Overview of CNC and Laser Technologies

In the dynamic field of manufacturing and fabrication, CNC (Computer Numerical Control) and laser cutting systems stand as beacons of innovation. These technologies revolutionize precision and efficiency, carving out indispensable roles in diverse industrial applications.

Definition and Working Principles of CNC

CNC technology, a linchpin in contemporary manufacturing, brings digital designs to life with remarkable accuracy. A CNC machine meticulously follows a set of digital instructions to shape materials. It employs various tools like drills and mills, all under precise computer control, to mold materials into desired configurations. Versatile in nature, CNC machines work with an array of materials, including metals, plastics, and wood. The standout feature of CNC is its exceptional ability to craft complex shapes with consistent precision. Generally, these machines attain tolerances as tight as 0.005 inches (0.127 mm), though specific capabilities may vary with different machines and materials.

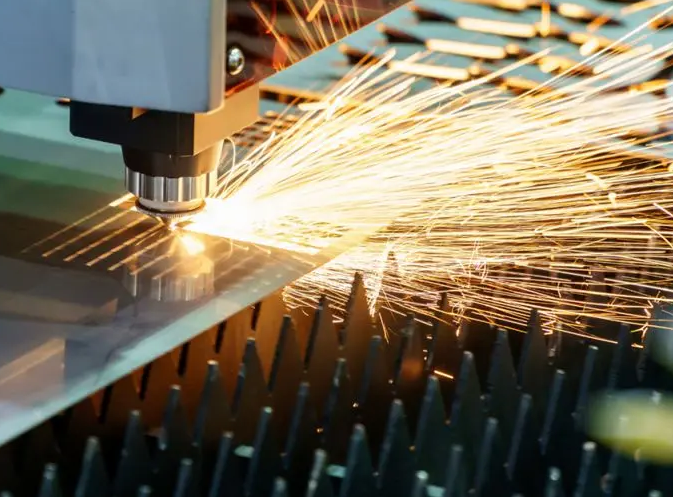

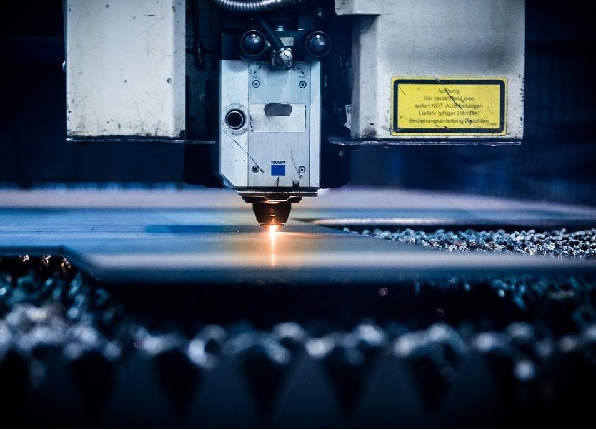

Definition and Working Principles of Laser Cutting

Laser cutting, a true technological gem, utilizes a potent laser beam to slice through or etch materials. This process involves directing the laser through mirrors to a focused point on the material. The intense heat from the laser beam then melts, burns, or vaporizes the material, resulting in a precise and clean cut. Ideal for materials like metals, plastics, glass, and wood, laser cutters are known for their ability to achieve intricate details and complex patterns. The efficiency of a laser cutter, influenced by laser power and material thickness, varies accordingly. For example, a 1500-watt laser cutter can efficiently cut through 0.6-inch (15 mm) thick mild steel at about 40 inches per minute (1016 mm/min).

Both CNC and laser cutting technologies are vital in modern manufacturing, offering unparalleled precision, speed, and adaptability. Their influence stretches across various industries, from automotive to aerospace, significantly advancing manufacturing processes. Despite sharing similarities in precision and automation, they diverge in their principles, cost implications, and application suitability, each marked by its unique strengths and capabilities.

Cost Analysis of CNC Machines

Delving into the financial aspects of CNC machines reveals a complex landscape of investments and ongoing expenses. Understanding these costs is crucial for businesses planning to integrate CNC technology into their operations.

Initial Investment and Setup Costs

The initial investment for a CNC machine can be substantial, varying widely based on the machine’s size, capabilities, and sophistication. Entry-level CNC machines may start around $5,000, while more advanced models, designed for industrial use, can easily surpass $100,000. This initial cost not only includes the machine itself but also encompasses software licenses, tooling, and any necessary training for operators. Additionally, setting up a CNC machine requires a dedicated space with proper power supply and safety measures, potentially adding to the initial budget. Factors like power requirements, which can range from a standard 110V outlet for smaller machines to 220V or higher for industrial models, also influence setup costs.

Ongoing Maintenance and Operational Costs

Once operational, CNC machines incur ongoing expenses, primarily for maintenance, tooling, and energy consumption. Regular maintenance ensures the machine operates at peak efficiency and extends its lifespan, which can be over 10 years with proper care. Tooling costs, including replacement of drill bits and end mills, depend on usage frequency and the materials being machined. For instance, machining hard materials like stainless steel requires more frequent tool replacements compared to softer materials like aluminum. Energy consumption, another significant factor, hinges on the machine’s power rating and operational hours. A typical CNC machine may consume about 5 kW of power per hour, translating to energy costs that must be factored into the overall budget.

In summary, while CNC machines offer unparalleled precision and efficiency, these benefits come with considerable financial commitments, both upfront and over the long term. Understanding these costs is pivotal for businesses to make informed decisions and optimize their investment in CNC technology.

Cost Analysis of Laser Cutting Systems

Exploring the financial landscape of laser cutting systems unveils a detailed picture of initial and ongoing expenditures. These costs play a pivotal role in decision-making for businesses considering the adoption of laser technology.

Equipment Purchase and Installation Expenses

The purchase price of laser cutting systems varies significantly, mainly depending on their power, size, and technological sophistication. Basic models start around $10,000, but high-end industrial machines can reach or exceed $500,000. This price includes the laser cutter itself and often basic software. However, additional costs arise from specialized software upgrades, optional accessories, and installation services. The power requirements for these machines also contribute to installation expenses. For example, a machine with a 2 kW laser requires a stable power supply and might need electrical upgrades in certain facilities. Furthermore, ensuring a safe operation environment, with adequate ventilation and safety equipment, adds to the initial financial outlay.

Long-term Running and Repair Costs

After installation, laser cutting systems incur ongoing costs for operation and maintenance. These expenses include utilities, primarily electricity, and the cost of consumables like lenses and nozzles. The power consumption of a laser cutter depends on its wattage and operational intensity. For instance, a 3 kW laser cutter, running at full capacity, consumes approximately 3 kWh of electricity. Regular maintenance, crucial for optimal performance, involves periodic servicing and potential part replacements, which vary based on usage frequency and material types being cut. Additionally, repairs for breakdowns, though infrequent with proper maintenance, can be costly, especially if they involve replacing major components like the laser source. These long-term expenses are essential factors in the total cost of ownership of a laser cutting system, impacting its overall value and return on investment for a business.

Comparison of Precision and Quality

Comparing CNC and laser cutting reveals insights into their precision and quality, critical factors for industries requiring high accuracy.

Precision Levels in CNC versus Laser Cutting

CNC machines excel in precision, often reaching tolerances as tight as 0.005 inches (0.127 mm). Their ability to handle complex 3D geometries makes them ideal for intricate designs. On the other hand, laser cutting stands out for its exceptional accuracy in 2D cutting, typically achieving tolerances within 0.004 inches (0.1 mm). The precision of laser cutting shines in producing fine details and small cutouts, which might be challenging for some CNC machines.

Quality of Finished Products: CNC vs. Laser

In terms of finished product quality, CNC machines provide excellent surface finishes, especially in subtractive processes involving metals and plastics. They are adept at creating parts with smooth surfaces and sharp edges. Laser cutters, meanwhile, offer a high-quality finish in cutting thin materials, with minimal warping and a clean edge that usually requires no further processing. However, in thicker materials, laser cutting might lead to slight thermal distortion, an aspect where CNC machining generally maintains consistency.

Both technologies have their unique strengths and ideal applications. CNC is often the go-to choice for complex 3D shapes and high-quality surface finishes, while laser cutting is preferred for its precision in thin materials and speed in 2D cutting tasks. The choice between CNC and laser cutting ultimately depends on the specific requirements of the project, including material type, thickness, and desired accuracy.

Application Areas and Material Suitability

Identifying the right technology for specific applications and materials is crucial in maximizing efficiency and quality in manufacturing.

Best Use Cases for CNC Machining

CNC machining excels in applications requiring high precision and complex 3D shapes. Ideal for both metal and plastic parts, it’s widely used in the automotive, aerospace, and medical industries. For instance, CNC machines are indispensable in producing engine components, aerospace parts, and intricate medical devices. They handle materials like aluminum, steel, titanium, and various plastics, maintaining high precision even with hard materials. CNC is also the preferred choice for custom one-off projects and prototypes due to its versatility and adaptability.

Ideal Applications for Laser Cutting Technology

Laser cutting technology shines in applications demanding high speed and precision, particularly with thin materials. It’s optimal for cutting sheet metal, making it a staple in the manufacturing of electronics, signage, and jewelry. Laser cutters work exceptionally well with materials like mild steel, stainless steel, aluminum, and various plastics. They are also ideal for detailed engraving tasks on wood and acrylic. The technology’s capability to deliver fine, intricate cuts with minimal material waste makes it a top choice for detailed 2D designs.

Both CNC machining and laser cutting have distinct strengths, making them suitable for a range of applications. The choice between them hinges on specific project requirements, including the type of material, desired precision, and complexity of the design.

Long-Term Financial Implications

Evaluating the long-term financial implications is key to making informed decisions when investing in CNC or laser cutting systems.

Depreciation and Resale Value: CNC vs. Laser

CNC machines typically exhibit slower depreciation rates due to their robust build and long lifespan, often over 10 years. A well-maintained CNC machine can retain a significant portion of its value, with potential resale values ranging from 50% to 70% of the original price, depending on the brand, condition, and market demand. In contrast, laser cutting systems, especially those with advanced technology, may depreciate faster due to continuous innovations in laser technology. Their resale value, while still significant, might range from 40% to 60% of the initial cost. The rate of depreciation for both types of equipment also depends on how well they are maintained and updated with the latest software and hardware enhancements.

Return on Investment and Profitability Comparison

The return on investment (ROI) for CNC machines and laser cutters depends on factors like initial cost, operational efficiency, maintenance costs, and the revenue generated from their use. CNC machines generally offer a higher ROI in custom and prototype manufacturing, where their versatility allows for a wide range of products. Laser cutters, with their speed and precision, are more profitable in high-volume production settings, particularly when working with thin materials. The profitability of these machines is closely tied to their utilization rates; higher usage typically leads to a quicker ROI. For instance, a business using a laser cutter for mass production of parts can expect a faster ROI compared to one using it sporadically for small, custom jobs.

In conclusion, both CNC and laser cutting systems come with distinct financial implications over the long term. The choice between them should align with the specific production needs, expected usage, and the business’s financial strategy.