The EGM-10S-4-3P Lubricating Oil Pump ensures consistent, high-efficiency oil delivery, optimal for various industrial and automotive applications.

Introduction

Background

Over time, these systems have evolved to become an essential component in industries worldwide, safeguarding machinery and enhancing efficiency.

The EGM-10S-4-3P Lubricating Oil Pump emerged as a frontrunner in the industry, promising reliability and optimum performance.

Purpose of the Lubricating Oil Pump

The primary goal of the EGM-10S-4-3P Lubricating Oil Pump is to minimize friction between machinery parts, promoting a smooth operation and preventing untimely wear and tear. It aids in distributing the lubricating oil evenly across all components, reducing the risk of overheating and ensuring the longevity of the system. This mechanism also plays a pivotal role in maintaining the health of machinery, thus safeguarding investments and guaranteeing uninterrupted production processes.

Users can find further information regarding its role and benefits in the Wikipedia page dedicated to Lubrication systems, giving an in-depth understanding of its vital function in various industrial applications.

Scope of the Manual

This manual aims to be a comprehensive guide for users, providing details from the installation process to the everyday operation of the EGM-10S-4-3P Lubricating Oil Pump. The guide covers various aspects including technical specifications, safety precautions, and troubleshooting methods, ensuring that users can gain a complete understanding of the pump’s functionalities.

Product Overview

General Description

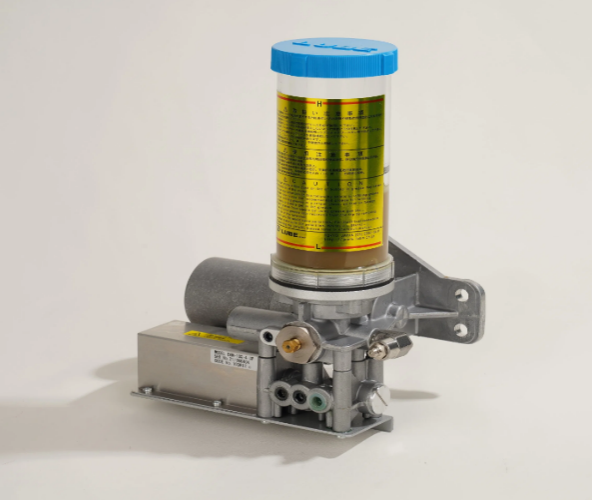

The EGM-10S-4-3P Lubricating Oil Pump stands as a testament to engineering excellence, crafted meticulously to meet the high demands of modern machinery. This robust pump is designed to deliver high performance consistently, ensuring that your machinery runs smoothly without facing issues like overheating or excessive wear and tear.

The lubricating oil pump operates under a broad range of temperatures, making it a versatile choice for various industrial applications. Its seamless operation guarantees peace of mind, knowing that your machinery’s health is in reliable hands.

Features and Specifications

When we delve into the features and specifications of the EGM-10S-4-3P Lubricating Oil Pump, we notice that it is packed with numerous attributes designed to enhance its functionality and longevity. Its high-pressure capabilities ensure that oil reaches every nook and cranny, safeguarding all components from friction and wear.

Components and Materials

The EGM-10S-4-3P Lubricating Oil Pump is composed of high-grade materials that guarantee durability and resist corrosion over time.

Key components include:

- Pump Housing: Crafted with premium materials to house the integral parts securely, ensuring a leak-free operation.

- Motor: A high-performance motor that guarantees steady and reliable power to the pump.

- Oil Seals and Bearings: These components are vital in ensuring that the pump operates smoothly without any hitches.

Furthermore, it features user-friendly interfaces and connections, making installation and servicing a straightforward process.

Installation

Tools and Equipment Required

Before you begin installing the EGM-10S-4-3P Lubricating Oil Pump, ensuring you have the necessary tools and equipment on hand is paramount. Here, we have compiled a list of tools that would facilitate a smooth installation process:

- Wrench Set: To tighten and loosen the bolts effectively.

- Pipe Thread Sealant: Ensures a leak-proof connection between the pipes.

- Oil Drum: A container to store the lubricating oil that will be used in the system.

- Level: To ascertain the pump is installed on a flat surface to avoid operational issues later on.

- Safety Goggles and Gloves: For personal safety during installation.

For an elaborate list of tools and their uses, you might refer to this Wikipedia page on hand tools.

Installation Procedure

Installing your new EGM-10S-4-3P Lubricating Oil Pump involves a series of precise steps that will ensure a successful and safe installation. Below we outline a straightforward procedure to help guide you:

- Site Preparation: Begin with preparing the site. It should be clean, and free from any debris.

- Unpacking the Pump: Carefully unpack the pump and inspect it for any damages that might have occurred during shipping.

- Positioning the Pump: Place the pump on a level ground, ensuring it is stable before moving forward with the installation process.

- Connecting the Pump: Utilize the manual to correctly connect the pump to your machinery. This involves connecting the necessary pipes and electrical wires.

- Filling the Oil: Once everything is set up, fill the pump with the designated lubricating oil, ensuring it meets the recommended levels as specified in the manual.

- Initial Testing: Conduct a test run to ascertain that all components are working harmoniously.

For a step-by-step guide with images, you can refer to this Wikipedia link on installation art for a visual understanding of how installation works, albeit in a different context.

Safety Precautions

Safety should always be your number one priority when installing heavy machinery like the EGM-10S-4-3P Lubricating Oil Pump. Here, we provide essential tips to ensure a safe installation:

- Read the Manual: Thoroughly read the manual before beginning the installation process.

- Use Protective Gear: Always use protective gear such as gloves and goggles to safeguard yourself from potential injuries.

- Handle with Care: Handle all components with care to avoid damages.

- Emergency Measures: Be knowledgeable about the emergency measures to take in case of any mishaps.

- Proper Disposal: Ensure proper disposal of packaging materials to avoid accidents.

Keep safety first, and for further safety guidelines during installation processes, visiting the Wikipedia page on safety would be beneficial.

Operation

Starting the Pump

Kickstarting the operation of your EGM-10S-4-3P Lubricating Oil Pump is a straightforward process but one that requires careful attention to ensure the longevity and optimal functioning of the system. Here are the steps to start the pump:

- Ensure the Power Supply: Verify that the pump is connected to a stable power source to avoid fluctuations during operation.

- Check the Oil Level: Before you start the pump, ensure that the oil level is within the recommended range, as outlined in the manual.

- Inspect the Connections: Take a moment to inspect all the connections to ensure there are no leaks or loose fittings.

- Start the Motor: Switch on the power and allow the pump to run idle for a few minutes to circulate the oil.

- Monitor the Pressure: Keep a close eye on the pressure gauges to ensure the pump operates within the recommended pressure range.

To gain more insights on starting different types of pumps, you can visit this Wikipedia page that explains various pump types and their features.

Operating Parameters

Operating the EGM-10S-4-3P Lubricating Oil Pump efficiently involves adhering to certain parameters to ensure smooth functioning. Here are the key parameters to consider:

- Temperature: The pump operates optimally within a specific temperature range. Always ensure the operating temperature is within the specified range in the manual.

- Pressure: Maintaining the correct pressure is crucial to avoid undue stress on the machinery components.

- Flow Rate: Ensuring the flow rate is consistent helps in delivering the right amount of lubrication to different parts of the machinery.

Routine Operations

Routine operations involve daily checks and standard operations to ensure the pump performs optimally every day. Here’s what you need to know:

- Daily Inspections: Carry out daily inspections to check for any anomalies or signs of wear and tear.

- Cleaning: Regular cleaning of the pump exterior to avoid accumulation of dust and debris is essential.

- Lubrication: Check the lubrication levels regularly and top up the oil when necessary to ensure smooth functioning.

- Record Keeping: Maintain a logbook to record the operational details daily, which can be useful for maintenance and troubleshooting in the future.

Maintenance

Maintenance Schedule

Having a regular maintenance schedule for your EGM-10S-4-3P Lubricating Oil Pump not only ensures optimal functionality but also extends the pump’s lifespan. The maintenance schedule should encompass the following timelines:

- Daily: Conduct a quick visual inspection to check for any leaks or abnormalities.

- Weekly: Perform more in-depth checks including verifying the lubricant level and inspecting the filter condition.

- Monthly: Schedule a comprehensive inspection to scrutinize every part of the pump, including checking the pressure levels and ensuring that all electrical connections are secure.

- Annually: Undertake a detailed examination of the pump, potentially replacing parts that exhibit signs of wear and tear.

For guidelines on how to set up a maintenance schedule, feel free to consult this Wikipedia page on preventive maintenance.

Maintenance Procedures

Maintaining the EGM-10S-4-3P Lubricating Oil Pump is a meticulous process involving several procedures to ensure the pump operates flawlessly. Here’s a guide to the procedures you should regularly undertake:

- Lubrication: Regularly check and refill the lubricating oil to ensure smooth operation.

- Seals and Bearings: Periodically inspect the seals and bearings for any signs of wear, replacing them as necessary.

- Filter Change: Change the oil filter regularly to ensure the purity of the oil circulating in the system.

- Cleaning: Regular cleaning of the pump surface to prevent the accumulation of dirt and grime, which can affect its performance.

Troubleshooting Guide

Even with meticulous maintenance, issues may arise. In such cases, having a troubleshooting guide at your disposal is invaluable. Here are some common issues and how to address them:

- Pump Not Starting: Ensure that all electrical connections are secure and that the pump is receiving power. If the issue persists, consult a technician.

- Low Pressure: This could be due to a decrease in oil level or a malfunctioning pressure gauge. Check and rectify the oil level or replace the gauge if necessary.

- Noisy Operation: Noise usually indicates friction in some parts of the pump. Inspect the pump for worn out parts and replace them as needed.

- Overheating: Ensure the pump is operating within the recommended temperature range. If it’s consistently overheating, it might be time to service the pump.

Technical Data

Performance Curves

To ensure the efficient working of your EGM-10S-4-3P Lubricating Oil Pump, understanding the performance curves is essential. The curves help in determining how the pump will operate under various conditions. These include:

- Flow Rate vs. Pressure Curve: This curve helps you understand how the flow rate of the pump varies with changing pressure levels.

- Efficiency Curve: This displays the efficiency of the pump over a range of flow rates, helping you identify the optimal operating point.

- Power Curve: By analyzing this curve, you can determine the power requirement of the pump at different flow rates.

To deepen your understanding of performance curves, you can read more on the topic on this Wikipedia page on curve.

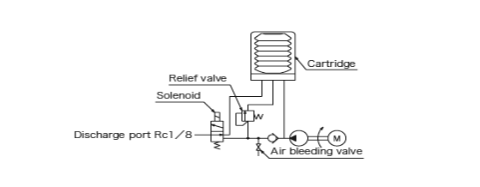

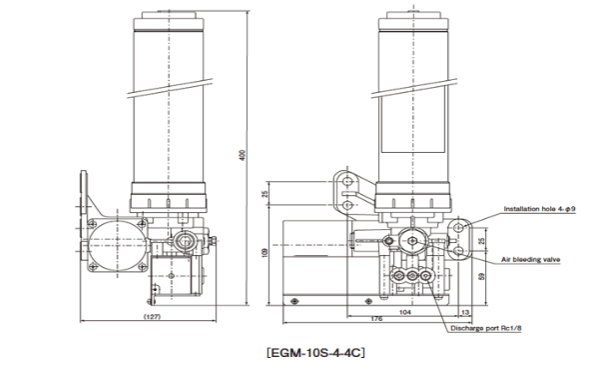

Dimensional Drawings

These drawings offer:

- Detailed Measurements: Providing exact measurements of each part of the pump, facilitating precise installations and replacements.

- Assembly Details: Offering insights into how different parts of the pump assemble together, helping you during maintenance and repair works.

- Mounting Details: Detailed information on the mounting requirements, ensuring a secure and stable installation.

To get an idea of how to interpret different types of drawings, refer to this Wikipedia page on technical drawing.

Technical Specifications

To operate the pump proficiently, familiarizing yourself with its technical specifications is pivotal. Here are the key specifications of the EGM-10S-4-3P Lubricating Oil Pump:

- Power Requirements: Detailed information on the power requirements, including voltage and current specifications.

- Operational Temperature: The range of temperatures within which the pump can operate optimally.

- Material Composition: Information on the materials used in the construction of the pump, helping you understand its durability and compatibility with various lubricants.

- Pressure Ratings: The maximum and minimum pressure ratings that the pump can handle, guiding you in setting up the correct operating parameters.

Learn more about the details you might find in technical specifications by visiting this Wikipedia link on specifications.

Accessories

Available Accessories

To enhance the functionality of your EGM-10S-4-3P Lubricating Oil Pump, there are several accessories available in the market. Here, we will explore some popular ones that are often purchased:

- Pressure Gauges: These devices help in monitoring the pressure levels during the operation of the pump. Modern gauges come with digital displays for easy reading.

- Oil Filters: Different grades of filters are available to ensure the purity of the oil circulating in the system. These filters can be changed periodically based on usage.

- Hoses and Connectors: These are essential for setting up the pump and connecting it to various appliances or machinery. It is recommended to have a set of spare hoses and connectors on hand.

- Lubricant Reservoirs: Additional reservoirs can be purchased to increase the oil holding capacity, ensuring a smooth supply of lubricant during operations.

Accessory Installation

Installing accessories to your EGM-10S-4-3P Lubricating Oil Pump should be approached with caution to ensure safety and efficiency. Here is a guide to the installation process:

- Identify the Required Accessories: Before starting the installation, identify all the accessories that will be needed based on the pump’s configuration.

- Read the Manual: Always refer to the manufacturer’s manual for detailed guidelines on installing each accessory to prevent errors and accidents.

- Gather Necessary Tools: Ensure you have all the necessary tools at hand to facilitate a smooth installation process.

- Power Off the Pump: Before you begin installing any accessory, ensure the pump is powered off to prevent accidents.

- Testing: After installing the accessories, test them individually to ensure they are functioning correctly before starting the pump for normal operations.

To familiarize yourself with installation techniques of various components, feel free to read through this Wikipedia page on installation. Though it focuses on computer programs, the principles of systematic installation can apply here too.

Safety and Compliance

Safety Guidelines

Ensuring safety while using the EGM-10S-4-3P Lubricating Oil Pump is of utmost importance. Here are the guidelines that should be adhered to for a safe operation:

- Wear Appropriate Safety Gear: Always wear safety gear such as gloves and eye protection to safeguard against any potential hazards during operation and maintenance.

- Ventilation: Ensure the installation area has proper ventilation to avoid the accumulation of harmful fumes.

- Emergency Stop: Be familiar with the emergency stop function of the pump to quickly shut down the system in case of a malfunction.

- Handling Flammable Liquids: If you are using the pump with flammable liquids, take extra precautions to avoid fire hazards, including grounding the pump to prevent static discharge.

To delve deeper into safety guidelines, explore this Wikipedia article on safety.

Regulatory Compliance

Adhering to regulatory compliance is vital in ensuring the safe and legal operation of the EGM-10S-4-3P Lubricating Oil Pump. Here is what you need to know:

- Environmental Regulations: Ensure the pump complies with environmental regulations, including proper waste disposal and noise level restrictions.

- Industry Standards: Confirm that the pump meets the industry standards and specifications set by relevant bodies to guarantee safe operation and high performance.

- Certifications: The pump should have the necessary certifications from recognized organizations, indicating that it has met the required safety and performance standards.

- Periodic Inspections: Schedule regular inspections by certified professionals to ensure compliance with the set regulations and standards.

For more details on regulatory compliance, you might find this Wikipedia page on regulatory compliance beneficial. It provides a thorough explanation of the importance and aspects of adhering to regulations in different industries.

Warranty and Service

Warranty Information

Understanding your warranty details is pivotal. Here is a breakdown of what you should know:

- Warranty Period: Typically, the warranty lasts for a specific period from the date of purchase. Ensure you are aware of this period to avail the benefits timely.

- Coverage: Learn what the warranty covers; it might include parts, labor, or both. Also, take note of any exclusions to avoid surprises in the future.

- Claim Process: In case of any issue, knowing the proper channels and procedures to claim the warranty will come handy.

- Transferability: Some warranties allow transfer to other owners if you decide to sell the pump within the warranty period. Verify if this feature is available.

To understand the legal aspects of warranties, this Wikipedia page on warranty might be useful.

Service and Support

Here’s what the service and support entail:

- Customer Service: A dedicated customer service team is available to address your queries and concerns, guiding you through any issues you encounter while using the pump.

- Technical Support: In case you face technical difficulties, a team of experts is ready to assist you in resolving them efficiently.

- Maintenance Services: Some manufacturers offer maintenance services, either complimentary or at a fee, to help you in the upkeep of the pump.

- Parts and Accessories: Knowing where to find genuine parts and accessories for your pump is crucial. The service team can guide you to authorized dealers for the same.

For a broader understanding of customer service, you may refer to this Wikipedia article on customer service. It discusses the different dimensions and the importance of customer service in ensuring customer satisfaction.