what does a hydraulic pump do? a hydraulic pump converts mechanical energy into hydraulic energy, creating a flow of fluid that can be used to perform work. Now, let’s delve into the specifics of these ingenious devices.

Definition of Hydraulic Pumps

A Hydraulic Pump is a mechanical device that generates flow or pressurizes fluid in a hydraulic system. It operates based on the displacement principle, converting mechanical energy into hydraulic energy. The pump does this by drawing fluid into its inlet, trapping it, and forcing it out through its outlet. For a more comprehensive understanding, you may refer to the Hydraulic Pump Wikipedia Page.

Brief History of Hydraulic Pumps

Hydraulic technology traces its roots back to the ancient times, but the real development started with Blaise Pascal’s principles established in the 17th Century. The first true hydraulic pump was introduced by Joseph Bramah in the 18th Century. This paved the way for the development of a wide variety of hydraulic pumps that we use today in different industries.

The Role and Importance of Hydraulic Pumps

Basic Function of a Hydraulic Pump

The fundamental function of a hydraulic pump is to convert mechanical energy from a power source, such as an electric motor or combustion engine, into hydraulic energy. This energy is used to move fluid within a system, creating flow that allows work to be done at various points of application.

Importance of Hydraulic Pumps in Different Industries

Hydraulic pumps are crucial components in many industries including construction, manufacturing, aviation, and more. They are used in hydraulic machinery and equipment such as excavators, hydraulic presses, and aircraft flight control systems. Their ability to efficiently transmit power makes them vital in systems that require high levels of force or torque. More about their industry applications can be found on the Hydraulic Machinery Wikipedia Page.

Types of Hydraulic Pumps

There are numerous types of hydraulic pumps designed for various applications, each with its own advantages and disadvantages. Some of the most common types include:

Gear Pumps

Gear pumps are simple and economical pumps that use the meshing of gears to pump fluid by displacement.

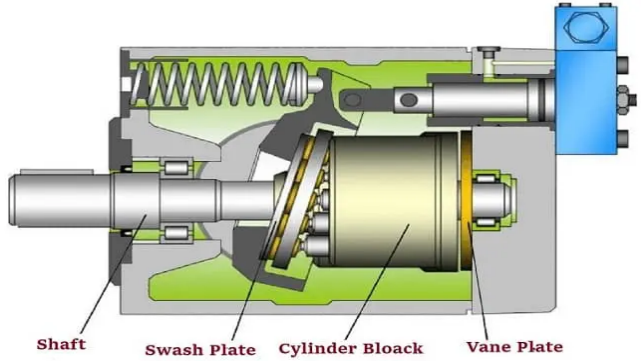

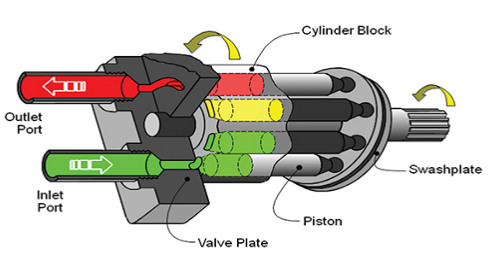

Piston Pumps

Piston pumps are more complex and can handle higher pressures compared to gear pumps. They use an arrangement of pistons to pump fluid.

Vane Pumps

Vane pumps utilize a series of vanes that expand and contract to create fluid flow. They are suitable for mid-pressure applications.

You may find more about these pump types on the Hydraulic Pump Wikipedia Page.

Differences and Use Cases

The following table gives a brief comparison of the different types of hydraulic pumps:

| Pump Type | Best Suited For | Pressure Handling | Complexity |

|---|---|---|---|

| Gear Pumps | Steady, simple flow of fluid | Low pressure | Simple |

| Piston Pumps | Heavy-duty applications | High pressure | Complex |

| Vane Pumps | Mid-pressure applications | Mid pressure | Moderate |

Working Principle of Hydraulic Pumps

Hydraulic pumps operate on the principle of converting mechanical energy into hydraulic energy. Let’s delve deeper into this process.

Basic Principles

At the heart of the hydraulic pump’s operation is Pascal’s Law, which states that any change in pressure on an incompressible fluid within a closed system is transmitted equally in all directions within the fluid. This is the fundamental principle that allows hydraulic pumps to generate flow or pressurize fluid. More details can be found on the Pascal’s Law Wikipedia Page.

Detailed Process of How a Hydraulic Pump Works

A hydraulic pump works by creating a vacuum at the pump inlet using mechanical action. Fluid from the reservoir fills this vacuum and is then mechanically forced out of the pump outlet and into the hydraulic system. The pump’s output per cycle is constant. This cycle repeats, facilitating continuous fluid flow. For a detailed understanding of the working process, please refer to this Wikipedia Page.

Factors Influencing Hydraulic Pump Performance

Various factors can influence the performance of a hydraulic pump. Here, we delve into some of the key aspects to consider when looking at pump performance.

Pump Flow Rate

The flow rate of a hydraulic pump is the volume of fluid that the pump can move per unit of time. It is typically measured in gallons per minute (GPM) or liters per minute (LPM). Flow rate is crucial because it directly affects the speed of operation of a hydraulic system. A higher flow rate equates to faster system operation. Etransaxle Blog has a series of detailed articles discussing the importance of pump flow rate.

Pressure Limitations

The pressure limitations of a hydraulic pump refer to the maximum and minimum pressure that a pump can efficiently operate at. Operating a pump beyond its pressure limits can cause damage and reduce the lifespan of the pump. For more information on this subject, refer to this Hydraulic Pressure Wikipedia Page.

Efficiency Considerations

Efficiency in hydraulic pumps refers to the ratio of useful power output to the total power input. Factors such as pump design, operating conditions, and maintenance can influence pump efficiency. Etransaxle Blog provides more insights on efficiency considerations in their hydraulic pump series.

Maintenance and Troubleshooting of Hydraulic Pumps

Regular maintenance and effective troubleshooting are critical for the longevity and optimal performance of hydraulic pumps.

Regular Maintenance Practices

Proper maintenance of hydraulic pumps can prolong their lifespan and ensure they operate efficiently. This includes regular inspection, cleaning, and lubrication. Moreover, replacing worn-out components before they fail can prevent system downtime. Etransaxle Blog has some useful maintenance tips for hydraulic pumps in their blog section.

Common Problems and Troubleshooting Techniques

Hydraulic pumps can develop various problems, including excessive noise, overheating, and reduced performance. Identifying these issues early can help prevent costly repairs or replacements. Techniques for troubleshooting include checking for leaks, monitoring temperature and pressure levels, and looking for signs of component wear or damage. For more in-depth knowledge about troubleshooting hydraulic systems, you may refer to this Wikipedia Page. Etransaxle Blog also offers comprehensive guides on troubleshooting hydraulic pumps.

Technological Advancements and Future of Hydraulic Pumps

In the ever-evolving world of technology, hydraulic pumps have also seen substantial advancements enhancing their efficiency, durability, and scope of application.

Recent Technological Innovations

Over the years, hydraulic pump design and manufacturing have benefitted from various technological innovations. These advancements have resulted in pumps that are more efficient, quieter, and more durable than their predecessors. Improvements in materials science have led to more durable pump components, while advances in fluid dynamics have allowed for more efficient pump designs. For more on recent developments, you can check the Hydraulic Machinery Wikipedia Page.

Future Trends in Hydraulic Pump Technology

Looking ahead, we can expect hydraulic pump technology to continue evolving. The focus is likely to remain on increasing efficiency and reducing environmental impact. This might include developments in pump materials to reduce weight and increase durability, or new pump designs that reduce energy consumption and noise levels.

Safety Measures for Using Hydraulic Pumps

Working with hydraulic pumps involves certain risks, so it’s crucial to take safety precautions.

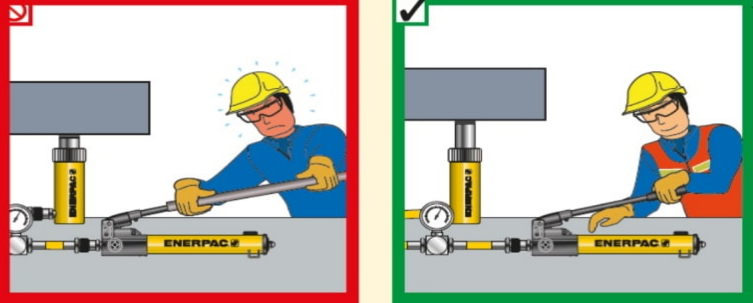

Safety Precautions During Use

While operating hydraulic pumps, it is important to ensure that the pump is not exposed to pressures above its maximum rating, as this can cause catastrophic failure. Additionally, care should be taken to avoid contact with high-pressure hydraulic fluid, which can cause injury. Further safety details can be found on the Hydraulic Safety Wikipedia Page.

Safety Equipment and Best Practices

Safety equipment such as gloves, goggles, and protective clothing can help prevent injuries when working with hydraulic pumps. Regular inspection and maintenance of the hydraulic system, including the pump, can also prevent failures that could pose safety risks.

Conclusion

Recap of Key Points

We’ve covered a lot of ground in this discussion about hydraulic pumps. We started with the basic definition and history, explored the various types and their operating principles, discussed the factors that influence pump performance, and looked at maintenance and troubleshooting techniques.

Final Thoughts

While there’s a lot more to hydraulic pumps than we can cover in a single article, we hope this overview gives you a solid foundation to further explore this fascinating topic. Hydraulic pumps, with their ability to transform mechanical energy into hydraulic power, are truly at the heart of modern industry. As technology continues to evolve, we can expect to see even more exciting advancements in this field.

I hope this article gives you a comprehensive answer to “What does a hydraulic pump do?” and provides insights into its importance and functionality in different industries and technologies.