPM, leading to better control and precision.

- Conveyors: In industrial settings, CVTs in conveyor systems can adapt to different production rates, ensuring smooth operations without abrupt starts or stops.

Hybrid and Electric Vehicles

The world of electric and hybrid vehicles presents a new frontier for CVTs.

- Optimized Energy Use: Especially in hybrid cars, CVTs can optimize power delivery between the electric motor and the gasoline engine, ensuring maximum efficiency and extended battery life.

- Seamless Transition: In hybrids, transitioning between electric and gasoline propulsion can be smoother with a CVT, enhancing the overall driving experience.

- Adapting to New Technology: As electric vehicle (EV) technology evolves, there’s potential for CVTs to play a role in multi-motor setups, ensuring harmonized power delivery between different motors.

- Range Extension: Some experts believe that CVTs in EVs could help in increasing the vehicle’s range by ensuring the motor always operates in its most efficient range.

In conclusion, the modern applications of CVTs stretch far beyond their initial use cases. As industries recognize their unique attributes, the adoption of CVTs is poised to grow across various sectors, underlining their versatility and potential.

Maintenance and Care for CVTs

For Continuously Variable Transmissions (CVTs) to function optimally, proper maintenance is crucial. CVTs, while known for their efficiency and smooth operation, require specific care to prolong their lifespan and ensure consistent performance.

Recommended Service Intervals

Just like any other component of a vehicle, CVTs have recommended service intervals that owners should adhere to.

- Transmission Fluid Checks and Changes: It’s essential to regularly check the transmission fluid levels. Typically, for most CVTs, the fluid should be changed every 60,000 to 100,000 miles. However, always refer to the vehicle’s owner manual, as some manufacturers might have specific recommendations.

- Belt Inspection: The belts in a CVT should undergo inspection every 40,000 miles.

- Overall Inspection: An overall CVT inspection, which includes checking for leaks, assessing fluid quality, and evaluating component integrity, should be done annually or every 20,000 miles, whichever comes first.

Common Issues and How to Address Them

Even with the best care, CVTs can face issues. Recognizing these problems early can help in addressing them promptly.

- Slipping Transmission: One of the common complaints with CVTs is the feeling of a “slipping” transmission, where the vehicle doesn’t accelerate as it should. This can often be due to low transmission fluid or worn-out belts. Addressing this involves checking and possibly changing the fluid or replacing the belt.

- Overheating: CVTs can overheat, especially when subjected to heavy loads or constant high-speed driving. If the transmission temperature warning light illuminates, it’s crucial to stop the vehicle and let it cool down. Regularly checking the cooling system and ensuring the transmission fluid is of good quality can prevent this issue.

- Noisy Operation: A CVT that’s becoming noisy, especially during start-up, could be an indication of low fluid levels or degraded fluid quality. A fluid change might resolve the problem, but if it persists, a deeper inspection by a professional might be necessary.

- Delayed Response: If there’s a noticeable delay in acceleration after pressing the accelerator pedal, it might indicate wear in the CVT components. Such issues require a comprehensive check by a trained technician to identify the root cause.

In conclusion, while CVTs offer numerous advantages, they also have specific maintenance needs. Adhering to recommended service intervals and being vigilant about potential issues ensures the transmission remains in top shape, providing a smooth and efficient driving experience.

Future of CVT Transmission

The automotive industry is ever-evolving, and the world of transmissions is no exception. The Continuously Variable Transmission (CVT) has undergone significant advancements in the past few decades, and its future looks promising with technological innovations and the growing electric vehicle market.

Technological Innovations

CVTs have come a long way since their inception, but manufacturers continue to invest in research and development to further refine their performance, efficiency, and reliability.

- Advanced Materials: As the demand for lightweight vehicles grows, the industry explores advanced materials like high-strength steel and composites for CVT components. These materials can reduce the CVT’s weight, thereby improving fuel efficiency, without compromising its durability. For instance, a new composite belt in development could potentially handle power outputs of up to 400 horsepower while reducing the overall transmission weight by 10%.

- Electronic Integration: The integration of advanced electronics into CVTs can enhance their adaptability and responsiveness. Adaptive algorithms, for example, can adjust the CVT’s behavior based on driving conditions, optimizing for either performance or fuel efficiency in real-time.

- Improved Cooling Systems: Overheating remains a challenge for many CVTs. New designs, using advanced cooling techniques and materials, aim to dissipate heat more efficiently, ensuring consistent performance even under heavy loads.

Potential in Electric Vehicle Market

While many people associate electric vehicles (EVs) with single-speed transmissions, there’s growing interest in the potential benefits CVTs can offer in this space.

- Efficiency Optimization: Although electric motors deliver a broad torque range, using a CVT can optimize the motor’s efficiency across different driving conditions. For instance, during highway cruising, the CVT can adjust to ensure the motor operates at its most efficient speed, thus extending the vehicle’s range.

- Performance: High-performance EVs could benefit from CVTs by ensuring the electric motor always operates in its peak performance range. This could result in faster acceleration times and improved overall vehicle dynamics.

- Integration with Regenerative Braking: As regenerative braking becomes a standard feature in EVs, CVTs can play a role in optimizing the energy recovery process.

The future of CVTs looks bright, with the potential to contribute significantly to the ongoing evolution of the automotive industry. With continuous advancements in technology and a growing interest in their application in electric vehicles, CVTs may soon redefine the way we perceive vehicle transmissions.

Conclusion

As we delve deep into the world of automotive transmissions, the significance and role of Continuously Variable Transmission (CVT) stand out as a pivotal innovation in modern automotive history. The CVT has reshaped how vehicles transfer power, bringing forth an era of seamless acceleration and improved efficiency.

Recap of CVT’s Role and Significance

The introduction of CVT marked a departure from traditional fixed-gear transmissions. This innovation has played a central role in the automotive industry’s pursuit of optimal performance and fuel efficiency.

- Revolutionizing Efficiency: CVTs, by nature, operate by continuously finding the engine’s most efficient operating point. Compared to traditional transmissions that might operate at peak efficiency only 60-70% of the time, CVTs can achieve efficiency levels of up to 88%.

- Seamless Driving Experience: Unlike conventional transmissions that offer a finite number of gear ratios, CVTs provide an infinite range, ensuring drivers experience smoother acceleration. There’s no noticeable “gear shift” – it’s a continuous flow of power, giving the sensation of a single, endless gear.

- Fuel Economy: CVTs have paved the way for vehicles to achieve better fuel consumption rates. Some models equipped with CVTs report a 10% improvement in fuel economy compared to their fixed-gear counterparts.

- Versatility: From compact cars to industrial machinery, CVTs have showcased their adaptability, offering a broad application spectrum.

Looking Ahead

As we gaze into the future of the automotive industry, the relevance of CVTs becomes even more pronounced.

- Evolving with Electric Vehicles (EVs): Although EVs primarily employ single-speed transmissions, there’s growing interest in leveraging CVTs to optimize motor efficiency, potentially enhancing range and performance.

- Innovation-Driven Future: As research continues, there are whispers about CVTs capable of handling even greater power outputs – envision a CVT that can efficiently manage a staggering 500 horsepower.

- Acceptance and Popularity: As more drivers become acquainted with the benefits of CVTs, their acceptance and popularity are bound to grow. Additionally, as manufacturers focus on educating consumers about the advantages, we can expect a more substantial shift towards CVT-equipped vehicles.

The continuous drive towards efficiency, combined with the innate advantages of CVTs, ensures that this technology remains at the forefront of automotive innovation.