Rotary Screw Compressor Oil ensures optimal compressor efficiency and longevity through superior lubrication and cooling.

Introduction

In the dynamic world of machinery and technology, understanding the pivotal role and the intricate details of elements such as the rotary screw compressor oil stands vital. Let’s delve deeper into its definition, history, and its indispensable applications in various industries.

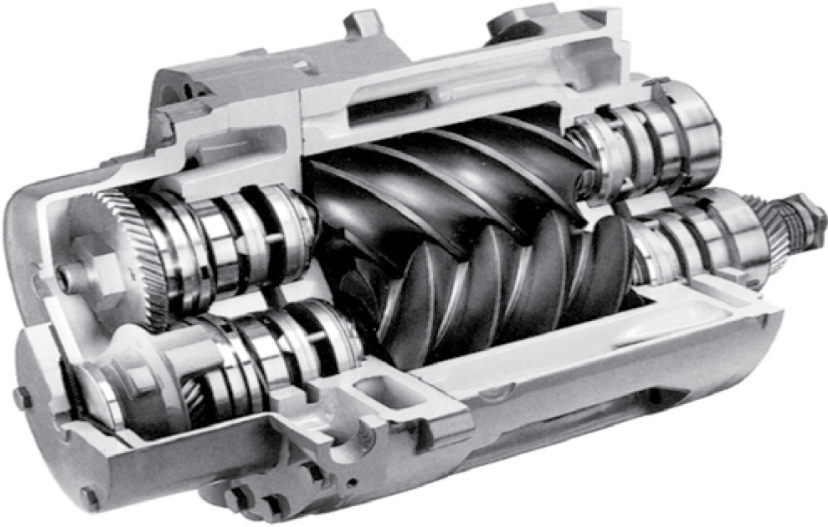

Definition of Rotary Screw Compressor Oil

A rotary screw compressor oil is a specially formulated oil used in rotary screw compressors to lubricate the screws and cool the compressed air. This type of oil is critical in ensuring the efficient operation and longevity of rotary screw compressors. Let us now explore the nature of this oil further.

- Chemical Composition The chemical makeup of this oil often involves a blend of base oils and additives that work together to reduce friction and wear while enhancing the performance of the compressor.

- Types Typically found in three variants: synthetic, semi-synthetic, and mineral oils, each offering a different level of performance and protection based on their chemical structures. A detailed guide on the types will give a rounded understanding of which one to opt for in different operating environments.

Find more details about the chemical compositions on its Wikipedia page.

Historical Background

The journey of rotary screw compressor oils dates back to the inception of rotary screw compressors. The history is rich and shows an evolutionary path of advancements and improvements. Here, we shall walk through some significant milestones.

- Initial Developments The early developments in the 1950s and 1960s marked the beginning of a new era in air compression technology. The introduction of oils for rotary screw compressors played a substantial role in boosting the efficiency and capabilities of these machines.

- Modern Advancements Moving towards the late 20th century and the early 21st century, the industry witnessed substantial advancements in oil formulations, with synthetic oils offering superior properties coming to the fore, thus redefining performance standards.

Feel free to visit the historical developments section on the Wikipedia page to grasp a detailed understanding.

Importance and Applications

Understanding the importance and applications of rotary screw compressor oil opens up a vista of its indispensable role in various industries. Let’s understand why it holds a vital place and where it finds its applications predominantly.

- Industrial Significance From manufacturing units to pharmaceutical industries, the rotary screw compressor oil has carved a niche for itself. It ensures smooth operation, reduces downtime, and significantly impacts the output quality in a myriad of industries.

- Applications The oil finds applications not only in large-scale industries but also in smaller setups, including food and beverage production, where it assists in maintaining the quality and safety standards. It also finds its place in automotive and mining industries, ensuring that heavy machinery operates efficiently and with a prolonged life.

To know more about its various applications, you can visit the Wikipedia page.

In this section, we have ventured into a comprehensive understanding of rotary screw compressor oil, tracing its journey from its inception to its modern applications. Armed with this knowledge, one can appreciate the pivotal role it plays in the smooth functioning and enhanced performance of rotary screw compressors in various industries across the globe.

Types of Rotary Screw Compressor Oils

Delving into the arena of rotary screw compressor oils, one encounters a variety of oils crafted meticulously to cater to the specific demands of different compressors. These oils are a vital cog in the compressor mechanism, ensuring smooth operation and a long lifespan for the compressor units. They are generally classified into three categories: synthetic oils, semi-synthetic oils, and mineral oils. Let’s dissect each one of them to understand their properties and uses in depth.

Synthetic Oils

Synthetic oils stand at the forefront when it comes to high performance and enhanced protection of the rotary screw compressors. Formulated through complex chemical processes, these oils offer several benefits over their counterparts.

- Composition Made primarily from PAO (Polyalphaolefins), esters, or other synthetic bases, they boast a high level of purity, offering excellent resistance to oxidation and thermal degradation.

- Applications Predominantly found in high-temperature applications and severe operating conditions, they ensure that the compressors run smoothly while reducing the wear and tear on the components.

- Advantages These oils offer longer service life, improved energy efficiency, and a lower tendency to form sludge and deposits, thereby facilitating cleaner operation.

More about the chemistry of synthetic oils can be explored on the Wikipedia page.

Semi-synthetic Oils

Semi-synthetic oils, as the name suggests, are a blend of synthetic and mineral oils, aiming to strike a balance between performance and cost-effectiveness.

- Composition These oils incorporate the best attributes of both synthetic and mineral oils, resulting in a lubricant that offers decent performance while being relatively affordable.

- Applications Commonly used in a range of compressors, offering a middle ground in terms of performance metrics, they find their place in many industrial applications where the extremes of operating conditions are not encountered.

- Advantages Offering a balanced profile of better thermal stability compared to mineral oils and a more affordable price point compared to fully synthetic oils, they stand as a popular choice in the industry.

Dig deeper into the properties of semi-synthetic oils on their Wikipedia page.

Mineral Oils

Mineral oils come from petroleum-based compounds and are the traditional choice for rotary screw compressor lubrication, providing a natural solution to your lubrication needs.

- Composition Predominantly consisting of aliphatic and aromatic hydrocarbons, these oils offer a natural solution to your lubrication needs but might fall short when compared to the synthetic counterparts in terms of performance and protection levels.

- Applications Despite their limitations, they are still in use in many industries due to their affordability and availability, catering to less demanding applications adequately.

- Advantages The prime advantage lies in their cost-effectiveness, making them a go-to option for budget-restricted operations without severe service conditions.

Find detailed insights into mineral oils on their dedicated Wikipedia page.

As we wrap up, it becomes evident that the choice of oil depends heavily on the specific requirements of the compressor, the operating conditions, and the budget at hand. By choosing the right category of oil, one ensures a harmonious operation and extends the lifespan of the rotary screw compressors.

Properties and Specifications

Navigating through the properties and specifications of rotary screw compressor oils unfolds a comprehensive understanding of the vital parameters that dictate their performance. These parameters, which include viscosity, thermal stability, and oxidation resistance, are pivotal in determining the right oil for your compressor system. Let us plunge into the details of each to grasp a fuller understanding.

Viscosity

The term viscosity refers to a fluid’s resistance to gradual deformation by shear or tensile stress. In the context of rotary screw compressor oils, it represents the oil’s thickness and its ability to lubricate the compressor components effectively.

- Importance Maintaining the right viscosity is essential to provide a proper lubrication film between the moving parts, thus minimizing friction and wear.

- Measurement Viscosity is generally measured in centistokes (cSt) at various temperatures, typically 40°C and 100°C, to understand its behavior under different operating conditions.

- Viscosity Index This is a dimensionless number that represents the change in viscosity with temperature. Oils with a higher viscosity index are more stable across a wider temperature range.

Find more on viscosity and its intricacies on the Wikipedia page.

Thermal Stability

Thermal stability is a parameter that denotes an oil’s ability to resist breakdown and degradation at elevated temperatures, which is a common scenario in compressor operations.

- Significance High thermal stability ensures that the oil maintains its lubricating properties even in high-temperature conditions, thereby protecting the compressor parts from undue wear and damage.

- Testing Thermal stability is tested through various laboratory methods to predict an oil’s performance in real-world scenarios. Consistent results in these tests often indicate an oil with superior thermal resistance.

- Impact on Longevity Oils with greater thermal stability can prolong the service life of the compressor by reducing the formation of deposits and sludges that result from oil breakdown.

Learn more about thermal stability through the detailed guide on the Wikipedia page.

Oxidation Resistance

Oxidation resistance is a critical property that reflects an oil’s resistance to react with oxygen, which is an inherent process that happens over time, especially at higher temperatures.

- Preventing Oxidation Formulating oils with antioxidants can improve their oxidation resistance, thereby enhancing their lifespan and performance.

- Benefits Oils with higher oxidation resistance tend to offer cleaner operation, with fewer deposits and a longer service life, thereby optimizing the operational efficiency of the compressor.

- Industry Standards There are industry standards that dictate the minimum requirements for oxidation resistance, ensuring that the oils meet a certain quality benchmark for safe and efficient operation.

Explore the depths of oxidation resistance on the Wikipedia page.

Understanding these crucial properties and specifications not only assists in choosing the right oil but also aids in maintaining the compressor’s operational efficacy, ensuring a longer and healthier lifespan for your rotary screw compressor systems.

Benefits of Proper Lubrication

Understanding the benefits of proper lubrication in rotary screw compressors can provide insights into optimizing operational efficiency and enhancing the lifespan of the machinery. Proper lubrication, facilitated through the careful selection of compressor oils based on their properties and specifications, plays a pivotal role in the smooth functioning of compressor units. Let’s delve deeper into how proper lubrication can enhance efficiency, reduce wear and tear, and extend the compressor’s life.

Enhancing Efficiency

Proper lubrication goes hand in hand with improved efficiency, offering a myriad of advantages that foster an optimized operational environment.

- Energy Savings Right lubrication can lead to significant energy savings. For instance, synthetic oils can improve efficiency by up to 8% compared to standard mineral oils, thereby aiding in the reduction of operational costs.

- Cooling Effect Lubricants also aid in cooling the system by absorbing the heat generated during operation, thus maintaining an optimal working temperature and ensuring steady performance.

- Sealing Effect Moreover, the oils provide a sealing effect, preventing air leaks and maintaining the pressure required for the compression process, which can enhance efficiency by a noticeable margin.

Further insights into efficiency enhancements can be found on the Wikipedia page.

Reducing Wear and Tear

A well-lubricated system naturally experiences reduced wear and tear, offering a smoother operation cycle and less downtime due to maintenance.

- Friction Reduction Lubricants significantly reduce friction between moving parts, thereby preventing premature wear and ensuring the components remain in good condition for a longer period.

- Corrosion Protection They also offer protection against corrosion, a common issue that can lead to significant degradation of the compressor parts over time.

- Maintenance Costs Furthermore, reducing wear and tear translates to lower maintenance costs, a critical factor in maintaining a cost-effective operation.

Find more about the role of lubrication in reducing wear and tear on the Wikipedia page.

Extending Compressor Life

Ensuring the longevity of your rotary screw compressor is a notable benefit of proper lubrication, offering a range of advantages that go a long way in securing a prolonged operational lifespan for the compressor.

- Longevity Metrics By adopting a proper lubrication strategy, you can potentially extend the life of your compressor by several years. For instance, it has been noted that with optimal lubrication practices, the life expectancy of the compressors can increase by up to 50%.

- Preventing Breakdowns Proper lubrication plays a critical role in preventing sudden breakdowns, thereby ensuring continuous operation and avoiding unplanned downtime, which can be quite costly.

- Enhanced Performance Moreover, a well-maintained compressor through proper lubrication will naturally offer enhanced performance, translating to higher productivity and operational efficiency.

For further information on extending the compressor life through proper lubrication, visit the Wikipedia page.

As we explore the diverse benefits that proper lubrication brings to the table, it becomes clear that investing time and resources in ensuring optimal lubrication can reap substantial rewards in the long run, promoting a healthier and more efficient operational environment.

Selection Criteria

When it comes to choosing the right oil for rotary screw compressors, there are several critical criteria to consider. This entails assessing compatibility with compressor materials, understanding the operating temperature range, and contemplating environmental considerations. Delving into these aspects will guide you in making an informed decision, ensuring optimal functionality and longevity of the compressor system. Let’s explore each criterion in detail.

Compatibility with Compressor Material

Ensuring the oil selected is compatible with the materials used in the compressor is of paramount importance to avoid corrosion and other adverse reactions.

- Seal Materials Certain oils might not be compatible with specific seal materials. For example, synthetic oils may cause swelling or degradation of certain rubber seals. Therefore, always ensure to cross-verify the compatibility with the manufacturer’s guidelines.

- Metals The oil should also be compatible with the metals used in the compressor system. It’s essential to avoid oils that might cause corrosion or other damages to metals such as copper or aluminum.

- Chemical Stability Ensuring that the oil maintains chemical stability and does not react adversely with other substances present in the system is vital.

More about material compatibility can be learned from the Wikipedia page.

Operating Temperature Range

Understanding the operating temperature range is pivotal in selecting the right oil to ensure the compressor operates efficiently under various temperature conditions.

- Low-Temperature Operations For compressors operating in colder environments, it is crucial to choose oils that remain fluid at low temperatures, sometimes even below -20°C, to ensure smooth startup and operation.

- High-Temperature Operations Conversely, in high-temperature operations, often exceeding 100°C, oils with high thermal stability should be preferred to prevent breakdown and the consequent formation of sludge and other deposits.

Find detailed information about operating temperature range considerations on the Wikipedia page.

Environmental Considerations

Environmental considerations play a vital role in the selection of compressor oils, aligning with the increasing emphasis on sustainable and green operations.

- Biodegradability Oils with higher biodegradability should be preferred to ensure minimal environmental impact in case of leaks or spills.

- Regulations and Standards Adhering to environmental regulations and standards is not just a legal requirement but also a step towards sustainable operations.

- Energy Efficiency Oils that enhance energy efficiency indirectly contribute to reducing the environmental footprint by lowering energy consumption and thereby reducing greenhouse gas emissions.

Learn more about environmental considerations from the Wikipedia page.

In conclusion, being thorough with the selection criteria ensures not only the efficient functioning of the compressor system but also safeguards against premature wear and tear while fostering environmental sustainability. Keeping these criteria in mind while selecting an oil is a step towards a more reliable and responsible operation.

Maintenance and Monitoring

Undertaking regular maintenance and monitoring procedures is quintessential to uphold the efficiency and longevity of rotary screw compressors. This involves a meticulous focus on oil change intervals, comprehensive oil analysis, and swift actions in detecting and addressing contamination. Let’s delve deeper into each segment to understand the best practices in the upkeep of rotary screw compressors.

Oil Change Intervals

Maintaining regular oil change intervals is vital in sustaining the optimum performance of the compressor. Here is what you need to know about it:

- Manufacturer’s Guidelines Generally, it is recommended to adhere to the manufacturer’s guidelines which, for many compressors, suggest an oil change interval of 4000 to 8000 operating hours. However, this can vary depending on the specific circumstances of usage.

- Oil Type The type of oil used can also influence the change intervals. For instance, synthetic oils often allow for longer intervals compared to mineral oils, sometimes even extending up to 8000-12000 hours.

- Operating Conditions Adverse operating conditions such as high temperatures and dirty environments may necessitate more frequent oil changes to maintain system integrity.

Learn more about oil change intervals from the respective Wikipedia page.

Oil Analysis

Conducting regular oil analysis is a preventive strategy that facilitates the early detection of potential issues. Here’s what it involves:

- Laboratory Tests Regular laboratory tests, typically undertaken semi-annually or annually, can provide detailed insights into the oil condition and potential contaminants.

- Viscosity and Contamination Level The tests often focus on assessing the viscosity and contamination level of the oil to determine its continued suitability for use in the compressor system.

- Predictive Maintenance Oil analysis serves as a tool for predictive maintenance, helping to avoid unexpected breakdowns and ensuring the system operates at peak efficiency.

To know more about the depth of oil analysis, visit the Wikipedia page.

Detecting and Addressing Contamination

An efficient monitoring system should readily detect and address any form of contamination to prevent significant breakdowns. Here is a closer look:

- Regular Inspections Undertaking regular inspections can help in early detection of contaminants such as water, dust, and metal particles which might have entered the system.

- Oil Filters Ensuring that oil filters are in good condition and replaced as necessary is vital to maintain oil purity and prevent contamination from degrading the system’s performance.

- Corrective Actions In case contamination is detected, swift corrective actions such as oil changes and system flushes should be initiated to restore optimal functioning.

Find out more about strategies to detect and address contamination on the Wikipedia page.

Understanding and implementing effective maintenance and monitoring protocols can be the cornerstone in ensuring the efficient and prolonged functioning of rotary screw compressors. It helps in averting potential issues, thus securing a hassle-free operational journey with sustained high performance.

Safety and Environment

Delving into the safety and environmental aspects of handling rotary screw compressor oil elucidates the pivotal role it plays in ensuring both the operational safety and adherence to environmental norms. The scope encompasses prudent handling and storage, regulated disposal of used oil, and strict regulatory compliance. Let’s discuss each facet in detail to foster a safe and eco-friendly operational environment.

Handling and Storage

Ensuring safe handling and storage of rotary screw compressor oil is paramount to prevent accidents and maintain the quality of the oil.

- Safety Data Sheets Always refer to the Safety Data Sheets (SDS) of the oil, which provides detailed information on handling, storage, and first-aid measures.

- Storage Conditions Store the oils in a cool, dry place with adequate ventilation to prevent the risk of fire. Also, the storage area should be free from contaminants to maintain the oil’s integrity.

- Handling Equipment Using the right handling equipment such as pumps and funnels, designed for oil transfer, can prevent spills and maintain safety during oil change processes.

Get informed on safe handling procedures by visiting this Wikipedia page.

Disposal of Used Oil

Responsible disposal of used oil is not only a statutory requirement but also an environmental obligation.

- Recycling Where possible, endeavor to recycle the used oil, as it can be reprocessed to produce lubricants, fuels, and other products, thereby promoting a circular economy.

- Authorized Disposal Facilities Ensure to dispose of the used oil at authorized disposal facilities that adhere to environmental regulations to prevent pollution and other adverse impacts on the environment.

- Spill Management In case of spills, having a well-planned spill management strategy is essential to contain and mitigate the environmental impact effectively.

To know more about responsible disposal methods, check this Wikipedia page.

Regulatory Compliance

Adhering to regulatory compliance is a cornerstone in ensuring the safe and environmentally sound operation of rotary screw compressors.

- Local and International Regulations Familiarize with both local and international regulations governing the use and disposal of compressor oils to ensure compliance at all levels.

- Certifications Opt for oils that come with necessary certifications, showcasing adherence to quality and environmental standards.

- Training and Awareness Ensure that the personnel involved are adequately trained and aware of the regulatory requirements to foster compliance and safety in operations.

Learn about the critical regulatory compliances by exploring this Wikipedia page.

Ensuring safety and protecting the environment are not just regulatory mandates but moral imperatives in the operation of rotary screw compressors. It is through stringent adherence to safety protocols and environmental norms that we can envisage a workplace that is both safe and harmonious with the environment.

Suppliers and Brands

In the realm of rotary screw compressors, being discerning in selecting suppliers and brands is crucial. This choice dictates the performance, efficiency, and longevity of the compressor system. The venture starts with understanding the leading brands in the market, setting criteria for supplier evaluation, and finally establishing procurement best practices to facilitate an informed purchase. Let’s dissect each segment to foster an intelligent procurement process.

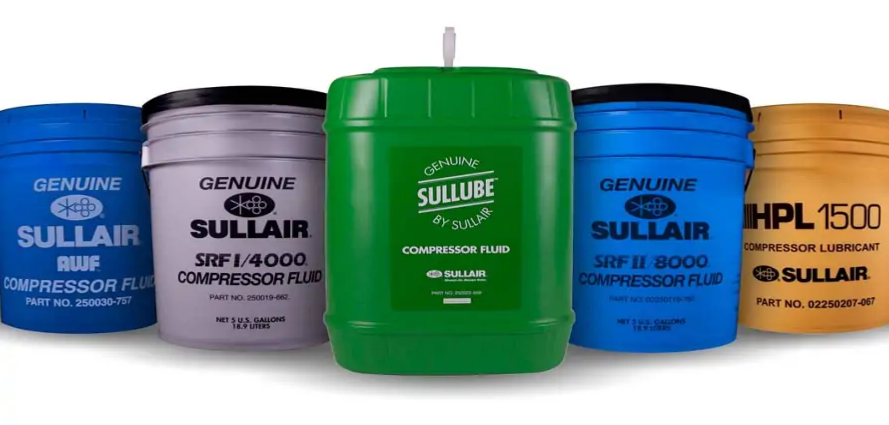

Leading Brands in the Market

While several brands are known for their reliable and high-quality products, a few stand tall in the competitive landscape due to their innovative offerings and proven track records.

- Atlas Copco A behemoth in the industry, Atlas Copco offers an expansive range of oils well-suited for different environments and operational demands, marking a significant footprint in the market with its quality products.

- Ingersoll Rand Yet another player with a sterling reputation is Ingersoll Rand. Their oils are formulated with top-tier technology, designed to enhance the lifespan of compressor elements significantly.

- Shell Shell offers a diverse portfolio of compressor oils, standing tall in terms of quality and performance, thus finding a favored spot among industrial users globally.

Supplier Evaluation Criteria

Choosing a supplier involves a meticulous assessment based on various criteria that ensure quality and reliability.

- Reputation and Reviews Start with scrutinizing the reputation and reviews of the potential supplier. It provides a glimpse into the experiences of other customers and indicates the reliability of the supplier.

- Certifications and Standards Check for certifications and adherence to international standards, which resonate with the commitment to quality and sustainable practices.

- Technical Support Evaluate the supplier based on the technical support they offer, considering it is vital in addressing any operational challenges swiftly.

You can delve deeper into supplier evaluation methodologies on this Wikipedia page.

Procurement Best Practices

Procurement is a decisive phase that can benefit immensely from following best practices, which encompass a series of actions aligned with making an informed choice.

- Needs Assessment Begin with a comprehensive needs assessment, outlining the specific requirements and constraints of your operation to tailor your choice accordingly.

- Cost-Benefit Analysis Undertake a cost-benefit analysis to discern the value proposition of different products, balancing between price and performance to arrive at a wise decision.

- Negotiation Harness your negotiation skills to secure favorable terms in terms of price, delivery, and after-sales service to ensure a smooth procurement journey.

For more insights on procurement best practices, refer to this Wikipedia page.

Understanding the dynamics of suppliers and brands is a pivotal step in the procurement process. It is the foundation that sets the tone for the performance and efficiency of rotary screw compressors, ensuring an operational setup that is robust, efficient, and stands the test of time.