An Electric Drive Axle is a key component of electric and hybrid vehicles, responsible for converting the electrical energy from the motor into mechanical energy to drive the wheels.

It consists of the electric motor, power electronics, transmission system, and a cooling system.

Introduction to Electric Drive Axle

The electric drive axle, an integral component of electric and hybrid vehicles, is the result of continuous advancements in automotive technology. It is the culmination of decades of effort to reduce the carbon footprint and improve the energy efficiency of vehicles.

Brief Historical Background

The concept of an electric axle, or eAxle, is not entirely new. Electric propulsion has been a part of automotive history since the late 19th century, with innovators experimenting with electrically powered vehicles. However, these early prototypes were unable to compete with the convenience and cost-effectiveness of gasoline engines. It was not until the late 20th and early 21st centuries that the pursuit for greener, more efficient transportation options led to a resurgence in electric vehicle technology. This eventually paved the way for the development of modern electric drive axles.

Definition of Electric Drive Axle

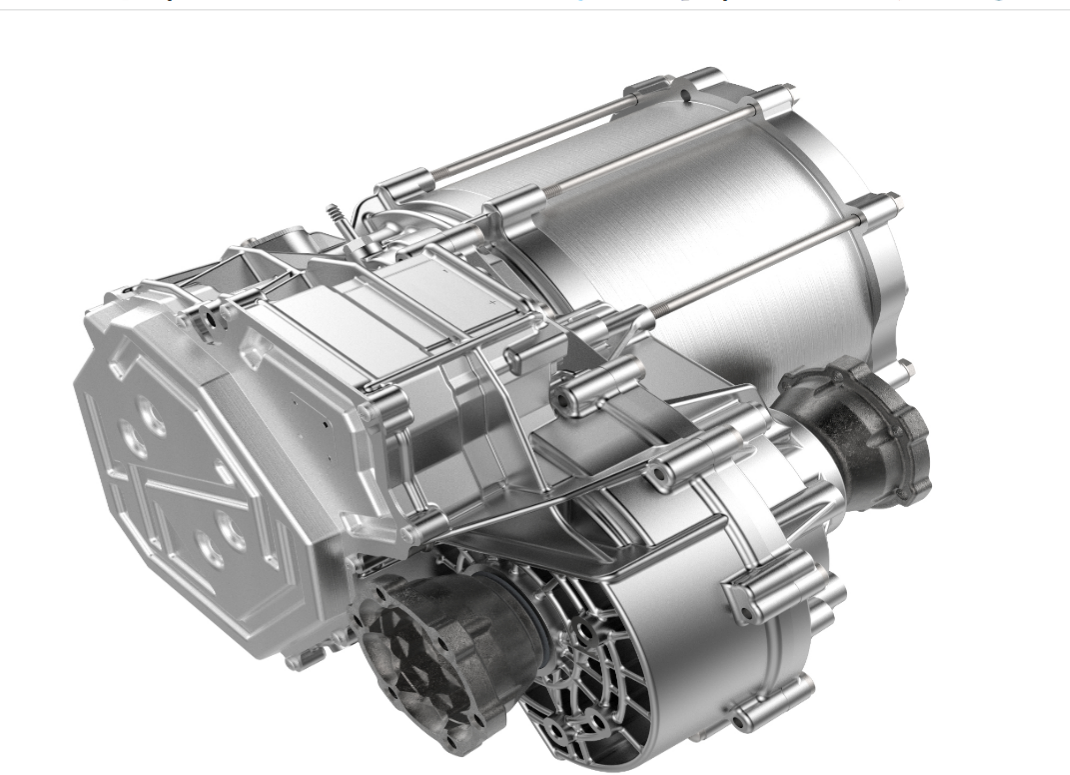

An electric drive axle is a component of an electric vehicle’s drivetrain that combines the electric motor, transmission, and differential into a single unit that drives the vehicle’s wheels. Unlike a traditional axle in a combustion engine vehicle, an electric drive axle generates torque from an electric motor and transmits this power directly to the wheels. It simplifies the drivetrain, improves energy efficiency, and reduces weight and space requirements in the vehicle.

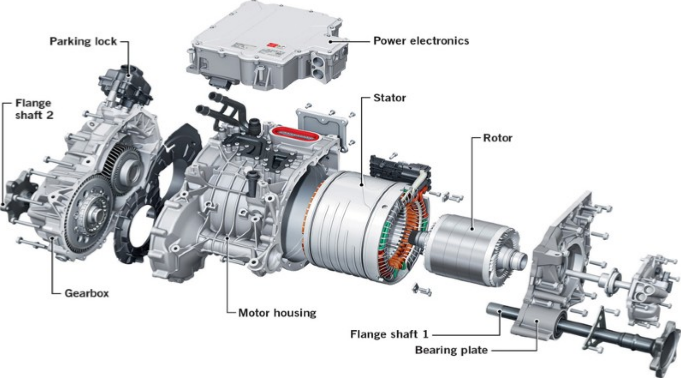

Components of an Electric Drive Axle

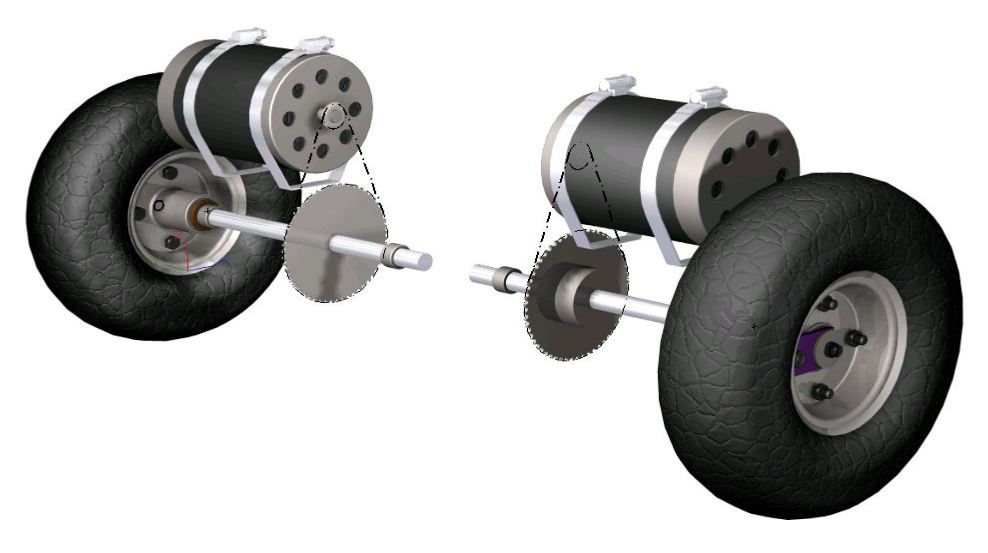

An electric drive axle is composed of several key components that work together to transform electrical energy into mechanical energy, allowing the vehicle to move.

Electric Motor

The electric motor is the heart of the electric drive axle. It is responsible for converting electrical energy into mechanical energy. In the context of electric vehicles, most use either AC induction or DC brushless motors, as they are known for their high efficiency and reliability. The electric motor generates torque that is sent to the wheels of the vehicle, propelling it forward.

Power Electronics

Power electronics control the flow of electricity to and from the electric motor. The main component of the power electronics is the inverter, which converts direct current (DC) from the vehicle’s battery into alternating current (AC) that powers the motor. Power electronics also include the converter and controller which manage power flow, control motor speed and regulate the entire drive system’s operation.

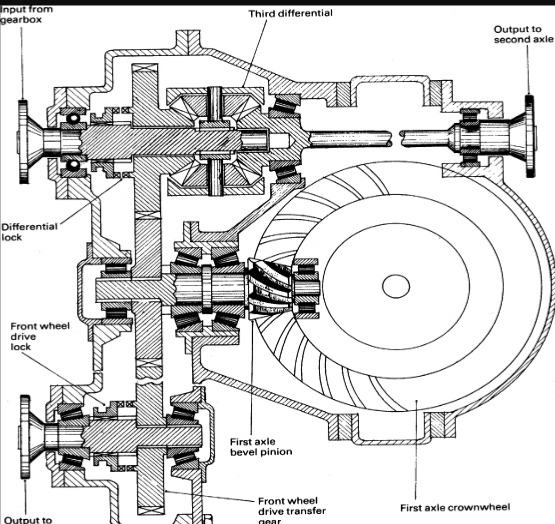

Transmission System

The transmission system in an electric drive axle is generally simpler than that found in traditional combustion vehicles, often consisting of a single-speed reduction gear. The primary purpose of the transmission system is to transfer the torque generated by the electric motor to the vehicle’s wheels at an appropriate speed and force.

Cooling System

Electric vehicles generate heat during operation, especially during high-speed driving or quick acceleration. Therefore, an efficient cooling system is crucial. It ensures the electric motor, power electronics, and other components operate within their optimal temperature range. The cooling system usually consists of a coolant and a series of pipes and radiators that distribute and dissipate heat to prevent overheating and prolong the life of the vehicle’s components.

Types of Electric Drive Axles

The type of electric drive axle a vehicle utilizes largely depends on the kind of drivetrain it possesses. Here, we look at three main types: front, rear, and four-wheel drive configurations.

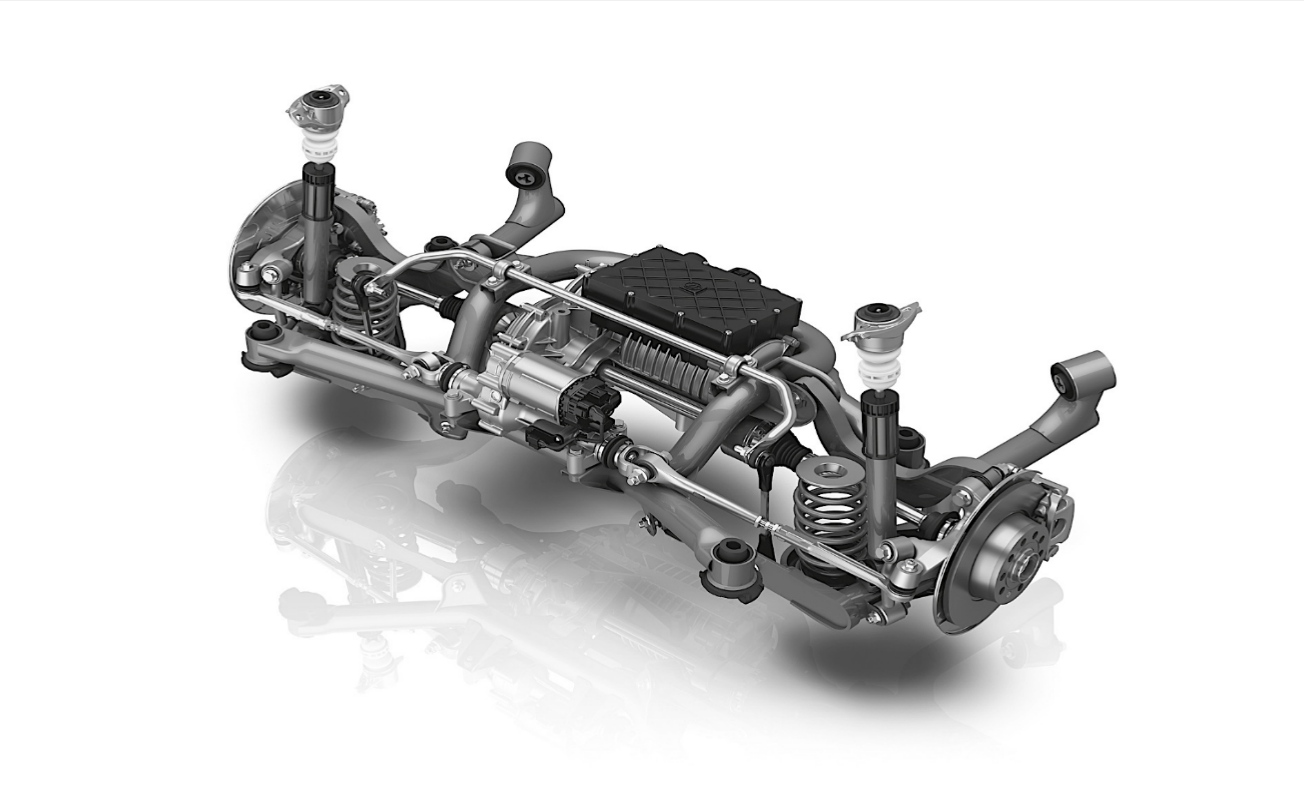

Front Drive Axle

In a front drive axle configuration, the electric motor and the drive system are located at the front of the vehicle. This configuration, often found in Front Wheel Drive (FWD) vehicles, typically offers more interior space and is generally cheaper to manufacture. Moreover, as the weight of the drive system is over the driven wheels, FWD vehicles often offer better traction in conditions such as climbing hills or driving in snow.

Rear Drive Axle

For Rear Wheel Drive (RWD) vehicles, the electric drive axle is located at the back of the vehicle. It allows for better weight distribution between the front and rear wheels, resulting in improved balance and stability, especially at high speeds or during cornering.

Four-Wheel Drive

In a Four-Wheel Drive (4WD or 4×4) configuration, both the front and rear axles are driven by the motor, often through two separate electric drive axles. This configuration provides superior traction and control, particularly in off-road conditions or challenging weather.

Working Principle of Electric Drive Axle

The electric drive axle operates on the principle of converting electrical energy into mechanical energy, powering the wheels of a vehicle.

Energy Conversion Process

At the heart of the energy conversion process is the electric motor. It starts with the vehicle’s battery supplying direct current (DC) to the inverter. The inverter, part of the power electronics, then converts DC into alternating current (AC). This AC powers the electric motor, which produces torque. The transmission system transfers this torque to the wheels, propelling the vehicle.

Role of Each Component

Each component in an electric drive axle plays a critical role:

- The electric motor produces torque from electrical energy.

- Power electronics control the flow of electricity, ensuring efficient energy conversion.

- The transmission system adapts and transfers the motor’s torque to the wheels.

- The cooling system maintains optimal operating temperatures, ensuring the longevity and performance of the electric drive axle and its components.

Control Systems

Modern electric vehicles employ advanced control systems to manage and optimize the performance of the electric drive axle. These systems use a variety of sensors and software algorithms to adjust the electric motor’s torque output, the power electronics’ energy flow, and the transmission system’s torque distribution to the wheels. By continually monitoring and adjusting these parameters, the control systems ensure optimal performance, efficiency, and safety of the vehicle in different driving conditions.

Benefits of Electric Drive Axles

Electric drive axles bring several significant advantages compared to traditional drivetrains, including efficiency and performance improvements, reduced environmental impact, and lower maintenance costs.

Efficiency and Performance

Electric drive axles are incredibly efficient. They convert a larger percentage of the electrical energy from the battery to drive the wheels, unlike internal combustion engines which lose a significant amount of energy as heat. This efficiency translates into longer ranges for electric vehicles. Additionally, electric motors can provide maximum torque from a standstill, resulting in excellent acceleration performance.

Environmental Impact

Electric drive axles have a significantly lower environmental impact compared to traditional drivetrains. Furthermore, the simplicity of electric drive axles allows for better energy efficiency, which also contributes to lower carbon emissions per mile.

Cost and Maintenance

Electric drive axles have fewer moving parts compared to traditional drivetrains, reducing the likelihood of mechanical failure. This translates into less frequent maintenance and lower maintenance costs over the vehicle’s lifespan. In addition, the cost of electricity is typically lower than gasoline or diesel on a per-mile basis, resulting in lower fueling costs. The total cost of ownership (TCO) for vehicles with electric drive axles can be significantly lower when considering these savings in fuel and maintenance.

Applications of Electric Drive Axles

Electric drive axles have a wide range of applications, playing a key role in the operation of various types of vehicles, including electric vehicles, hybrid vehicles, and heavy-duty commercial vehicles.

In Electric Vehicles

Electric vehicles (EVs) fully rely on electric drive axles to deliver power from the motor to the wheels. Whether it’s a front, rear, or all-wheel drive, electric drive axles provide the necessary torque for the vehicle’s movement. Moreover, their efficiency and simplicity help maximize the vehicle’s range and performance. This key component is what enables electric vehicles to offer smooth acceleration, regenerative braking, and other advanced features.

In Hybrid Vehicles

Hybrid vehicles use a combination of an internal combustion engine and one or more electric motors. This use of electric drive axles is a crucial part of what makes hybrid vehicles more fuel-efficient and eco-friendly than traditional internal combustion vehicles.

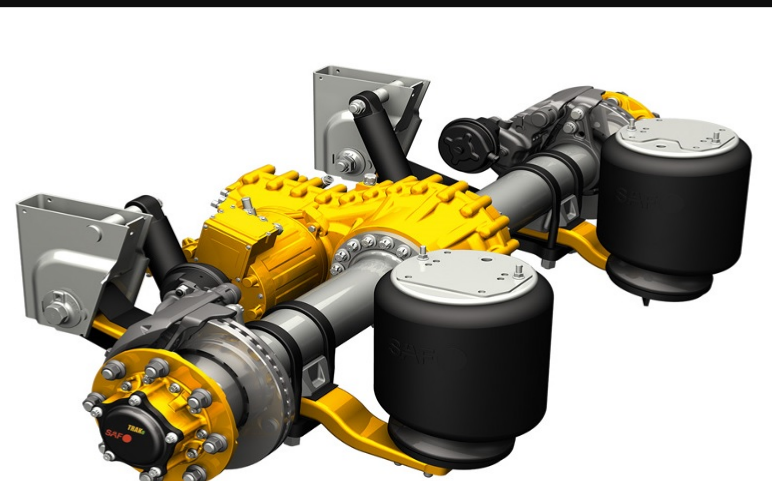

In Heavy-Duty Commercial Vehicles

Heavy-duty commercial vehicles, such as trucks and buses, have also started to adopt electric drive axles. With the increasing need for sustainable and efficient transport solutions, these vehicles benefit greatly from the improved torque delivery, efficiency, and reduced maintenance costs offered by electric drive axles. In the heavy-duty sector, electric drive axles can help lower operating costs, reduce emissions, and meet increasingly stringent environmental regulations.

Future Trends and Developments

As the world moves towards sustainable transport solutions, the electric drive axle technology is poised to evolve with new innovations, market trends, and regulatory changes.

Technological Innovations

The ongoing advancements in electric motor technology, power electronics, and battery technology will further improve the performance, range, and efficiency of electric drive axles. Advances in power electronics will allow for more efficient energy conversion, while improved battery technology will increase energy density, thereby increasing the range of electric vehicles. Innovations in the field of artificial intelligence and machine learning will enhance the control systems, leading to smarter and more efficient operation of the electric drive axles.

Market Trends

Market trends indicate a growing shift towards electric and hybrid vehicles, driven by increasing consumer awareness of environmental issues and the lowering costs of EV technology. This shift will continue to fuel demand for electric drive axles.

Regulatory Impact

Governments worldwide are enacting stricter emission standards and providing incentives for EV adoption to combat climate change. These regulatory actions will have a significant impact on the electric drive axle market. For instance, the ban on new petrol and diesel cars in some countries will drive demand for electric and hybrid vehicles, thereby boosting the need for electric drive axles. Additionally, incentives for electric and hybrid vehicle purchases, and penalties for high-emission vehicles will further influence market trends. As such, it’s evident that regulatory changes will play a key role in shaping the future of electric drive axles.

Challenges and Limitations

While electric drive axles offer numerous advantages, there are still a number of challenges and limitations that need to be addressed to fully realize their potential.

Technical Challenges

One of the primary technical challenges for electric drive axles is improving energy efficiency and power density while keeping the size and weight to a minimum. This requires ongoing research and development into new materials and design methodologies. Ensuring that the drive axle and its components can handle the high loads and stresses encountered in various driving conditions is also essential.

Cost Barriers

Despite the falling prices of electric vehicle technology, cost remains a significant barrier. The initial purchase price of electric vehicles remains higher than comparable internal combustion engine vehicles, in large part due to the high cost of batteries. This extends to the electric drive axle components too, such as the electric motor and power electronics.

Infrastructure Needs

The broad adoption of electric drive axles in vehicles also hinges on the availability of charging infrastructure. Without widespread and convenient charging stations, the practicality of electric vehicles remains limited, particularly for long-distance travel. Furthermore, the electric grid itself may need upgrades to handle the increased demand that widespread electric vehicle use would entail. Addressing these infrastructure needs is crucial for the widespread adoption of electric drive axle technology.

Conclusion

As we delve into the subject of electric drive axles, it becomes clear how they are integral components in shaping the future of transportation.

Summary of Key Points

Electric drive axles are vital elements of electric and hybrid vehicles, delivering power from the motor to the wheels. They consist of key components like the electric motor, power electronics, transmission system, and cooling system. Electric drive axles come with various benefits such as improved efficiency and performance, reduced environmental impact, and lower maintenance costs. However, they also present some challenges and limitations, including technical issues, cost barriers, and infrastructure needs.

Future Prospects

Despite these challenges, the future of electric drive axles appears promising. Continuous innovation and research are key to overcoming existing challenges and unlocking the full potential of this technology. With the pressing need for sustainable transportation solutions, electric drive axles will undoubtedly play a crucial role in our journey towards a greener and more efficient transportation future. Thus, the prospects for the electric drive axle market appear bright, and it will be exciting to see how this sector evolves in the years to come.