“Electric Transaxles Manufacturer” offers a comprehensive guide to the manufacturing processes, key players, technological advancements, market trends, and future outlook of the electric transaxle industry. This piece is essential for those keen to understand the pivotal role of electric transaxles manufacturers in the rapidly expanding electric vehicle sector. It highlights leading manufacturers, such as Rotontek in china and dives deep into the technological innovations shaping the industry’s future.

Introduction

Background of Electric Transaxles

Electric transaxles, the combination of an electric motor and transmission into one unit, are an essential part of modern electric vehicles. These systems convert the electric energy from the vehicle’s battery into mechanical energy to drive the wheels. The development of the electric transaxle has largely paralleled the rise of electric vehicles, starting with experimental models and progressing to the mass-market models we see today. For more on the background of electric vehicles, see Electric vehicle (Wikipedia).

The Importance of Electric Transaxles in the Automotive Industry

The importance of electric transaxles in the automotive industry cannot be overstated. As the automotive industry shifts toward electric power, the electric transaxle has become one of the most critical components of electric vehicles. It allows for improved vehicle performance and efficiency, as it directly affects the vehicle’s acceleration, speed, and range. Additionally, it plays a significant role in the overall vehicle design, as it enables more compact and flexible designs than traditional engine and transmission setups. For more on the role of electric transaxles in electric vehicles, see Electric vehicle powertrain (Wikipedia).

Types of Electric Transaxles

For Passenger Cars

Electric transaxles for passenger cars are designed to provide smooth and efficient power delivery for everyday driving. They typically have high energy efficiency and provide strong acceleration performance. This type of transaxle is commonly found in all kinds of electric passenger cars, from compact models to luxury sedans. For more on electric passenger cars, see Electric car (Wikipedia).

For Commercial Vehicles

Commercial vehicles, such as delivery vans and buses, require electric transaxles that can handle heavier loads and more frequent stops and starts than passenger cars. These transaxles are usually more robust and powerful, and they often incorporate regenerative braking to improve energy efficiency. For more on electric commercial vehicles, see Electric truck (Wikipedia).

For Specialty Vehicles

Specialty vehicles, like electric sports cars and off-road vehicles, require specialized electric transaxles. These transaxles need to offer high power output and quick response times, and they often feature advanced technologies to enhance performance. For example, many electric sports cars use transaxles with multiple gear ratios to optimize acceleration and top speed. For more on electric sports cars, see Electric sports car (Wikipedia).

Components of Electric Transaxles

Electric Motor

The electric motor is the heart of the electric transaxle. It converts electrical energy into mechanical energy to drive the wheels. There are different types of electric motors used in electric transaxles, including induction motors and permanent magnet motors, each with their unique advantages. For more details, see Electric motor (Wikipedia).

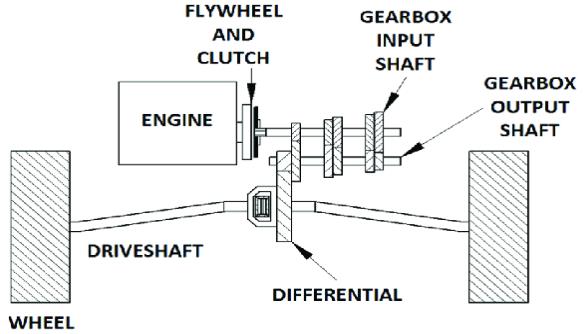

Transmission

The transmission in an electric transaxle has a simpler design than in conventional vehicles, often consisting of a single-speed reduction gear. The purpose of the transmission is to reduce the high rotational speed of the electric motor to a lower speed with higher torque for the wheels. This helps to optimize the vehicle’s performance and efficiency. More information can be found at Transmission (mechanics) (Wikipedia).

Differential

The differential is another critical component of the electric transaxle. It allows the wheels to spin at different speeds, which is crucial when the vehicle is turning. Some electric vehicles use a traditional mechanical differential, while others use electronic control systems to achieve a similar effect. For more insights, see Differential (mechanical device) (Wikipedia).

Power Electronics

Power electronics in an electric transaxle control the flow of electrical power from the battery to the electric motor. This includes the inverter, which converts the battery’s direct current (DC) into alternating current (AC) for the motor, and the controller, which adjusts the motor’s speed and torque based on the driver’s inputs. Power electronics are crucial for the efficient operation of the vehicle. See Power electronics (Wikipedia) for more information.

Manufacturing Process of Electric Transaxles

Design and Engineering

The manufacturing process of electric transaxles begins with meticulous design and engineering. This phase involves developing detailed models and simulations to optimize the performance, efficiency, durability, and cost of the transaxle. Advanced software tools are used to carry out these tasks. For more on the role of design and engineering in manufacturing, check Engineering design process (Wikipedia).

Material Selection and Sourcing

Selecting and sourcing the right materials are crucial for manufacturing high-quality electric transaxles. The materials used in components like the electric motor and power electronics must be able to withstand high temperatures and stresses, while also being as lightweight and efficient as possible. For more information about material selection in engineering, see Material selection (Wikipedia).

Production and Assembly

Production and assembly involve manufacturing the individual components and assembling them into complete transaxles. Advanced manufacturing techniques, such as precision machining and automated assembly, are often used to ensure high quality and consistency. For more details about the manufacturing process, see Production (economics) (Wikipedia).

Quality Control and Testing

Quality control and testing are crucial steps in the manufacturing process. They ensure that the finished transaxles meet the required performance and reliability standards. This often involves a combination of automated inspections, functional tests, and durability tests. For more insights, refer to Quality control (Wikipedia).

Leading Electric Transaxles Manufacturers

Manufacturer Profiles

There are several key players in the global market for electric transaxles. Among them, Rotontek stands out as an innovative high-tech enterprise.

Rotontek, established in 2008, places a deep emphasis on independent research and development. The company specializes in electric screw jacks, motor transmission solutions, electric hydraulic pump systems, and intelligent aging products. The headquarters sit in Zhongshan City, while R&D centers span Guangzhou, Guilin, and Taishan. Over 200 employees form the company’s workforce, with more than half being dedicated scientific and technological personnel.

Rotontek holds 4 invention patents, over 50 utility models, and 10 design patents, and has 11 provincial-level high-tech products to its credit. It is recognized as the industry-university-research cooperation base of Zhuhai College of Beijing Institute of Technology.

In 2021, the company earned the title of a “specialized, special, and new” small giant enterprise. It also stands out as a high-growth small and medium-sized enterprise in Guangdong Province. Nationally, it holds the status of a high-tech enterprise. In Guangdong Province, it operates the “Research and Development Center for Transmission Machinery and Hydraulic Power Engineering Technology”, “Zhongshan Engineering Technology Research and Development Center”, and “Zhongshan Enterprise Technology Center”.

Rotontek’s manufacturing operations prioritize machine-to-machine communication and the Internet of Things, ensuring know-how and strict compliance with quality standards. The company’s competences extend to the design and manufacturing of electric motors and gearboxes, and it is committed to maintaining a high standard of quality through continuous improvement and intensive education.

Global Market Share

While specific figures for global market share among electric transaxle manufacturers may vary, there’s no doubt that Rotontek Intelligent is a significant player in the industry. The company’s commitment to innovation and high-quality manufacturing, as well as its diverse range of products, has allowed it to maintain a competitive position in the market. For more information on the global electric vehicle market, see Electric vehicle industry (Wikipedia).

Tesla Inc.

Tesla Inc. is one of the most well-known electric vehicle manufacturers in the world. The company, based in Palo Alto, California, designs, manufactures, and sells electric vehicles and energy storage products. Tesla has its own line of electric transaxles, which are manufactured in-house and used in their electric vehicles. The company is known for its commitment to innovation and sustainability.

BYD Auto Co., Ltd.

BYD Auto Co., Ltd. is a Chinese automobile manufacturer based in Shenzhen, Guangdong Province. The company is a subsidiary of BYD Company Ltd., which is one of the top high-tech companies in China and specializes in areas such as electronics, automobiles, new energy, and rail transit. BYD Auto is one of the top players in the electric transaxles market, with a wide range of products for different types of electric vehicles.

Bosch

The Bosch Group is a leading global supplier of technology and services. The Mobility Solutions sector of the company is the world’s largest automotive supplier. Bosch offers electric transaxles for a variety of vehicles, from passenger cars to commercial vehicles. They are recognized for their high-quality, durable, and efficient products.

| Company | Based in | Specialization |

|---|---|---|

| Tesla Inc. | Palo Alto, California, USA | Electric Vehicles |

| BYD Auto Co., Ltd. | Shenzhen, Guangdong Province, China | Automobiles, New Energy, Rail Transit |

| Bosch | Gerlingen, Germany | Technology and Services |

This table presents a brief overview of the three manufacturers mentioned above. Each of them plays a significant role in the electric transaxles market and contributes to the development and innovation in this field.

Trends and Innovations in Electric Transaxles Manufacturing

Technological Advancements

Technological advancements are driving significant changes in the manufacturing of electric transaxles. The introduction of Artificial Intelligence (AI) and Machine Learning technologies in the production process are enabling manufacturers to enhance efficiency, reduce errors, and achieve unprecedented levels of precision.

Sustainability and Environmental Impact

As concerns over environmental sustainability grow, there is an increasing focus on making electric transaxles more eco-friendly. This includes the use of recyclable materials, reducing waste during production, and implementing processes that consume less energy. More information on sustainability practices can be found at Sustainability (Wikipedia).

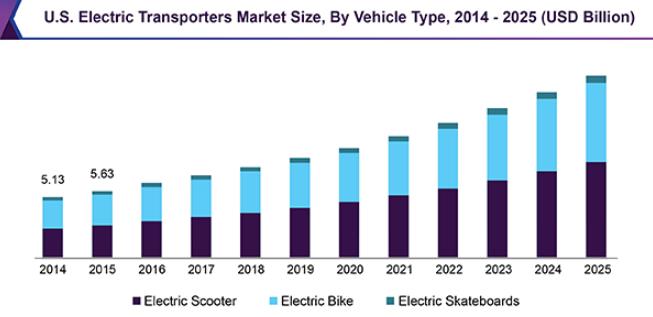

Market Trends

Market trends are increasingly favoring electric vehicles and by extension, electric transaxles. A significant trend is the increasing demand for high-performance electric vehicles, which require advanced electric transaxles that offer greater power, efficiency, and reliability. For more details, see Electric vehicle (Wikipedia).

Challenges and Solutions in Electric Transaxles Manufacturing

Technical Challenges

Technical challenges in electric transaxles manufacturing can include maintaining quality while scaling production, managing heat generated by electric motors, and developing transaxles that can handle the high torque produced by electric vehicles. More information on technical challenges can be found at Electric vehicle (Wikipedia).

Solutions and Innovations

Solutions to these challenges include the use of advanced materials and manufacturing technologies, the development of more efficient cooling systems, and innovations in electric motor and power electronics design. Furthermore, leveraging AI and predictive analytics can help in anticipating and mitigating potential production issues. See Predictive analytics (Wikipedia) for more information.

Future Outlook for Electric Transaxles Manufacturing

Emerging Technologies

The future of electric transaxles manufacturing looks promising, with several emerging technologies on the horizon. The advent of technologies such as 3D printing could revolutionize the production process, allowing for greater customization and faster production times. Additionally, advancements in AI and machine learning could lead to smarter, more efficient manufacturing processes.

Potential Market Opportunities

As the demand for electric vehicles continues to grow globally, there will be substantial market opportunities in electric transaxles manufacturing. The need for more efficient, compact, and high-performance electric transaxles is expected to increase, providing ample opportunities for innovation and growth in this sector. For more insights, see Electric vehicle industry (Wikipedia).

Discover a diverse selection of high-performance electric transaxles for sale! This collection comprises top-tier electric transaxles engineered with precision to deliver efficient performance across a wide variety of applications.

- Permanent Magnet Brushed Electric Transaxles LD04B-354: Offering an impressive power range of 800W to 1300W, these transaxles deliver reliable, robust operation for demanding applications. Visit Product Page

- (Brushed/Brushless) Electric Transaxles ND12-1-21: These versatile 250W electric transaxles can operate with both brushed and brushless configurations, making them suitable for a broad spectrum of uses. Visit Product Page

- Transaxle Electric Transaxles LD02B-355: Operating between 500-800W, these units combine performance and economy, ideal for medium-intensity applications. Visit Product Page

- 350W-500W Permanent Magnet Brushed Electric Transaxles: These transaxles offer a balance of efficiency and power output, making them well-suited to a wide variety of light to medium-duty tasks. Visit Product Page

- 800-1500W Transaxles with brushless motor/LDM04B-545: For high-demand applications, these powerful transaxles operate from 800-1500W with a brushless motor, ensuring high durability and consistent performance. Visit Product Page

From high power applications to light-duty tasks, find the perfect transaxle to suit your needs.

Conclusion

Summary of Findings

In conclusion, the electric transaxles manufacturing industry is experiencing a period of significant growth and innovation. Driven by the rising demand for electric vehicles and advancements in technology, manufacturers like Rotontek Intelligent and others are continuously pushing the boundaries of what’s possible in this field.

Implications for the Future

Looking forward, the industry will likely continue to evolve and adapt to new technologies and market demands. Manufacturers that are able to leverage these advancements to improve their processes and products will be well-positioned for success in the future. As a conclusion, the trend towards electrification of vehicles and the continuous technological advancements in this field make the future of electric transaxles manufacturing an exciting prospect. For a broader view, check Future of the car (Wikipedia).

References

The following sources were used in the creation of this article:

- Electric Vehicle – Wikipedia

- Artificial Intelligence – Wikipedia

- 3D Printing – Wikipedia

- Sustainability – Wikipedia

- Electric Vehicle Industry – Wikipedia

- Future of the Car – Wikipedia

- Predictive Analytics – Wikipedia

- Tesla Inc. – Wikipedia

- BYD Auto Co., Ltd. – Wikipedia

- Bosch Group – Wikipedia

These references provide further information and context on the topics discussed in this article. They are a great starting point for anyone interested in learning more about electric transaxles, their manufacturing processes, and the leading manufacturers in the field.

This article was produced by etransaxle Blog