A motor moves wheels by converting electrical or fuel energy into mechanical torque, driving wheel rotation.

Basic Principles of Motors

Motors have been a foundational technology in the modern world, powering everything from tiny electronic devices to massive industrial machinery. The way they convert electrical energy into mechanical motion lies in a few basic principles, primarily rooted in electromagnetism and physics. Let’s delve into these foundational ideas.

How Motors Generate Force

At the heart of every motor is the principle of converting electrical energy into mechanical energy. This is achieved through electromagnetic fields that interact to create motion.

- Electromagnetic Induction: When an electrical current passes through a conductor, it produces a magnetic field around it. This magnetic field can push or pull on other magnetic fields or magnetized objects nearby. In the context of a motor, this pushing and pulling action is what drives movement. Here’s a Wikipedia link for further reading on electromagnetic induction.

- Armature and Commutator: In many motors, an armature (a coil or a set of coils) rotates within a magnetic field. The direction of the current in the armature is periodically reversed by a commutator, causing the armature to continually rotate, creating continuous motion.

Electromagnetism and Motion

Electromagnetism is the cornerstone of motor operation. But how does this phenomenon translate to motion?

- Magnetic Poles and Rotation: Just as like poles of a magnet repel and opposite poles attract, when electricity flows through the motor’s windings, it creates an electromagnetic field with north and south poles. By cleverly switching these poles’ orientations, the motor exploits the attraction and repulsion forces to create rotational motion. Check out this Wikipedia article on magnets to understand magnetic poles better.

- Brushed vs. Brushless Motors: While both types rely on electromagnetic principles, the primary difference is in the method of switching the current. Brushed motors use physical brushes, while brushless motors rely on electronic controllers.

Torque and Rotational Force

Torque is essentially the force that causes an object to rotate around an axis. In the realm of motors, understanding torque is crucial as it directly relates to the motor’s power and efficiency.

- Origin of Torque: In motors, torque originates from the interaction between the magnetic field produced by the stationary magnets (or windings) and the magnetic field from the current-carrying conductor, typically an armature. The greater the current, the more significant the torque produced. For a deeper understanding of torque, visit this Wikipedia page.

- Torque vs. Speed: There’s a trade-off in motors between torque and speed. Typically, as speed increases, available torque decreases, and vice versa. This relationship is essential for designing motors tailored for specific applications, whether that be high-speed tasks or high-torque demands.

Types of Motors Used in Vehicles

The automotive industry has witnessed numerous innovations in the motors that power our vehicles. From the earliest steam-powered cars to today’s sophisticated electric vehicles, the evolution of motors is a testament to human ingenuity. The type of motor chosen for a particular vehicle can significantly influence its performance, efficiency, and environmental impact. Let’s explore some of the most common motor types used in vehicles today.

Electric Motors

Electric vehicles (EVs) are gaining popularity due to their potential to reduce greenhouse gas emissions. At the heart of every EV is its electric motor, which directly converts electrical energy into motion. Two common types of electric motors are:

Brushed DC Motors

Brushed DC motors are among the simplest types of electric motors. They contain brushes that physically make contact with a rotating commutator, switching the current’s direction and maintaining continuous rotation.

- Advantages: They are cost-effective and simple in design.

- Drawbacks: The brushes wear out over time and can cause energy losses due to friction. Their efficiency isn’t as high as their brushless counterparts. Dive into the details of brushed motors on Wikipedia.

Brushless DC Motors

In contrast, brushless DC motors use an electronic controller to switch the current’s direction, eliminating the need for physical brushes.

- Advantages: Higher efficiency, longer lifespan, and reduced maintenance compared to brushed motors.

- Drawbacks: Generally more expensive due to the complex electronic control systems. For a comprehensive understanding, refer to this Wikipedia link.

Internal Combustion Engines

For over a century, internal combustion engines (ICE) have dominated the automotive landscape. They work by burning fuel within an engine to produce a high-temperature, high-pressure gas that pushes a piston, which then turns a crankshaft.

Gasoline Engines

Gasoline Engines

Gasoline engines, often just called petrol engines outside of North America, are the most common type of ICE found in passenger vehicles.

- Advantages: Relatively high power-to-weight ratio, widespread refueling infrastructure, and rapid refueling.

- Drawbacks: Produces greenhouse gases and is dependent on fossil fuels. Learn more about gasoline engines on Wikipedia.

Diesel Engines

Diesel engines operate on a similar principle as gasoline engines but use diesel fuel, which has a higher energy density.

- Advantages: Typically more fuel-efficient and have a longer lifespan than gasoline engines.

- Drawbacks: Tend to produce more nitrogen oxides and particulates, which can have adverse environmental effects. For more insights, check Wikipedia’s page on diesel engines.

Hybrid Systems

Hybrid vehicles combine the strengths of both ICEs and electric motors to enhance fuel efficiency and reduce emissions.

- Advantages: Provides better fuel efficiency, reduces greenhouse gas emissions compared to traditional ICE vehicles, and can benefit from existing gasoline or diesel infrastructure.

- Drawbacks: Can be more expensive than traditional vehicles due to the complexity of having two power systems. For more on hybrid systems, see Wikipedia.

Mechanical Linkage: From Motor to Wheel

The raw power generated by a motor is only the first step in propelling a vehicle forward. To effectively transfer this power to the wheels and then onto the road, a series of mechanical components work in harmony. Understanding these components and their functions gives insight into the intricacies of automotive design and engineering.

Transmission Systems

The transmission is a central component that adapts the output of the motor to the needs of the wheels, ensuring the vehicle moves at the desired speed while maintaining an efficient engine operation.

Manual Transmission

A manual transmission allows the driver to select the appropriate gear ratio for the driving conditions by manually shifting gears.

- Advantages: Gives the driver more control, generally more efficient, and often results in a more engaged driving experience.

- Drawbacks: Requires more attention and skill from the driver, can be difficult to use in stop-and-go traffic. Learn more about manual transmissions on Wikipedia.

Automatic Transmission

Automatic transmissions do the gear shifting work for the driver, adjusting gear ratios seamlessly based on driving conditions and engine demands.

- Advantages: Easier to use, especially in heavy traffic conditions, and can be more comfortable for many drivers.

- Drawbacks: Typically less efficient than manual transmissions and can be more expensive to repair. Dive deeper into the workings of automatic transmissions on Wikipedia.

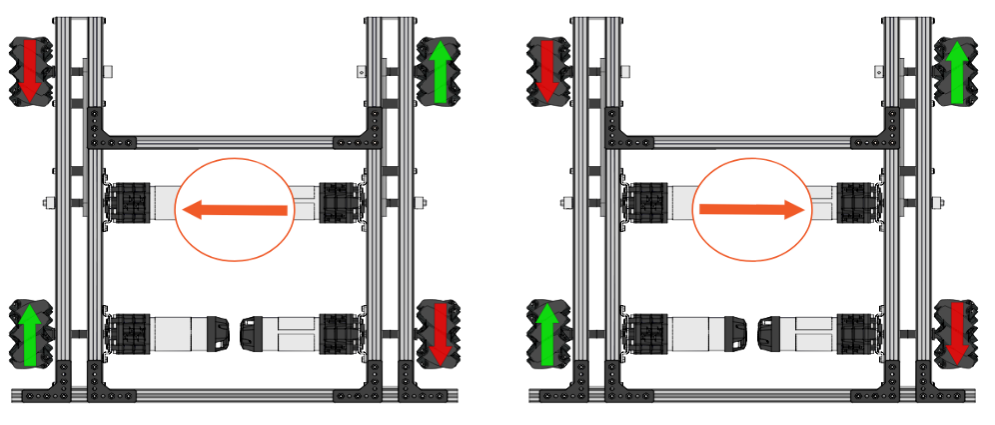

Differential

The differential is a device that allows the wheels on the same axle to rotate at different speeds, crucial for turns when the outer wheel travels a greater distance than the inner wheel.

- Advantages: Provides better handling during turns, reduces wear on the tires, and prevents wheel skidding.

- Drawbacks: Adds complexity to the drivetrain, and some types may not distribute power equally under all conditions. Get more insights about differentials on Wikipedia.

Drive Shaft and Axles

The drive shaft transfers power from the transmission to the differential, while the axles carry this power from the differential to the wheels.

- Advantages: Efficiently transfers power, provides flexibility in vehicle design, and allows for variations in distance between engine, transmission, and wheels.

- Drawbacks: Components can wear out over time and may require maintenance or replacement. For a deeper understanding of the drive shaft’s role, check out its Wikipedia page.

Efficiency and Performance

Efficiency and performance have always been focal points in the world of vehicles and machinery. As our technological capabilities expand, so do our demands for machines that perform better and waste less energy. This pursuit of perfection takes into account multiple facets of design and engineering, ranging from the core motor itself to the peripheral components like wheels.

Factors Affecting Motor Efficiency

The efficiency of a motor is pivotal in determining the performance of a vehicle. Higher efficiency translates to more output for the same input, meaning less wasted energy.

- Frictional Losses: Internal components in contact, like gears and bearings, cause friction, which leads to energy being dissipated as heat. Regular maintenance and the use of high-quality lubricants can mitigate these losses. Read more about friction on Wikipedia.

- Electrical Losses: In electric motors, electrical energy can be lost due to resistance in the windings and other components. Using conductive materials and optimized designs can help reduce these losses.

- Aerodynamic and Rolling Resistance: The shape of a vehicle and the contact of wheels with the road can also impact efficiency. Aerodynamic designs and tire choices can play a significant role here.

Improvements in Motor Technology

As technology progresses, innovations in motor designs and materials lead to enhancements in efficiency and performance.

- Advanced Materials: The introduction of new, lighter, and stronger materials can reduce the weight of components, leading to better efficiency. Furthermore, superconductors, when applicable, can drastically reduce electrical losses.

- Smart Controls: Modern motors often come equipped with advanced control systems that optimize performance under various conditions, leading to enhanced efficiency and responsiveness. Delve into smart motor control on Wikipedia.

- Integration with Renewable Energy: Especially in the context of electric vehicles, integrating motors with renewable energy sources like solar or wind can significantly improve the overall efficiency and sustainability of the system.

How Wheel Design Affects Movement

The wheels are the final link in the chain, transferring all the generated power to the road. Their design has a profound impact on a vehicle’s efficiency and performance.

- Tire Tread and Compound: Different treads are designed for different conditions, from smooth highways to rugged off-road terrains. The material or compound of the tire can influence grip, longevity, and rolling resistance.

- Wheel Weight and Distribution: A lighter wheel can improve acceleration and fuel efficiency, while weight distribution affects balance and handling.

- Aerodynamics: In high-speed vehicles, even the design of rims and spokes can have aerodynamic implications, influencing fuel consumption and stability.

Challenges and Limitations

In the pursuit of perfecting vehicle and machinery performance, engineers and designers face a multitude of challenges and limitations. Addressing these challenges is crucial not only for achieving maximum efficiency but also for ensuring long-term sustainability and minimal environmental impact. By understanding these hurdles, one can appreciate the complexities behind even the most common of our transport mechanisms.

Friction and Wear

No system is immune to the effects of friction, and with friction comes wear. These two intertwined phenomena present a constant challenge.

- Material Degradation: Continuous contact between moving parts, like gears or bearings, leads to material degradation over time, affecting performance and requiring replacements or repairs.

- Heat Generation: Friction generates heat. Excessive heat can be detrimental to many components, leading to reduced efficiency or even failure.

- Solutions: Innovations such as advanced lubricants or materials with superior wear resistance can mitigate some of the effects of friction. Dive deeper into the topic of friction on Wikipedia.

Energy Losses

Energy loss is an inherent challenge in any system, and minimizing it is essential for achieving optimal efficiency.

- Electrical Resistance: Electric motors and systems face losses due to resistance in their circuitry. Using conductive materials and optimized designs can help reduce these losses.

- Vibrations: Unwanted vibrations in machinery can lead to energy being wasted as noise or unnecessary movement.

- Solutions: Incorporating efficient designs, insulation techniques, and advanced materials can help in curbing these losses. For a comprehensive view on energy conservation, check out Wikipedia.

Environmental Considerations

As global environmental consciousness rises, the impact of vehicles and machinery on the environment comes under scrutiny.

- Emissions: Traditional combustion engines release harmful pollutants that contribute to issues like smog or global warming. Transitioning to cleaner fuel sources or electric motors can address this concern.

- Resource Consumption: The production of vehicles and machinery often involves materials that are finite or have significant environmental extraction impacts.

- Noise Pollution: Beyond just emissions, the noise produced by vehicles, especially in urban settings, is an environmental concern.

- Solutions: Eco-friendly designs, the use of sustainable materials, and the integration of green technologies are steps towards addressing these challenges.

Future Innovations in Motor-Wheel Movement

As the world advances, the realm of motor-wheel movement isn’t standing still. With increasing technological breakthroughs and a shifting emphasis towards sustainable practices, we’re on the verge of entering a new era for vehicles and machinery. From electric powerhouses to self-driving tech, the roads of the future will be a testament to human ingenuity.

Electrification and the Rise of EVs

Electrification stands at the forefront of automotive evolution, promising cleaner and more efficient transportation.

- Battery Advancements: The heart of an electric vehicle (EV) lies in its battery. Advancements in battery technology promise longer ranges, shorter charging times, and increased lifespans.

- Infrastructure Development: The rise of EVs also emphasizes the need for widespread charging infrastructure. Future cities will prioritize EV-friendly amenities to support this transition.

- Benefits: Apart from environmental benefits, EVs offer smoother acceleration, fewer moving parts (leading to less maintenance), and potential for novel design structures. For a broader perspective on EVs, visit Wikipedia.

Smart Wheel Technologies

Modern wheels aren’t just passive components. With the integration of tech, they’re turning “smart” and offering more than just rotation.

- Active Tread Patterns: Imagine a tire that changes its tread pattern based on the road condition, adapting in real-time for optimal grip and performance.

- Integrated Sensors: Future wheels could have integrated sensors to provide real-time data on wear, pressure, and even road conditions, feeding this data to the vehicle’s systems for optimized performance.

- Energy Regeneration: Some designs propose using wheels as a source of energy regeneration, capturing the energy typically lost during braking. Dive into the realm of regenerative braking on Wikipedia.

Autonomous Vehicles and Advanced Propulsion

Self-driving vehicles represent the pinnacle of automation, promising to redefine our relationship with transportation.

- Sensor Fusion: Autonomous vehicles rely on a plethora of sensors – from cameras to LIDAR – that work in tandem to interpret and react to the environment.

- Machine Learning and AI: These vehicles leverage sophisticated algorithms and machine learning models to make driving decisions, promising safer and more efficient roadways.

- Magnetic Propulsion: Looking even further ahead, concepts like magnetic propulsion or levitation could redefine movement, making wheels obsolete in some contexts.

Gasoline Engines

Gasoline Engines