Most cars have two axles, supporting four wheels in total.

Introduction

Vehicles, whether they’re compact cars or massive trucks, play a pivotal role in our daily lives. At the heart of these machines, ensuring they roll smoothly and safely, are the axles.

Brief overview of the importance of axles in vehicles

Axles are integral components in any vehicle. They’re responsible for transferring power from the engine to the wheels, enabling the car to move. Moreover, axles bear the weight of both the vehicle and its passengers, ensuring stability while on the move. A car without an axle is like a human without a spine – it simply can’t function properly.

When it comes to the efficiency of vehicles, axles play a crucial role. For example, the power delivered from an engine to the wheels can be affected by the axle’s design and material. A well-designed axle can effectively transmit 200 horsepower with minimal energy loss, while a subpar axle may lose a significant amount, reducing the car’s overall efficiency.

Furthermore, the cost of producing axles can significantly impact the overall price of a vehicle. A high-quality axle made of premium materials might cost upwards of $1,000, while a cheaper variant might be priced around $400. This difference in cost can be reflected in the vehicle’s overall price.

Definition of an axle

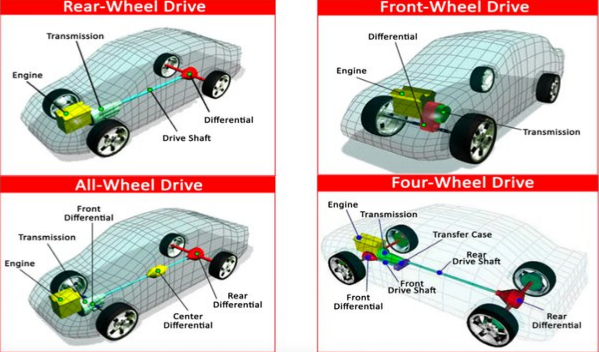

An axle is a central shaft for a rotating wheel or gear. In vehicles, it can be either driving the wheels, primarily in rear-wheel drive vehicles, or be driven by them, as in most front-wheel drive cars. The axle serves as a fundamental component in the car’s suspension system, linking two opposite wheels together.

When discussing the dimensions or specifications of axles, various parameters come into play. For example, the diameter of a standard car axle might range from 1 to 2.5 inches, depending on the vehicle’s size and purpose. The material quality, often high-grade steel or alloy, also determines the axle’s lifespan. Typically, a well-maintained axle can last upwards of 200,000 miles, but this figure can vary based on usage and maintenance.

History of the Automobile Axle

The automobile axle has evolved significantly since the dawn of motorized transportation. As cars transitioned from mere novelties to essential transportation tools, so did the technology and design of the axle, enhancing both performance and safety.

Evolution of the axle from early vehicles to modern cars

The earliest vehicles, such as the horse-drawn carriages, utilized simple wooden axles. However, as the horsepower of early automobiles increased, the demand for stronger and more efficient axles grew. By the early 20th century, steel had become the preferred material for axles, providing the required strength to support heavier vehicles and higher speeds.

In the 1920s, as cars became more mainstream, the split-axle design emerged. This design allowed each wheel to move independently, offering better handling and a smoother ride. The innovation was pivotal in the automobile industry, as it greatly improved driving comfort and safety.

Fast forward to the 1980s and 1990s, the introduction of front-wheel drive (FWD) in many passenger cars led to the widespread use of the transaxle. This combined the transmission and axle into one unit, optimizing space and efficiency.

Today’s modern cars, especially those with electric drivetrains, often use axles made of advanced alloys and composite materials. These materials, while expensive with prices sometimes exceeding $2,000 for high-end models, offer a combination of lightweight properties and durability. With the electric car market pushing for longer ranges, the weight-saving benefits these materials provide cannot be overstated.

Milestones in axle design and technology

- 1900s: Introduction of steel as the primary material for axles, replacing wood. This shift marked a significant increase in both the durability and weight-bearing capacity of axles.

- 1920s: The split-axle design becomes prevalent. It provides superior handling and a more comfortable ride, marking a massive improvement over the rigid axles of previous decades.

- 1970s-1980s: The rise of FWD cars led to the adaptation of the transaxle, a major shift in design that optimized space and efficiency. The typical lifespan of these axles ranged between 150,000 to 200,000 miles, given proper maintenance.

- 2000s and beyond: With the push towards electric vehicles, there’s a significant emphasis on reducing weight to increase efficiency. Advanced alloys and composite materials become the go-to choice for many manufacturers. Furthermore, the integration of sensors and electronic components into axles becomes more common, paving the way for smarter and more responsive vehicle dynamics.

Types of Axles

As the automobile industry has evolved, so too have the designs and functionalities of axles. Various types of axles serve different purposes, cater to different driving conditions, and offer unique advantages.

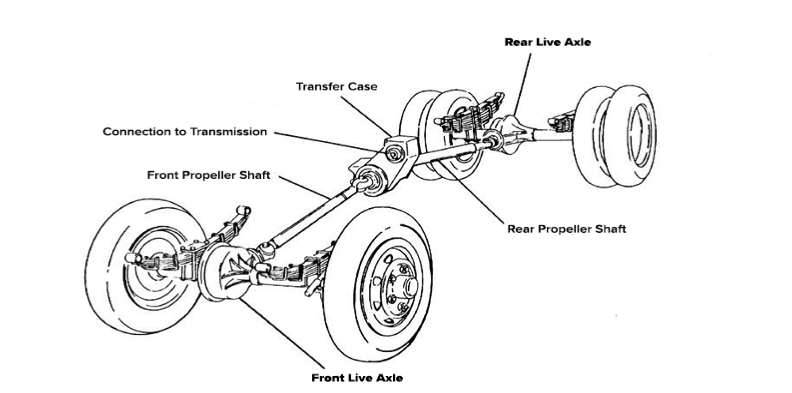

Live axles vs. Dead axles

- Live Axles: A live axle, also known as a driving axle, is directly connected to the engine and transmits power to the wheels. Due to this, when the engine runs, the axle rotates. Live axles are primarily found in rear-wheel-drive vehicles. They are robust, often constructed from high-strength steel, and can effectively transmit power up to 300 horsepower in typical passenger cars. However, they can be heavier, which might slightly impact the vehicle’s overall efficiency.Advantages:

- Efficient power transmission.

- Robust and can handle high torque.

Disadvantages:

- Heavier, potentially affecting fuel efficiency.

- Can be more expensive, with prices ranging from $800 to $1,500 depending on the make and model.

- Dead Axles: Unlike live axles, dead axles do not transmit power. Instead, they serve primarily to support the weight of the vehicle. Commonly found in front-wheel-drive cars, these axles rotate freely without any connection to the drivetrain. They are generally lighter and less costly, with prices typically ranging from $400 to $900.Advantages:

- Lightweight, potentially improving fuel efficiency.

- Less complex and therefore more affordable.

Disadvantages:

- Do not contribute to power transmission.

Front axles vs. Rear axles

- Front Axles: Found in the front of vehicles, these axles bear the weight of the front part of the vehicle and also assist in steering. In front-wheel-drive vehicles, the front axles are live axles. Their design considerations include ensuring smooth steering and managing the stress from braking, especially given the significant weight they bear.

- Rear Axles: Positioned at the rear, these axles carry the weight of the rear part of the vehicle. In rear-wheel-drive vehicles, the rear axles are live axles. Their primary role is to deliver power to the rear wheels and support the vehicle’s weight.

Tandem Axles

Tandem axles refer to a set-up where two axles – and thus four wheels – are placed in sequence in a single vehicle, often seen in trucks and trailers. This design distributes the weight of the vehicle more evenly, allowing for the transportation of heavier loads. The use of tandem axles can significantly extend tire life and improve stability, especially at high speeds.

Advantages:

- Enhanced weight distribution.

- Improved stability and safety for heavy loads.

Disadvantages:

- Increased maintenance costs due to more moving parts.

Function and Purpose of Axles

Axles, while often overlooked in favor of more glamorous car components like engines or interiors, serve as the backbone of a vehicle’s mobility and stability. Their primary functions encompass weight distribution, and they play a crucial role in the vehicle’s suspension and driving dynamics.

How axles distribute weight

Axles are ingeniously designed to handle and distribute the weight of a vehicle, ensuring it remains stable during motion. When a car accelerates, brakes, or takes a turn, weight shifts occur. These shifts can affect the car’s balance and overall performance. Axles help manage these shifts by distributing the weight evenly across the vehicle’s width.

For instance, consider a standard sedan weighing around 3,000 pounds. The axle ensures that this weight isn’t concentrated on a single point, which would compromise the vehicle’s stability. Instead, it spreads this weight across its length, ensuring each wheel bears an approximate quarter of the total weight, or 750 pounds. This equal distribution is vital for maintaining the car’s balance, especially during dynamic maneuvers.

The weight-bearing ability of an axle is often denoted by its specifications. Heavy-duty trucks, for example, might employ axles capable of supporting weights upwards of 20,000 pounds, while a compact car’s axle might support around 4,000 pounds.

Role in vehicle suspension and driving dynamics

The axle doesn’t work in isolation. It’s an integral part of the vehicle’s suspension system, affecting how a car feels and responds during driving. The axle’s interaction with the suspension system determines factors like ride comfort, handling, and the ability to absorb road shocks.

- Ride Comfort: A vehicle’s axle, in conjunction with its suspension, determines how smoothly it rides. Bumps and potholes can be jarring, but the axle helps absorb and distribute these forces, reducing the direct impact felt by passengers.

- Handling: Axles play a role in how a vehicle responds to steering input. For instance, a sports car, aiming for agility and quick response, might employ a specific axle design to achieve tighter handling, allowing it to navigate sharp turns at higher speeds.

- Absorbing Shocks: Roads aren’t always smooth. When a car encounters irregularities, it’s the axle, along with the suspension, that absorbs these shocks. This not only ensures comfort but also prevents potential damage to the vehicle’s components.

- Efficiency: An optimally functioning axle can also contribute to a car’s overall efficiency. By ensuring proper weight distribution and minimizing unnecessary friction, axles can indirectly help in improving a car’s fuel efficiency.

In essence, while the engine might be the heart of a car, the axle, in many ways, is its spine – providing support, ensuring balance, and playing a pivotal role in how a car feels and performs on the road.

Common Axle Configurations in Cars

The axle configuration in a car greatly influences its performance, stability, and utility. From everyday passenger cars to specialized vehicles, the axle setup is tailored to meet specific needs and functions.

Two-axle vehicles

The majority of passenger cars, trucks, and SUVs on the road today are two-axle vehicles. This means they have a front and a rear axle, with each axle supporting two wheels. This configuration offers a balanced weight distribution, ensuring stability and safety for the passengers.

For example, a typical sedan might weigh around 3,200 pounds. With a two-axle setup, this weight gets evenly distributed, ensuring optimal performance and efficiency. The cost of maintaining a standard two-axle system is relatively low, averaging around $500 to $1,000 annually, depending on wear and tear and specific maintenance needs.

Advantages:

- Balanced weight distribution.

- Suited for a wide range of terrains and driving conditions.

Disadvantages:

- Limited weight-bearing capacity compared to multi-axle vehicles.

Vehicles with more than two axles

Vehicles with more than two axles are typically designed for specialized purposes. They might be used to carry heavy loads, traverse challenging terrains, or for specific industrial applications. An example includes six-wheeler trucks or certain luxury limousines.

A three-axle truck can bear loads upwards of 26,000 pounds, making it ideal for transporting heavy goods. However, the cost associated with maintaining such vehicles is higher, due to the added complexity of the axle system.

Advantages:

- Increased weight-bearing capacity.

- Enhanced stability for heavy loads.

Disadvantages:

- Higher maintenance and operational costs.

- Reduced fuel efficiency due to added weight.

Special vehicles and their unique axle configurations

Special vehicles, such as monster trucks, certain military vehicles, or specialized construction machinery, often have unique axle configurations tailored to their specific needs. For instance, a monster truck, designed for off-road entertainment shows, might employ multiple axles with independent suspension systems to achieve high jumps and withstand rough landings. Such configurations could cost upwards of $100,000, given the specialized materials and engineering involved.

Advantages:

- Tailored performance for specific tasks.

- Enhanced durability in challenging conditions.

Disadvantages:

- High manufacturing and maintenance costs.

- Limited applicability outside of their specialized domain.

Axle Maintenance and Issues

Axles are integral components of a vehicle’s structure and functionality. Like all parts of a car, axles are subject to wear and tear over time. Proper maintenance and understanding potential issues can ensure their longevity and the safety of the vehicle.

Common signs of axle wear and damage

- Loud Noises: One of the earliest signs of axle issues is strange noises. If you hear clunking or clicking sounds, especially during turns, it could indicate a problem with the CV joints, which are part of the axle assembly.

- Vibrations: Feeling unusual vibrations while driving, particularly in the steering wheel, can be a sign of a damaged or misaligned axle.

- Difficulty Steering: If steering becomes unusually hard, especially during turns, it might be a result of axle damage or wear.

- Grease Leaks: CV joints are lubricated with grease. If you notice grease on the inside edge of your tires, it might be from a torn boot, exposing the CV joint to dirt and debris.

- Uneven Tire Wear: A malfunctioning axle can lead to uneven tire wear, which not only affects the efficiency of the vehicle but also poses safety risks.

Maintenance tips to prolong axle life

- Regular Inspections: Make it a habit to inspect your axles every time you get an oil change or at least twice a year. Look for signs of wear, cracks, or any potential damage.

- Lubricate CV Joints: Ensuring that CV joints are well-lubricated can prolong their lifespan. If a boot is torn, replace it immediately and replenish the lost grease.

- Avoid Overloading: Every vehicle has a weight limit. Consistently overloading your vehicle can put undue stress on the axles, leading to premature wear.

- Drive Carefully: Avoiding potholes and taking care not to hit curbs can reduce the chances of sudden and severe axle damage.

- Replace When Needed: If there’s substantial damage or wear to any part of the axle, it’s essential to replace it. While the cost can range from $500 to $1,500 depending on the vehicle and type of axle, it’s a necessary investment for safety.

Potential risks of neglected axles

- Reduced Vehicle Control: A damaged axle can affect the car’s alignment and steering, reducing the driver’s control over the vehicle.

- Safety Hazard: A severely damaged axle can break, leading to catastrophic consequences, especially if the vehicle is in motion.

- Increased Wear on Other Parts: An ignored axle issue can lead to increased wear and tear on other vehicle components, such as the tires and suspension system.

- Higher Long-Term Costs: Neglecting minor axle issues can lead to more severe problems down the line, resulting in higher repair costs.

Future of Car Axles

The automotive industry is in the midst of a transformative phase, driven by electrification, digitization, and the move towards autonomous driving. As these shifts occur, the design and requirements of car axles are also evolving to meet new challenges and leverage new opportunities.

Innovations in axle design and materials

Modern vehicles are demanding lighter, stronger, and more efficient components. The axle, being a core component, is no exception.

- Advanced Materials: Traditional steel axles are gradually being replaced or supplemented by materials like carbon fiber and advanced alloys. These materials offer a unique combination of strength and lightness. For instance, a carbon-fiber axle might weigh 40% less than its steel counterpart but offer similar or even superior strength. However, the cost of these materials can be high, with carbon-fiber axles potentially costing up to 3 times more than traditional steel ones.

- Integrated Designs: With the advent of electric vehicles (EVs), we’re seeing axles integrated with motors in some designs, offering more compact solutions and direct power delivery.

- Adaptive Axles: Future axles might come equipped with sensors and adaptive mechanisms that can adjust their behavior based on driving conditions, enhancing efficiency and safety.

How electric and autonomous vehicles are changing axle requirements

The rise of electric and autonomous vehicles is reshaping the landscape of automotive design, and axles are at the forefront of this transformation.

- Electric Vehicles (EVs): EVs often utilize a different drivetrain layout compared to traditional vehicles. Some EVs employ individual motors for each wheel, essentially merging the motor and axle. This design can offer precise control over each wheel, enhancing efficiency, torque delivery, and handling.

- Battery Weight: EVs come with heavy battery packs. This additional weight requires axles to bear more load, demanding stronger and more durable designs without compromising on efficiency.

- Autonomous Vehicles: As vehicles move towards higher levels of autonomy, the importance of integrating sensors and communication modules into axles increases. These additions can provide real-time feedback, ensuring safer and more efficient autonomous driving.

- Dynamic Load Adjustment: In the future, autonomous vehicles equipped with advanced axles might adjust weight distribution dynamically, based on passenger count and their positioning, enhancing stability and safety.

Advantages:

- Enhanced efficiency due to direct power delivery in EVs.

- Improved safety through integrated sensors and adaptive mechanisms in autonomous vehicles.

Disadvantages:

- Higher initial costs due to the use of advanced materials and integrated technologies.

Conclusion

As we journey through the intricate world of automobile design and engineering, it’s evident that the humble axle, though often overlooked, plays a pivotal role in shaping our driving experience.

Recap of the importance and role of axles in cars

Axles have been an integral component of vehicles since the advent of the wheel. They bear the weight of the vehicle, ensuring stability and balance, and transmit power from the engine to the wheels, enabling motion. Whether navigating the rough terrains of off-road trails or the smooth asphalt of urban highways, axles ensure our ride is safe and comfortable. Moreover, with the continuous advancements in materials and design, axles have evolved to cater to a wide range of vehicle weights, from lightweight sedans to heavy-duty trucks, each requiring specific axle specifications and designs.

Final thoughts on the future of axles in the automobile industry

The automotive landscape is rapidly transforming. As we transition to electric and autonomous vehicles, the requirements and designs of axles are set to undergo significant changes. We’re already witnessing the integration of motors with axles in some electric vehicle designs, offering enhanced efficiency and direct power delivery. Furthermore, with the added weight of batteries in EVs, axles will need to be even more robust, all while maintaining, if not reducing, their current weight to optimize efficiency.

Autonomous vehicles, on the other hand, demand axles equipped with sensors and adaptive systems, ensuring safety and precision in a world where cars drive themselves.

In essence, the axle, a component as old as the wheel itself, continues to be a cornerstone of vehicular design and innovation. Its evolution mirrors the broader shifts in the automotive industry, and as we look to the future, it’s clear that the axle will remain at the heart of our mobility, adapting and innovating in the face of new challenges and opportunities.

In sum, while the world of automobiles continues to evolve at a breakneck pace, the axle’s significance remains undiminished, reminding us of the intricate balance between tradition and innovation in engineering.