No, lube and grease are not the same; they have different consistencies, applications, and chemical compositions.

The Chemistry of Lube and Grease

Base Oils

Within the lubrication industry, base oils serve as the foundation in the formulation of both lubes and greases.

Types of Base Oils

When we delve deeper into base oils, we find them classified into groups ranging from Group I to Group V based on their sulfur content, viscosity index, and the manufacturing process involved. Here we explore these groups and their characteristics.

Sources and Extraction

Detailing the sources of base oils, we touch upon the petroleum-based sources, and the advancements in synthetic methods which include the processes like hydrocracking. An overview of the extraction methods involved would give a clear picture of how base oils are produced.

Additives and Thickeners

Additives and thickeners hold a pivotal role in determining the performance characteristics of lubes and greases. They enhance the basic properties and impart new ones to the lubricants. Here we delineate various additives and thickeners used in the industry.

Role and Functionality

Understanding the role and functionality of additives is essential. From anti-oxidants to corrosion inhibitors, each additive has a role to play. We explore how they work and their impact on the performance of lubes and greases.

New Developments

New developments in the field of additives and thickeners have brought to the forefront environmentally friendly options and high-performance additives. We delve into these developments and the future trajectory in this area.

Viscosity and Consistency

Viscosity and consistency are critical parameters in the performance of lubes and greases. They affect how a lubricant behaves under different conditions and hence dictate their applications.

Measuring Techniques

Understanding the different techniques involved in measuring viscosity such as rotational viscometry, and how consistency is measured, forms an essential part of this section.

Importance in Application Selection

Here, we detail how the viscosity and consistency of a lubricant can influence the choice of application, underscoring the necessity to choose the right lubricant for different machinery and environments, drawing from a range of real-world examples.

Types of Lubes

Understanding the different types of lubricants can aid in selecting the most suitable one for a specific application. It is critical to appreciate the unique characteristics and functionalities that liquid, semi-solid, and spray lubricants offer.

Liquid Lubricants

Liquid lubricants are often the go-to choice in many industrial and mechanical processes due to their flowable nature and excellent lubricating properties. We delve deep into the various types and their respective features in this section.

Applications

Liquid lubricants find themselves in an array of applications, including in automotive engines and industrial machinery. We will explore the specific scenarios where they provide optimal performance.

Benefits and Drawbacks

In this segment, we outline the advantages and the downsides of using liquid lubricants, discussing aspects such as their cooling ability and potential for leakage.

Semi-Solid Lubricants

Semi-solid lubricants stand halfway between liquid and solid lubricants, offering a different set of characteristics and benefits. Let’s take a close look at what makes semi-solid lubricants a preferred choice in certain scenarios.

Greases

Here we focus on grease, a common type of semi-solid lubricant, discussing its formulation, and how it operates in reducing friction and wear in machinery parts, linking to its Wikipedia page for a deep dive into its chemistry and applications.

Applications and Uses

This part zeroes in on the various applications and the contexts in which semi-solid lubricants excel, providing examples from industries such as mining and manufacturing.

Spray Lubricants

Spray lubricants come packed in aerosol cans and offer easy application. In this section, we understand the composition and the applications where spray lubricants emerge as the most fitting option.

Types and Composition

In this sub-section, we take a closer look at the different types of spray lubricants available in the market, the ingredients that make them up, and how to choose the right one based on the composition.

Practical Uses

Detailing the practical uses of spray lubricants, we provide insights into the convenience and efficiency they bring to lubrication tasks, with examples ranging from household chores to industrial maintenance.

Types of Greases

A comprehensive understanding of the different types of greases is essential to optimize their use in various applications. In this section, we delve into the specifics of mineral, synthetic, and silicone greases.

Mineral Greases

Mineral greases are derived from petroleum and have a wide range of applications due to their natural resistance to heat and anti-wear properties.

Characteristics

In this part, we’ll delve into the defining characteristics of mineral greases, touching upon aspects such as their thermal stability and oxidative resistance.

Applications

Here we survey the extensive applications of mineral greases, with a focus on sectors such as automotive and manufacturing, linking to the Wikipedia page for a deeper insight.

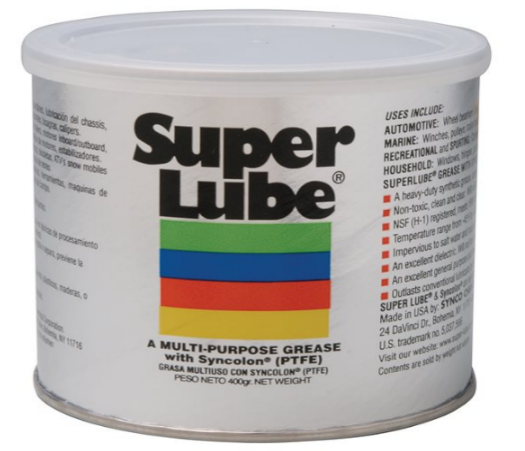

Synthetic Greases

Synthetic greases, which are formulated through chemical synthesis, offer a high performance in extreme temperature conditions. Let’s take a look at why they are often preferred over mineral greases in certain applications.

Varieties and Formulations

In this segment, we examine the various types of synthetic greases available in the market and their formulations, which lend them a higher stability and a broader temperature operational range.

Usage Scenarios

Here we go through different scenarios where synthetic greases find utility, spotlighting their use in high-speed bearings and aviation, supported with real-life examples to provide a concrete understanding.

Silicone Greases

Silicone greases are known for their excellent water resistance and wide temperature operating range, making them ideal for specific applications. Let’s explore the various aspects that define silicone greases.

Composition and Properties

Delving deep into the composition and properties of silicone greases, we will link to its Wikipedia page for readers to get detailed knowledge on its chemical makeup and benefits.

Industrial and Household Uses

In this segment, we look into both industrial and common household uses of silicone greases, emphasizing their role in electrical insulation and as sealant agents, offering a comprehensive view of their utility.

Applications and Uses

Greases and lubes play a pivotal role in a multitude of settings, ranging from vast industrial complexes to daily household chores. In this segment, we delve deep into the diverse applications and the pivotal role they play in the seamless functioning of machinery and appliances.

Lube in Industrial Applications

Lubes are indispensable in the industrial sector, offering reduced friction and wear, and thereby enhancing the lifespan of machinery. Let’s investigate the various applications where lubes hold a significant role.

Automotive Industry

Within the automotive sector, lubes find extensive use in reducing friction in engine components, thereby enhancing performance. Dive deeper into this topic with detailed insights from its Wikipedia page.

Manufacturing Units

Manufacturing units deploy lubes in a variety of machines to ensure their smooth operation, minimizing downtime and maximizing productivity. We will explore the role lubes play in different manufacturing settings, including their function in reducing noise levels.

Grease in Industrial Applications

Grease, with its semi-solid nature, finds favor in a variety of industrial applications. In this section, we explore the different scenarios where grease turns out to be the preferred choice.

Heavy Machinery

In this subsection, we shed light on the application of grease in heavy machinery used in industries such as mining and construction, detailing its role in maintaining the durability of essential equipment.

Marine Applications

Diving into marine applications, we look at how grease ensures the smooth operation of ship components, protecting them from the harsh marine environment, including high salt concentrations that can lead to corrosion.

Common Household Uses

Beyond the industrial sector, lubes and greases find extensive usage in households, helping in the maintenance of various appliances and tools. Let’s take a closer look at some common household uses.

Maintenance of Appliances

Here, we discuss how lubes and greases aid in the maintenance of household appliances, reducing wear and tear and ensuring a longer lifespan for devices such as washing machines and air conditioners.

DIY and Home Improvement

In this section, we enumerate the role of lubes and greases in DIY and home improvement projects, offering tips on how to choose the right product for different tasks, backed by insights from experts in the field.

Choosing Between Lube and Grease

Selecting the ideal lubricant between lube and grease can be pivotal in ensuring the optimal functioning and longevity of machinery. It involves considering various factors including environmental conditions, load, speed, and temperature requirements. In this section, we explore these critical determining factors in detail.

Considering the Environment

The external environment can greatly influence the choice between lube and grease. Here, we take a detailed look at how different environmental conditions can affect this choice.

Dusty and Contaminated Areas

In environments prone to dust and contamination, selecting the right kind of lubricant becomes critical. Here, we discuss how grease can sometimes offer a sealing effect, protecting machinery components from external contaminants.

Water Exposure

Understanding the role water plays in the choice of lubricants is essential. We explore how different lubricants respond to water exposure, with links to the detailed Wikipedia page for a broader perspective on the topic.

Assessing the Load and Speed

The performance demands of a machinery, in terms of load and speed, can be a decisive factor in the selection between lube and grease. Let’s dig deeper into this aspect.

High-Speed Operations

In this section, we assess the suitability of lubes for high-speed operations, where the rapid movement of components necessitates a lubricant with specific characteristics to prevent overheating and reduce friction effectively.

Heavy Load Conditions

Here, we focus on the applications involving heavy loads and how grease, with its thicker consistency, can be a more suitable choice, providing insights into the role of viscosity in managing heavy load conditions.

Temperature Requirements

Temperature can significantly influence the behavior of a lubricant. In this segment, we delve into how temperature requirements should guide the choice between lube and grease.

Low-Temperature Environments

We look into the specifics of choosing a lubricant for low-temperature environments, discussing the role of pour point in the selection process and how different types of lubes and greases perform under cold conditions.

High-Temperature Operations

In this subsection, we discuss the ideal choices for high-temperature operations, emphasizing the need for lubricants that can withstand high temperatures without breaking down, with insights gleaned from expert resources and Wikipedia.

Case Studies

In this segment, we will be examining real-world scenarios to shed light on the successful implementation of lubes and greases in machinery. Through various case studies, we offer a tangible insight into the decisive role these substances play in the functioning of different machinery, and how they can significantly affect outcomes in different setups.

Successful Usage of Lube in Machinery

Through a collection of real-world scenarios, we highlight the successful implementation of lubes in different machinery, showcasing the value they bring in ensuring the smooth operation and longevity of equipment.

Automotive Industry

In this section, we bring forward case studies from the automotive industry, highlighting instances where the correct usage of lube has led to enhanced performance and reduced maintenance costs in vehicles. We will supplement this with relevant statistics and insights from industry reports.

Manufacturing Sector

Here, we offer cases from the manufacturing sector, spotlighting the crucial role lube plays in reducing friction between machinery parts, consequently minimizing wear and tear, and extending the lifespan of the machines.

Successful Usage of Grease in Machinery

In this part, we delve into real-world cases that underscore the successful application of grease in machinery, highlighting how it has been pivotal in enhancing efficiency and operational lifespan.

Construction Industry

We share insights from the construction industry, showcasing real-world scenarios where the correct application of grease has ensured the optimal functioning of heavy machinery, referring to industry-specific examples to underline its significance.

Food Production

In the food production industry, we explore the vital role that grease plays in machinery, bringing forward cases that highlight its importance in maintaining hygiene and efficiency in production lines, with reference to authoritative resources for in-depth understanding.

Comparative Analysis

In this section, we carry out a comparative analysis of the usage of lube and grease in different machinery, drawing from real-world examples to offer a balanced view of their respective strengths and applications.

Efficiency and Longevity

Here, we undertake a comparative study of how both lube and grease can influence the efficiency and longevity of machinery, analyzing different parameters such as friction reduction, heat dissipation, and protection against contaminants.

Cost-Benefit Analysis

In this subsection, we perform a cost-benefit analysis comparing the economic aspects of using lube and grease, taking into account factors like maintenance costs, lifespan, and efficiency to offer readers a comprehensive overview to aid in informed decision-making.

Health, Safety, and Environmental Concerns

In the journey to understanding the integral role of lubes and greases, it is imperative to delve into the health, safety, and environmental concerns that encompass their usage. This section elucidates the various facets of safety and regulatory norms associated with handling and using these substances.

Safe Handling and Storage

Ensuring safety while handling and storing lubes and greases is paramount. This subsection sheds light on the strategies and best practices to adopt for a safe environment.

Proper Labeling

We emphasize the necessity of proper labeling of containers to prevent mishandling and to provide clear instructions for safe usage. The labels should adhere to the guidelines set by regulatory bodies, pointing users to safety data sheets for detailed information, including links to relevant resources.

Ventilated Storage

In this part, we discuss the importance of storing lubes and greases in well-ventilated areas to prevent the accumulation of harmful fumes which can pose health risks, guiding users on how to set up safe storage spaces.

Disposal Considerations

Disposal of lubes and greases requires meticulous attention to prevent adverse effects on the environment. Here, we delve into the measures to be adopted for responsible disposal.

Recycling Opportunities

We explore the potential avenues for recycling used lubes and greases, emphasizing the importance of seeking out recycling facilities and promoting sustainable practices to safeguard the environment.

Hazardous Waste Management

In this section, we detail the protocols for handling hazardous waste, guiding users to adhere to the regulations stipulated by environmental agencies, and ensuring the safe disposal of these materials to prevent soil and water contamination, with reference to Wikipedia for a detailed understanding.

Regulatory Compliance

Adhering to regulatory compliance is a non-negotiable aspect in the handling of lubes and greases. We outline the key compliance factors to be aware of, in this segment.

Occupational Safety

We underscore the significance of abiding by the safety norms laid out by occupational safety agencies, providing insights into the safety gear and training that are essential for personnel handling these substances.

Environmental Regulations

Delving into the environmental regulations, we detail the guidelines established by environmental protection agencies globally, advising users to stay abreast of the latest regulations to ensure compliance and foster a culture of responsibility and care towards the environment.