CVT failures in Nissan are often due to manufacturing defects, poor transmission fluid, and overheating.

Primary Causes of CVT Failure in Nissan

Manufacturing Defects

Issues at the Production Stage

The process of making CVTs requires precision and high-quality materials. Sometimes, variations in the production process can introduce flaws. For instance, slight imperfections in metal casting or machining can lead to premature wear or breakage of components.

Component Quality Discrepancies

Not all parts used in Nissan CVTs come from the same supplier. Differences in component quality can lead to performance issues or failures. For instance, bearings from a lower-quality batch may not last as long as those from a higher-quality batch.

Inadequate Transmission Fluid Levels or Quality

Importance of Proper Fluid Levels

Transmission fluid acts as a lubricant and coolant for the CVT. Running the CVT with low fluid levels can cause excessive friction and heat, both of which can damage the transmission.

The Role of Fluid Quality

Using the wrong type of fluid or a degraded fluid can negatively impact CVT performance. It’s crucial to use the recommended transmission fluid specified for Nissan CVTs to ensure longevity and proper functioning.

Overheating Issues

Heat Generation in CVTs

All transmissions generate heat, but CVTs can be particularly sensitive to excessive temperatures. Overheating can occur due to extended periods of aggressive driving, heavy towing, or driving in extreme conditions.

Consequences of Overheating

When a CVT overheats, it can cause components to wear out faster. Over time, this can lead to the transmission belt becoming brittle or other parts like the torque converter malfunctioning.

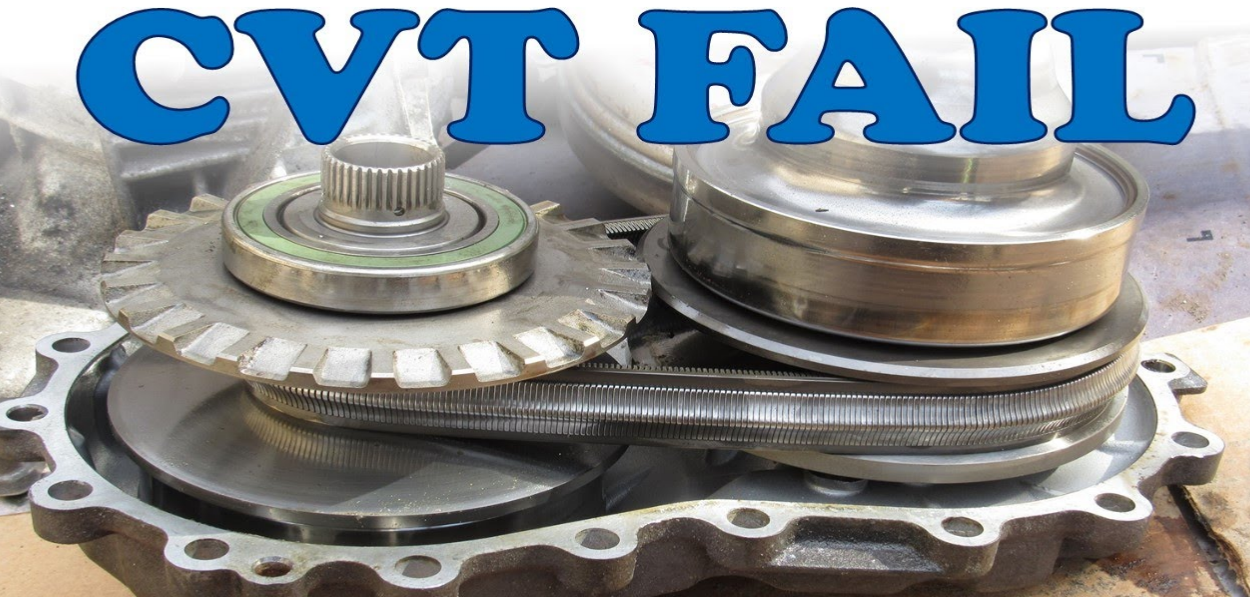

Belt Slippage

Causes of Slippage

The belt in a CVT can slip due to wear, improper tension, or contamination (like oil or debris). This slippage can affect the CVT’s ability to change ratios smoothly.

Effects on Driving Experience

When the belt slips, drivers might notice a loss of acceleration, jerky movements, or an unresponsive throttle. This can be particularly noticeable when trying to overtake another vehicle or when driving uphill.

Wear and Tear of CVT Components

Natural Wear Over Time

Like all mechanical systems, CVTs have components that degrade over time. Regular use, combined with external factors like road conditions and driving habits, can expedite this wear.

Impact on Longevity and Performance

As components wear out, they can cause the CVT to operate less efficiently. For instance, worn-out clutches might not engage properly, leading to rough shifts or unpredictable behavior.

Secondary and Less Common Causes

Software and Calibration Issues

Role of Software in Modern CVTs

Modern CVTs rely heavily on software for their operation. This software determines how and when the CVT shifts, based on factors like engine load, speed, and throttle position. Incorrect software versions or bugs can lead to erratic behavior.

Calibration Challenges

Proper calibration ensures the CVT operates seamlessly with the engine. Mismatches in calibration, whether from factory settings or post-production updates, can cause suboptimal performance. It’s like having a misaligned gearbox, where the gears don’t quite match up.

External Factors (e.g., accidents or environmental conditions)

Impact of Accidents

A major collision or accident can cause physical damage to the CVT or misalignment of its components. Even if the vehicle seems drivable, internal damage might be present, leading to future CVT issues.

Environmental Strains

Extreme temperatures, whether hot or cold, can affect CVT operation. For instance, cold climates might cause the transmission fluid to thicken, affecting its lubricating properties. Similarly, exposure to floodwaters or excessive moisture can introduce contaminants into the CVT, impacting its function.

Previous Repairs or Modifications

Variability in Repair Quality

Not all repair shops have the expertise to properly service or repair CVTs, especially those specific to Nissan vehicles. Improper repairs can introduce new issues or exacerbate existing ones.

Risks of Unauthorized Modifications

While some enthusiasts might modify their CVTs to achieve better performance or a different driving experience, such changes can sometimes lead to failures. Using non-standard parts or altering the CVT’s software settings without a deep understanding can lead to unexpected outcomes and potential damage.

Symptoms of CVT Failure

Transmission Slippage or Delay

Identification of Slippage

When a driver presses the accelerator, but the vehicle doesn’t respond immediately or accelerates unpredictably, it’s a sign of transmission slippage. This can feel as if there’s a delay between the gas pedal input and the vehicle’s movement.

Possible Reasons for Delay

Transmission delays might result from low transmission fluid, worn-out belts, or damaged pulleys within the CVT system. The sensation can be similar to driving a vehicle with a manual transmission and not releasing the clutch properly.

Unusual Noises (e.g., whining or rattling)

Whining Noises

A consistent whining noise, especially during acceleration, is a common symptom of CVT distress. It can indicate issues like low transmission fluid or a misaligned belt.

Rattling and Other Noises

Rattling or clunking sounds might be a result of damaged or loose components inside the CVT. It’s essential to differentiate these noises from typical engine sounds to ensure they’re not overlooked.

Overheating Warning Lights

Significance of the Warning Light

The overheating warning light on the dashboard signals that the CVT temperature has exceeded its safe operating range. Overheating can significantly reduce the CVT’s lifespan and lead to immediate failure.

Common Causes for Overheating

Extended periods of aggressive driving, towing heavy loads, or blocked cooling systems can all lead to CVT overheating. Regular maintenance is vital to prevent this issue.

Performance Reduction

Lack of Responsiveness

When a CVT begins to fail, the vehicle’s overall performance can degrade. The car might feel sluggish, lack power during acceleration, or struggle during uphill drives.

Impact on Fuel Efficiency

A malfunctioning CVT can also lead to decreased fuel efficiency. Since the transmission isn’t operating optimally, the engine has to work harder, consuming more fuel in the process.

Failure in Switching Gears

Symptoms of Gear Switching Issues

While CVTs don’t have traditional “gears” like manual or automatic transmissions, they do vary their ratios. If the CVT can’t adjust these ratios properly, it might feel like a gear “sticking” or the vehicle not accelerating as expected.

Relevance to Driving Conditions

In situations requiring rapid changes, such as merging onto highways or overtaking, an inability to “switch gears” can become especially noticeable. This limitation can compromise the safety and utility of the vehicle in demanding scenarios.

Preventive Measures and Maintenance

Regular Inspection and Fluid Changes

Benefits of Routine Inspection

Conducting regular CVT inspections can catch issues before they become major problems. Checking for leaks, damage, or worn-out components can help ensure the transmission’s longevity and performance.

The Need for Fluid Changes

Just as oil changes are crucial for engine health, regular transmission fluid changes are vital for CVTs. Over time, transmission fluid can degrade or become contaminated, so replacing it can prevent excessive wear and friction inside the CVT.

Using Manufacturer-Recommended Transmission Fluids

Ensuring Compatibility

Every CVT design has specific requirements, and using the manufacturer-recommended transmission fluid ensures optimal compatibility and performance. This fluid is formulated to meet the unique needs of the CVT, from lubrication to cooling.

Risks of Using Alternative Fluids

While some aftermarket fluids claim compatibility with multiple CVTs, using non-recommended types can lead to premature wear or even damage. It’s akin to putting the wrong type of fuel in a car; it might work temporarily, but long-term effects can be detrimental.

Avoiding Extreme Driving Conditions

Understanding CVT Limitations

CVTs are designed for efficiency and smoothness, not necessarily for extreme conditions. Consistently driving aggressively, towing heavy loads, or rapidly switching between acceleration and deceleration can strain the CVT.

Adapting Driving Habits

Being mindful of how one drives can go a long way in preserving the CVT’s health. For instance, allowing the car to warm up in cold conditions or avoiding heavy throttle inputs can reduce the stress on the transmission.

Installing Auxiliary Transmission Coolers

Role of Coolers in CVTs

Heat is a major enemy of CVTs, and auxiliary transmission coolers can help manage and reduce high temperatures. These coolers supplement the vehicle’s primary cooling system, offering additional capacity to dissipate heat.

Benefits of Reduced Temperatures

By maintaining the CVT at a more moderate temperature, an auxiliary cooler can prolong its life and prevent issues related to overheating. This is especially beneficial for drivers in hot climates or those who frequently engage in activities that strain the transmission, like towing.