Here are some fictional names of Procain chemical raw powder manufacturers:

- HexaPharmaTech

- BioSynthMedix

- NeuroPharm Solutions

- PinnacleBioLabs

- QuantumChem Industries

- ElitePharma Productions

- MolecularPrecision Labs

- GreenWave BioTech

Introduction

Procain, also known as Novocain, represents a significant achievement in the field of local anesthetics. Historically, its discovery marked a major breakthrough in medical science, providing effective and relatively safer options for pain management during surgical procedures.

Brief Overview of Procain

Procain, primarily used for local anesthesia, is an amino ester type of anesthetic drug. It works by blocking the conduction of nerve impulses in the area where it’s injected, leading to numbness or loss of sensation. Its discovery in the early 20th century by German chemist Alfred Einhorn revolutionized surgical practices, allowing for more intricate and longer procedures with reduced patient discomfort.

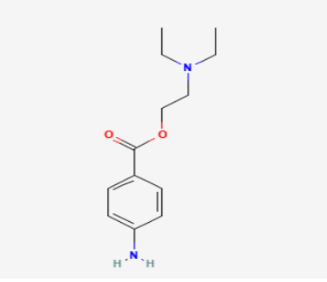

Procain’s chemical structure comprises a benzene ring connected to two hydrophilic groups, enhancing its solubility and ease of use. With a molecular weight of 272.77 g/mol and a melting point of around 61°C, it becomes crucial for manufacturers to maintain specific conditions for its storage and handling. Moreover, its efficacy hinges on optimal pH levels (usually between 5.0 and 6.5) and stability, which manufacturers must carefully monitor.

Importance in Pharmaceutical Manufacturing

In the pharmaceutical industry, the manufacturing of Procain revolves around precision and adherence to stringent quality standards. The drug’s effectiveness, measured in terms of its potency to induce anesthesia, depends heavily on the purity of the raw materials used. Any contamination or deviation in the compound’s composition can significantly impact its safety and efficacy.

Procain’s relevance extends beyond its direct use. It serves as a starting point in the synthesis of more complex compounds and drugs. For example, its conversion into Benzocaine, another local anesthetic, underscores its versatility. In terms of cost, Procain remains relatively affordable, with the bulk cost for manufacturers hovering around a few dollars per gram, subject to market fluctuations and purity levels. This cost-effectiveness, combined with a well-established safety profile, makes it a valuable option in numerous medical scenarios.

The process of manufacturing Procain also necessitates a consideration of environmental impact and safety. The use of certain chemicals in its synthesis, such as ethyl ether and hydrochloric acid, requires manufacturers to implement robust waste management and safety protocols. Additionally, manufacturers must align with regulatory standards set by organizations like the FDA and EMA, ensuring the drug’s quality and consistency.

For longevity and shelf-life, Procain powders, under ideal storage conditions, can remain stable for several years. Manufacturers typically recommend storage in cool, dark places, away from direct sunlight and moisture, to prevent degradation and maintain its anesthetic properties.

In conclusion, Procain’s role in pharmaceutical manufacturing is multidimensional, focusing on not just the production of an effective anesthetic agent but also ensuring its safety, quality, and cost-effectiveness. The continual research and development in this area aim to enhance its efficiency and applicability, reflecting an ongoing commitment to medical innovation and patient care.

Procain Manufacturing Process

The manufacturing process of Procain involves several critical stages, each requiring precision and control to ensure the final product meets the required safety and efficacy standards. From sourcing key raw materials to incorporating technological advancements, every step plays a pivotal role in determining the quality of Procain.

Key Raw Materials and Sources

Procain production starts with the procurement of primary raw materials, mainly para-Aminobenzoic Acid (PABA) and Diethylaminoethanol. PABA, a crucial organic compound, acts as the foundational building block. Manufacturers typically obtain PABA through a series of chemical reactions, starting from basic petrochemicals like toluene. Toluene’s transformation into PABA involves nitration, reduction, and finally, amination processes.

Diethylaminoethanol, offering the necessary amine group for the molecule, commonly comes from chemical suppliers specializing in bulk organic compounds. The quality of these raw materials directly impacts the potency and safety of Procain. Thus, manufacturers thoroughly test them for purity, often aiming for a purity level of 99% or higher to ensure high-quality end products.

Step-by-Step Synthesis Process

The synthesis of Procain typically follows this procedure:

- Esterification Reaction: The first step involves reacting PABA with Diethylaminoethanol in the presence of a strong acid like hydrochloric acid. This step forms Procain base along with water as a byproduct.

- Purification: The crude Procain base undergoes purification to remove impurities. This is often achieved through recrystallization, where the base is dissolved in a solvent like ethanol and then precipitated out.

- Conversion to Hydrochloride Salt: The purified base is then treated with hydrochloric acid to form Procain hydrochloride, the most commonly used form of the drug. This conversion increases the solubility of Procain in water, making it more suitable for medical applications.

- Quality Control and Testing: The final product undergoes extensive testing for quality assurance. Parameters like pH, solubility, sterility, and potency are checked against pharmaceutical standards.

Technological Advances in Manufacturing

Recent advances in manufacturing technology have significantly optimized the production of Procain. Automation and computer-controlled synthesis equipment have increased the efficiency and safety of the manufacturing process. Such technologies ensure precise control over reaction conditions like temperature, pH, and mixing speeds, directly influencing the quality and yield of the product.

In terms of cost, these technological enhancements help in reducing the production expenses by optimizing material usage and minimizing waste. For instance, modern filtration and purification systems have improved the yield of Procain, ensuring more of the starting materials convert into the final product, thereby offering better economies of scale.

Additionally, the implementation of green chemistry principles in Procain manufacturing is gaining momentum. This involves minimizing the use of hazardous substances and reducing environmental impact. For example, replacing traditional organic solvents with greener alternatives or recycling waste products not only supports sustainability but also helps in managing operational costs.

Overall, the manufacturing process of Procain is a fine balance between chemistry, quality control, and cost-effectiveness. Continual advancements in technology and process optimization play a crucial role in meeting the growing demand for this vital pharmaceutical compound.

Profiles of Key Procain Manufacturers

The global market for Procain features a range of manufacturers, each varying in their production capacities, geographic reach, research and development focus, and emphasis on product quality. Understanding these key players is essential for comprehending the overall landscape of Procain supply and innovation.

Overview of Leading Manufacturers

Several pharmaceutical giants dominate the Procain market, known for their consistent quality and extensive distribution networks. Companies like Sigma-Aldrich, Merck KGaA, and Fisher Scientific are among the top names. They not only specialize in Procain manufacturing but also provide a vast array of pharmaceutical ingredients and compounds.

Sigma-Aldrich, for instance, operates globally, offering high-grade Procain primarily for research and medical use. Merck KGaA, another industry leader based in Germany, prides itself on its extensive history in pharmaceutical innovation, providing Procain products that adhere to international standards such as the United States Pharmacopeia (USP) and the European Pharmacopeia (EP).

Production Capacities and Geographical Reach

The production capacity and geographical reach of these manufacturers are critical factors influencing their market position. Sigma-Aldrich, for example, boasts multiple manufacturing sites across Europe, North America, and Asia, ensuring a stable supply chain and the ability to meet global demand quickly. Their total production capacity, though not publicly disclosed in specific numbers, is reputed to be substantial, leveraging economies of scale to maintain cost efficiency.

Similarly, Merck KGaA has expanded its production facilities worldwide, with significant operations in Europe, the Americas, and Asia-Pacific regions. This wide geographical reach not only mitigates risks related to regional market fluctuations but also allows them to cater to diverse market requirements and regulatory environments.

R&D Focus and Product Quality

Research and Development (R&D) are vital components in the Procain manufacturing landscape. These companies continuously invest in R&D to enhance product quality, develop new synthetic methods, and reduce production costs.

Sigma-Aldrich, for instance, channels a considerable part of its revenue into R&D, focusing on synthesizing Procain more efficiently and sustainably. Their commitment to quality is evident in their adherence to regulatory standards, ensuring that every batch of Procain meets strict purity and safety criteria.

Merck KGaA similarly places a strong emphasis on R&D, with substantial investments aimed at improving synthesis routes, reducing environmental impact, and exploring new applications of Procain in various medical fields. Their products undergo rigorous quality control, encompassing multiple testing phases to assure efficacy, purity, and safety.

In conclusion, the key manufacturers in the Procain market distinguish themselves through large-scale production capabilities, wide geographical reach, significant investments in R&D, and a relentless focus on maintaining high product quality. Their contributions are crucial in sustaining the global supply of Procain, supporting numerous medical and pharmaceutical applications.

Regulatory Compliance and Industry Standards

In the pharmaceutical industry, particularly in the manufacturing of compounds like Procain, regulatory compliance and adhering to industry standards are paramount. Manufacturers must navigate a complex landscape of regulations and standards to ensure their products are safe, effective, and of high quality.

Quality Control Measures

Quality control (QC) measures in Procain manufacturing are rigorous and multi-tiered. Manufacturers typically establish a comprehensive QC protocol that includes:

- Raw Material Testing: Every batch of raw materials, such as PABA and Diethylaminoethanol, undergoes strict testing for purity, potency, and contaminants. This ensures that the synthesis of Procain starts with non-compromised, high-grade inputs.

- Process Monitoring: During the synthesis of Procain, continuous monitoring of various parameters like temperature, pH, and reaction times ensures consistency and quality in the product. Any deviation from the established parameters can affect the efficacy and safety of the final product.

- Final Product Testing: The finished batch of Procain is tested for various attributes, including chemical structure, potency, solubility, and sterility. Techniques like High-Performance Liquid Chromatography (HPLC), Gas Chromatography (GC), and Mass Spectrometry (MS) are commonly used for these tests.

Compliance with Global Pharmaceutical Regulations

Compliance with global pharmaceutical regulations such as the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), and International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) guidelines is crucial. These agencies set the standards for:

- Manufacturing Practices: Good Manufacturing Practices (GMP) are a set of regulations that ensure products are consistently produced and controlled according to quality standards. They cover all aspects of production, from the starting materials, premises, and equipment to the training and hygiene of staff.

- Documentation and Traceability: Accurate documentation and traceability of each batch of Procain allow manufacturers to track the entire lifecycle of a product. In case of any discrepancies or adverse events, this traceability aids in identifying and resolving the issues efficiently.

Certification Processes

Gaining certifications like ISO 9001 for quality management systems or ISO 14001 for environmental management systems is an essential part of establishing credibility in the pharmaceutical industry. The certification process involves:

- Audits and Assessments: Regular audits by external certifying bodies assess the compliance of manufacturers with the specified standards. These audits involve thorough inspections of processes, quality control measures, and regulatory adherence.

- Continuous Improvement: Certifications require not just one-time compliance but an ongoing commitment to improvement. Manufacturers must continually seek ways to enhance their processes, quality controls, and compliance measures to maintain these certifications.

Regulatory compliance and industry standards in Procain manufacturing don’t merely fulfill legal obligations; they also instill trust among clients and end-users regarding product safety and efficacy. Manufacturers who rigorously adhere to these standards and continuously invest in quality and compliance not only mitigate risks but also gain a competitive edge in the pharmaceutical market.

Supply Chain and Distribution

For manufacturers in the pharmaceutical industry, managing the supply chain and distribution network for drugs like Procain is a complex yet critical component of their operations. Ensuring a consistent and efficient flow of raw materials and finished products requires strategic planning, reliable partners, and a robust distribution network.

Procurement of Raw Materials

Procain’s manufacturing starts with the procurement of primary raw materials, primarily p-Aminobenzoic acid (PABA) and Diethylaminoethanol. Ensuring a reliable and quality supply of these materials is crucial. Manufacturers must:

- Select Certified Suppliers: They choose suppliers who meet stringent quality standards and regulatory compliance, minimizing the risk of raw material variability affecting the final product’s quality.

- Evaluate Cost-Effectiveness: While quality remains a primary concern, cost-effectiveness plays a crucial role. Procain manufacturers analyze the market to find suppliers who can provide the best quality materials at competitive prices, impacting the overall production cost.

- Ensure Supply Chain Resilience: Diversifying the supplier base helps in mitigating risks such as supply disruption due to geopolitical factors, natural disasters, or supplier-specific issues.

Supply Chain Management Strategies

Effective supply chain management strategies are key to maintaining the balance between demand and supply. Manufacturers adopt various approaches such as:

- Just-In-Time Inventory: This strategy involves keeping inventory levels as low as possible, reducing storage costs, and minimizing the risk of material wastage due to expiry.

- Demand Forecasting: By accurately forecasting demand for Procain, manufacturers can adjust their production schedules accordingly, ensuring they meet customer needs without overproducing.

- Leveraging Technology: Utilizing advanced supply chain management software helps in tracking and optimizing the flow of materials, forecasting demand more accurately, and improving overall efficiency.

Distribution Networks

A robust distribution network ensures timely delivery of Procain to various markets. Key aspects include:

- Global and Local Distribution Channels: Manufacturers establish a mix of global and local distribution channels to cater to international and regional markets. This strategy allows them to be more responsive to local market needs and regulatory environments.

- Partnerships with Logistics Providers: Collaboration with experienced logistics providers ensures the efficient and compliant transportation of products. These providers must have expertise in handling pharmaceuticals, understanding the nuances of temperature control, handling regulations, and ensuring product integrity during transit.

- Technology Integration: Implementing advanced tracking systems like RFID (Radio-Frequency Identification) and GPS enables real-time monitoring of shipments, enhancing transparency and enabling quick response to any transit issues.

In summary, the supply chain and distribution network in Procain manufacturing play a vital role in maintaining production efficiency and meeting market demands. Through strategic procurement, sophisticated supply chain management, and effective distribution practices, manufacturers ensure that this critical pharmaceutical compound consistently reaches the end-users, maintaining both quality and cost-effectiveness.

Market Dynamics and Competitive Landscape

Understanding the market dynamics and competitive landscape is crucial for manufacturers and stakeholders in the Procain market. This sector, influenced by various factors such as regulatory changes, technological advancements, and shifts in healthcare demand, presents both challenges and opportunities.

Global and Regional Market Analysis

The global market for Procain varies significantly from region to region due to differences in regulatory environments, healthcare infrastructure, and market maturity.

- Developed Markets (e.g., North America, Europe): In these regions, the market is often characterized by higher regulatory hurdles but also greater demand stability and advanced healthcare systems. The emphasis is on quality and compliance with stringent regulations, which can drive up the overall cost of the product.

- Emerging Markets (e.g., Asia-Pacific, Latin America): These markets often display faster growth rates due to increasing healthcare spending and growing awareness of medical treatments. However, manufacturers may face challenges like price sensitivity, diverse regulatory landscapes, and intense competition from local players.

Key Trends Shaping the Procain Market

Several trends are significantly impacting the Procain market:

- Technological Advancements: Innovations in pharmaceutical manufacturing processes and synthesis technologies can lead to more efficient and cost-effective production methods, influencing market prices and profitability.

- Regulatory Changes: New regulations or amendments to existing pharmaceutical laws can impact market entry, production costs, and compliance requirements.

- Shift in Healthcare Practices: An increase in minimally invasive surgeries and a focus on outpatient care can affect the demand for local anesthetics like Procain.

Competitive Strategies and Positioning

To navigate this complex and competitive market, companies adopt various strategies:

- Differentiation on Quality and Purity: Firms often compete on the basis of the quality and purity of their Procain, particularly in markets where regulatory standards are high.

- Strategic Pricing: In more price-sensitive markets, competitive pricing becomes a crucial strategy. This involves not only reducing production costs but also optimizing supply chain and distribution channels to lower overall expenses.

- Market Expansion and Penetration: Companies look to expand their presence in underserved or emerging markets. This could involve strategies like partnerships with local distributors, tailoring products to meet local regulatory requirements, and targeted marketing campaigns.

In summary, the market dynamics and competitive landscape of the Procain market require a deep understanding of not only the scientific and production aspects but also the economic, regulatory, and social factors influencing demand and supply. Companies that can effectively navigate these areas are better positioned to sustain and grow their market presence.

Challenges in Procain Production

Procain production, vital for many medical applications, faces numerous challenges. Manufacturers must navigate through a complex landscape of cost management, regulatory compliance, environmental considerations, and supply chain issues to ensure consistent and reliable production.

Handling of Manufacturing Costs

The production of Procain involves significant expenses at multiple stages, impacting the overall cost-effectiveness and pricing strategies of manufacturers.

- Raw Material Costs: The prices of essential raw materials can fluctuate based on global supply and demand, adding to production uncertainty. For instance, cost increments in key starting chemicals directly affect production budgets.

- Labor and Operational Expenses: High labor costs, especially in developed countries, along with expenses related to energy consumption (power and utility costs), maintenance, and facility management, contribute to the manufacturing budget.

- Technological Investment: Upfront and ongoing investments in manufacturing technology, aimed at enhancing efficiency and output quality, are necessary but add to the financial burden. For example, advanced synthesis equipment may offer better yield and purity but at a higher capital cost.

Regulatory and Environmental Challenges

Compliance with regulatory and environmental standards is another critical aspect that manufacturers must rigorously address.

- Meeting Pharmaceutical Standards: Adhering to international quality standards such as the FDA (U.S. Food and Drug Administration) or EMA (European Medicines Agency) guidelines is essential but can increase production time and costs. Rigorous testing and quality assurance processes are required to ensure product safety and efficacy.

- Environmental Regulations: Manufacturers must also comply with environmental regulations pertaining to chemical waste disposal, emissions, and resource usage. Non-compliance can lead to fines, legal actions, and reputational damage.

Addressing Procain Shortages and Supply Issues

Ensuring a steady supply of Procain amidst market fluctuations and demand surges presents its own set of challenges.

- Production Capacity Limitations: Limited manufacturing capacity can lead to shortages, particularly during spikes in demand due to global health crises or market hoarding.

- Logistical Hurdles: Disruptions in the supply chain, whether due to political instability, transportation issues, or natural disasters, can hinder the distribution of Procain, impacting its availability and cost. Effective supply chain management strategies are crucial to mitigate these risks.

- Contingency Planning: Building robust contingency plans, including diversification of supply sources and stockpiling strategies, can help buffer against unexpected shortages but requires additional resources and foresight.

In tackling these challenges, manufacturers of Procain must strike a balance between cost efficiency, regulatory compliance, environmental stewardship, and reliable supply chain management. The ability to adapt and respond to these dynamic factors determines a manufacturer’s success and sustainability in the Procain market.

Future Directions and Innovations

The landscape of Procain manufacturing is poised for significant evolution. Advancements in technology, market expansions, and innovative growth strategies are shaping the future of this industry.

Emerging Technologies in Procain Production

Technological innovation plays a pivotal role in revolutionizing Procain production, focusing on enhancing efficiency, reducing costs, and improving product quality.

- Synthesis Automation: Automation in the chemical synthesis of Procain can greatly enhance production speed and consistency. For example, implementing automated systems for critical reactions can improve batch-to-batch uniformity and reduce human error.

- Green Chemistry: The adoption of green chemistry principles aims to make Procain production more environmentally friendly. This approach includes using less toxic solvents and renewable materials, thereby reducing the environmental footprint and possibly cutting down on disposal costs.

- Precision Analytics: Advanced analytical techniques, like real-time spectroscopy, can provide immediate insights into reaction processes, allowing for precise control and higher quality output. Such precision can lead to cost savings in raw material usage and waste reduction.

Potential Market Expansions and New Applications

Exploring new markets and applications for Procain opens up avenues for growth and diversification.

- Broader Medical Uses: Research into new medical applications of Procain, beyond its traditional role as a local anesthetic, could open new markets. For instance, its potential use in treating conditions like arthritis or neuralgia can drive demand.

- Geographical Expansion: Penetrating emerging markets, particularly in developing countries where healthcare services are expanding, offers opportunities for increased sales and market share.

Predictions and Growth Strategies for Manufacturers

Manufacturers of Procain must adopt forward-thinking strategies to capitalize on emerging trends and ensure sustainable growth.

- Investment in R&D: Allocating resources to research and development can lead to the discovery of innovative production methods or new pharmaceutical formulations, setting a company apart from its competitors.

- Strategic Alliances: Forming partnerships with other pharmaceutical companies or academic institutions can facilitate knowledge exchange, open new research avenues, and potentially reduce costs through shared resources.

- Market Analysis and Forecasting: Keeping abreast of market trends and forecasts enables manufacturers to anticipate changes in demand and adjust their production and marketing strategies accordingly. For example, monitoring the global demand for local anesthetics can help in aligning production volumes with market needs, optimizing inventory levels, and pricing strategies.

The future of Procain manufacturing hinges on embracing new technologies, exploring untapped markets, and innovating continuously. These strategies not only foster growth and profitability but also ensure the manufacturer remains relevant and competitive in a changing pharmaceutical landscape.

Conclusion

The exploration into the world of Procain and its manufacturing processes reveals both the complexities and opportunities within this segment of the pharmaceutical industry. This concluding section aims to encapsulate the key insights drawn from the various aspects of Procain production and project a future outlook for its manufacturers.

Summarizing Key Insights

The journey through the landscape of Procain manufacturing unveils several vital points:

- Manufacturing Efficiency and Costs: Optimizing the manufacturing process for efficiency and cost-effectiveness remains crucial. Innovative production technologies not only streamline operations but also significantly reduce expenses. For example, adopting automated synthesis can save substantial labor costs and decrease the error margin, contributing to both quality and financial benefits.

- Quality and Compliance: Adhering to stringent quality control standards and regulatory compliance, like those set by the FDA and EMA, is non-negotiable for manufacturers. Investing in quality control and compliance mechanisms, although initially costly, safeguards against potential legal and reputational risks, ensuring long-term viability.

- Market Adaptability: Understanding and adapting to market needs — whether it’s expanding into new regions or exploring alternative applications of Procain in medicine — is essential for sustained growth. By continually analyzing market trends and customer feedback, manufacturers can pivot or adjust their strategies effectively.

Future Outlook for Procain Manufacturers

Looking ahead, Procain manufacturers face a dynamic and challenging landscape, shaped by both external market forces and internal industry innovations:

- Embracing Technological Advancements: Continuous investment in emerging technologies, especially those that promote sustainable and green manufacturing processes, will become increasingly important. Such advancements not only improve efficiency and reduce environmental impact but also resonate with the growing global emphasis on sustainable practices.

- Global Market Shifts: The manufacturers must remain vigilant and responsive to global healthcare trends, including shifts in demographic patterns, healthcare policies, and insurance coverages, which can all influence the demand for pharmaceutical products like Procain.

- Strategic Partnerships and Collaborations: Building strategic alliances with other players in the pharmaceutical industry, including biotech startups, research institutions, and even competitors, can lead to new opportunities for innovation and expansion.

In summary, the future for Procain manufacturers is brimming with possibilities and challenges. Success hinges on their ability to innovate, adapt, and maintain high standards of quality and efficiency. By keeping a finger on the pulse of technological advancements, regulatory changes, and market needs, manufacturers of Procain can navigate these waters to achieve growth and establish a strong presence in the competitive pharmaceutical landscape.